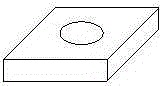

Magnetic core for suppressor

A suppressor and magnetic core technology, applied in the field of magnetic cores, can solve the problems of high production cost, complex shape, and low product qualification rate, and achieve the effect of solving easy deformation, simple shape, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A magnetic core for a suppressor, the cuboid magnetic core has a round hole, and the magnetic core is sintered from ferrite material, or pressed from metal soft magnetic powder. The magnetic core can be pressed and formed with the simplest mold, and because of its simple shape, multiple pieces can be molded in one mold, which greatly improves production efficiency. The invention also effectively solves the problems that the traditional magnetic core is easily deformed and the qualified rate of products is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com