Internal step-down circuit structure of LED driving power source

A technology of LED drive and step-down circuit, applied in electric light source, electroluminescence light source, light source and other directions, can solve the problems of not easy to integrate in the chip, large circuit size, etc., achieve small electromagnetic interference, small size, wide voltage range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

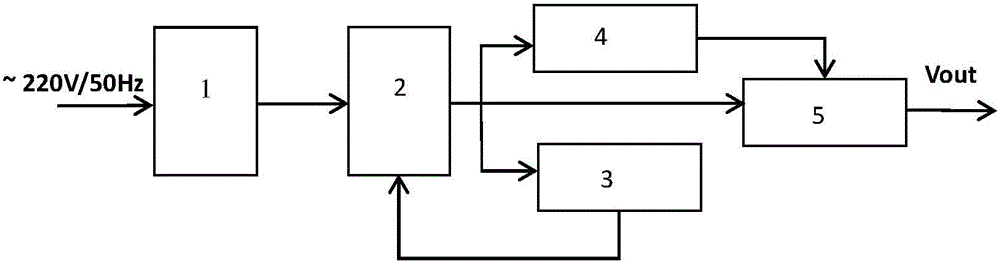

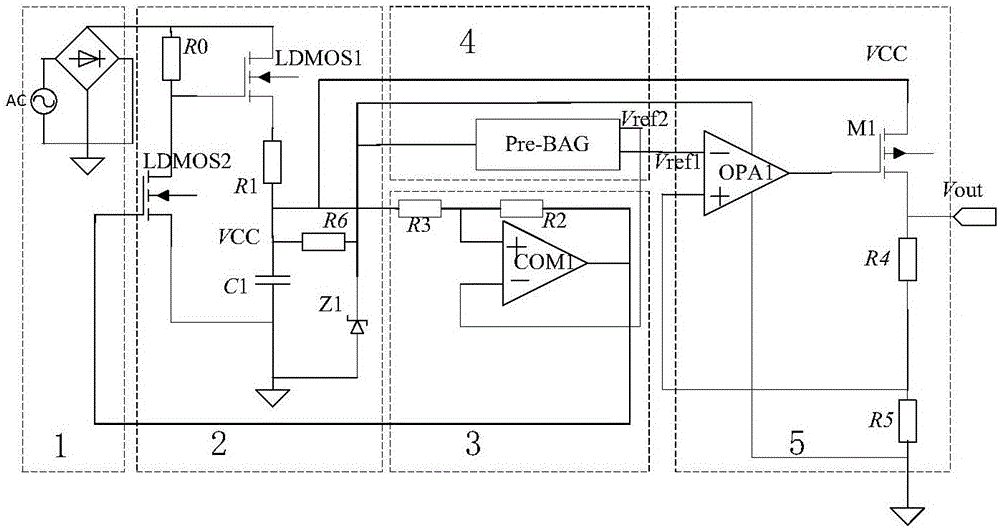

[0021] An internal step-down circuit structure of an LED drive power supply (see figure 1 ),it includes:

[0022] Rectifier bridge circuit 1: perform full-wave rectification on the 220V, 50Hz sinusoidal voltage waveform to obtain a 0-311V DC pulsating voltage, which is connected to the high-voltage pre-step-down circuit 2;

[0023] High-voltage pre-decompression circuit 2: step down the DC pulsating voltage output by rectifier bridge circuit 1, and connect with linear voltage stabilizing circuit 5, hysteresis detection circuit 3 and pre-reference voltage circuit 4;

[0024] Hysteresis detection circuit 3: by detecting and comparing the voltage of the high-voltage pre-depressor circuit 2, controlling the on-off of the high-voltage pre-depressor circuit 2, thereby controlling the fluctuation range of the pre-depressor voltage;

[0025] Pre-reference voltage circuit 4: output a reference voltage that does not vary with input power fluctuations and temperature, as a reference vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com