Hall sensor

A Hall sensor and Hall element technology, which is applied in the field of Hall sensors, can solve the problem that the magnetic offset cannot be eliminated by the offset cancellation circuit, and achieve the effect of reducing the chip size and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

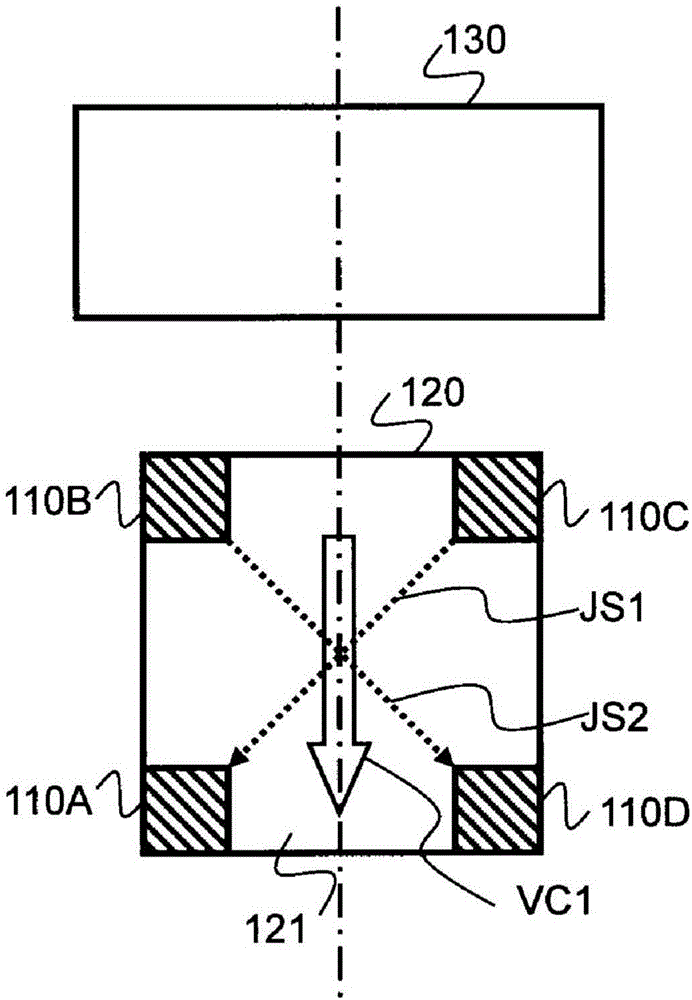

[0053] figure 1It is a plan view showing the Hall sensor of the first embodiment of the present invention. A Hall sensor consists of a Hall element that senses a magnetic field, and a circuit that drives or controls the Hall element.

[0054] First, the shape of the Hall element will be described. Such as figure 1 As shown, the Hall element 120 has a square magnetic induction portion composed of N-type impurity regions 121 and N-type high-concentration impurity regions of the same shape arranged at the vertices of the square magnetic induction portion on the semiconductor substrate. Control current input terminals and Hall voltage output terminals 110A, 110B, 110C, 110D. By making the Hall element 120 of the above-mentioned form, it becomes a symmetrical Hall element.

[0055] Next, the positional relationship between the Hall element and the heat source will be described. A circuit for driving the Hall element 120 is provided on the substrate on which the Hall element ...

Embodiment 2

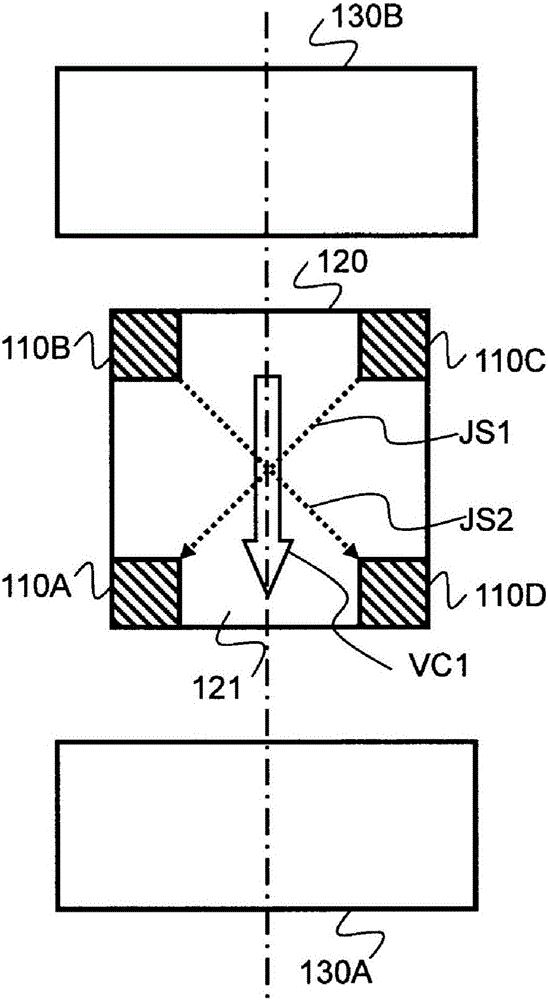

[0072] As a first embodiment, using figure 1 The case where there is one heat source has been described, but the heat generator in the circuit for controlling the Hall element is not limited to one. figure 2 It is a plan view showing the Hall sensor according to the embodiment of the present invention when a plurality of heat generating elements (heat generating sources) 130A, 130B exist in a circuit for controlling the Hall element 120 .

[0073] Even when there are a plurality of heat generating sources, by aligning the center of each heat generating source 130A, 130B on the extension line of the vector sum VC1 of the Hall element control currents JS1 and JS2 in two directions based on the rotating current method, Offset can also be removed.

[0074] Here, the center of the heat source refers to the highest temperature point or region at the peak of the isotherm when the heat source is viewed from above and an isotherm representing a temperature gradient is drawn.

[007...

Embodiment 3

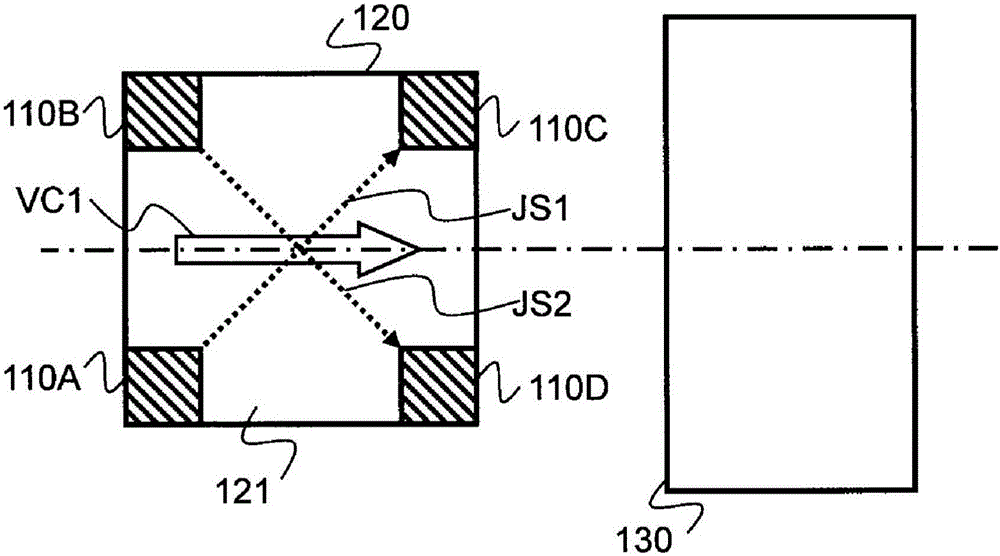

[0077] In addition, as in image 3 shown need to be in with figure 1 and figure 2 When the heat source is arranged in the vertical direction, the Hall element control currents JS1 and JS2 can be controlled by aligning the center of the heat source 130 with the vector of the Hall element control current JS1 and JS2 and the extension line of VC1. to optimize the direction of the , so that the offset can be removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com