Rod processing device

A bar material processing and bar material technology, applied in the field of bar material processing devices, can solve the problems of low processing efficiency, high labor intensity of workers, safety risks, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

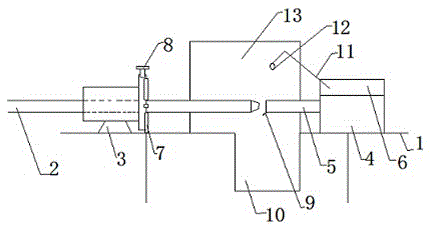

[0008] Such as figure 1 As shown, a bar processing device of the present invention is driven by a motor 1, drives the flywheel 2 on the main shaft through a belt transmission 9, and transmits the rotational motion to the pinion 3 through the main shaft, meshes with the large gear 4, and uses an electromagnet 8 , control the clutch 5, so that the crankshaft 6 and the large gear 4 move synchronously, the crankshaft drives the slider 7 to move up and down, the bar cutting tool is installed on the slider, and follows the movement of the slider to realize bar cutting. The motor 1 is used as the drive to realize the conversion of a certain transmission ratio through the worm gear 10, and drives the sprocket 11 to rotate through the chain transmission, and at the same time makes the roller 12 move coaxially, and realizes material support under the joint action of the auxiliary roller 12. At the same time, it also Under the pressing force of the roller 12, the feeding movement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com