Bionic type onion harvesting device

A harvesting device and bionic technology, which is applied in digging harvesters, harvesters, topping machines, etc., can solve the problems that are not suitable for small-area planting users, less research on onion harvesting machines, and increase the cost of onion planting. The effects of working efficiency, simple structure, easy adjustment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments given by the accompanying drawings.

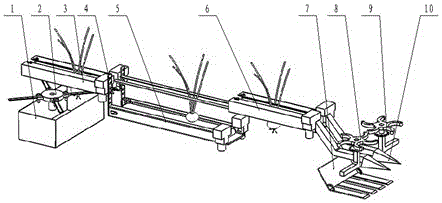

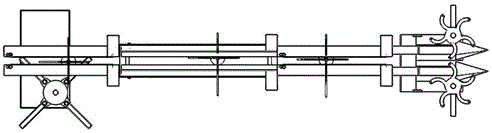

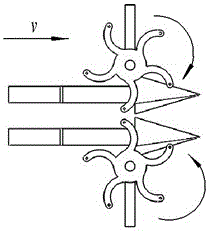

[0020] refer to figure 1 , figure 2 , a bionic onion harvesting device, comprising a loosening device 7, a leaf separating device 10, a leaf pulling device, a front clamping and conveying device 6, an onion tidying device 5, a height adjusting device 4, a rear clamping and conveying device 3, Cutting device 2 and shallot collecting device 1 are characterized in that: described loosening device 7 is made up of plate-type subsoiling shovel, and this device is arranged on the rear and lower part of leaf separating device 10; Described leaf separating device 10 is composed of a pair of leaf separating The device and the pillar used to connect with the front clamping and conveying device 6, the device is placed at the forefront of the onion harvesting device; the leaf blade device is composed of a pair of blade wheel 8 and a sprocket whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com