Lithium ion battery diaphragm, preparation method thereof and lithium ion battery

A lithium-ion battery and diaphragm technology, applied in the field of lithium-ion battery diaphragm and its preparation, can solve the problems of small rising space for coating pores, narrow lithium analysis window, insufficient electrolyte infiltration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] 2, a kind of preparation method of lithium-ion battery diaphragm, comprises the following steps:

[0050] Step (A): Prepare ceramic composite slurry: ceramic particles, thickeners, dispersants, binders, and foaming agents are prepared in a ratio of 50-99 parts by weight: 0.1-1: 0.01-1: 2-6 : 0.1-5 mixing and stirring to form a ceramic composite slurry with a solid content of 20-40%;

[0051] Step (B): Prepare the adhesive slurry: mix and stir the adhesive particles, thickener, dispersant and binder in a weight ratio of 80-95:0.1-1.5:0.01-1:0.1-5 Adhesive slurry with a solid content of 2-6%;

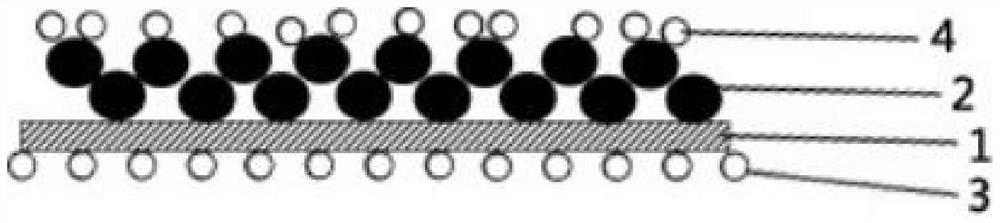

[0052] Step (C): coating a ceramic composite slurry on one surface of the base film layer 1, drying to form a ceramic composite layer 2, coating an adhesive slurry on the surface of the ceramic composite layer 2, and drying to form a first adhesive layer 3, The adhesive slurry is coated on the other surface of the base film layer 1 and dried to form a second adhesive layer 4 to o...

Embodiment 1

[0069] (1) Preparation of positive electrode sheet

[0070] Mix NCM811 positive electrode active material, conductive agent superconducting carbon and carbon tubes, and binder polyvinylidene fluoride at a mass ratio of 96:2.0:0.5:1.5 to make positive electrode slurry, and coat the positive electrode slurry on the current collector aluminum foil On one surface of the aluminum foil, after drying and winding at 85°C, the positive electrode slurry is coated and dried on the other side of the aluminum foil according to the above method, and then the prepared aluminum foil is double-sided coated with the positive electrode active material layer. Cold pressing treatment; edge trimming, cutting into pieces, slitting, and slitting to make lithium-ion battery cathode sheets.

[0071] (2) Preparation of negative electrode sheet

[0072] The silicon carbon negative electrode active material, the conductive agent superconducting carbon, the thickener sodium carboxymethyl cellulose, and th...

Embodiment 2

[0094] The difference from Example 1 is:

[0095] (3) Preparation of diaphragm

[0096] A preparation method of a lithium-ion battery diaphragm, comprising the following steps:

[0097] Step (A): Prepare ceramic composite slurry: mix and stir ceramic particles, thickener, dispersant, binder, and foaming agent in a ratio of parts by weight of 90:0.5:0.5:5:0.8 to form a solid content of 30% ceramic composite slurry;

[0098] Step (B): Prepare the adhesive slurry: mix the adhesive particles, thickener, dispersant and binder at a weight ratio of 90:0.5:0.5:4 to form an adhesive with a solid content of 5%. slurry;

[0099] Step (C): coating a ceramic composite slurry on one surface of the base film layer 1, drying to form a ceramic composite layer 2, coating an adhesive slurry on the surface of the ceramic composite layer 2, and drying to form a first adhesive layer 3, The adhesive slurry is coated on the other surface of the base film layer 1 and dried to form a second adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com