Single-line maize harvesting machine

A corn harvester, single-row technology, applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of complex operation, heavy harvester, low grain breakage rate, etc., to increase the opening area, solve bulky, The effect of low grain breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

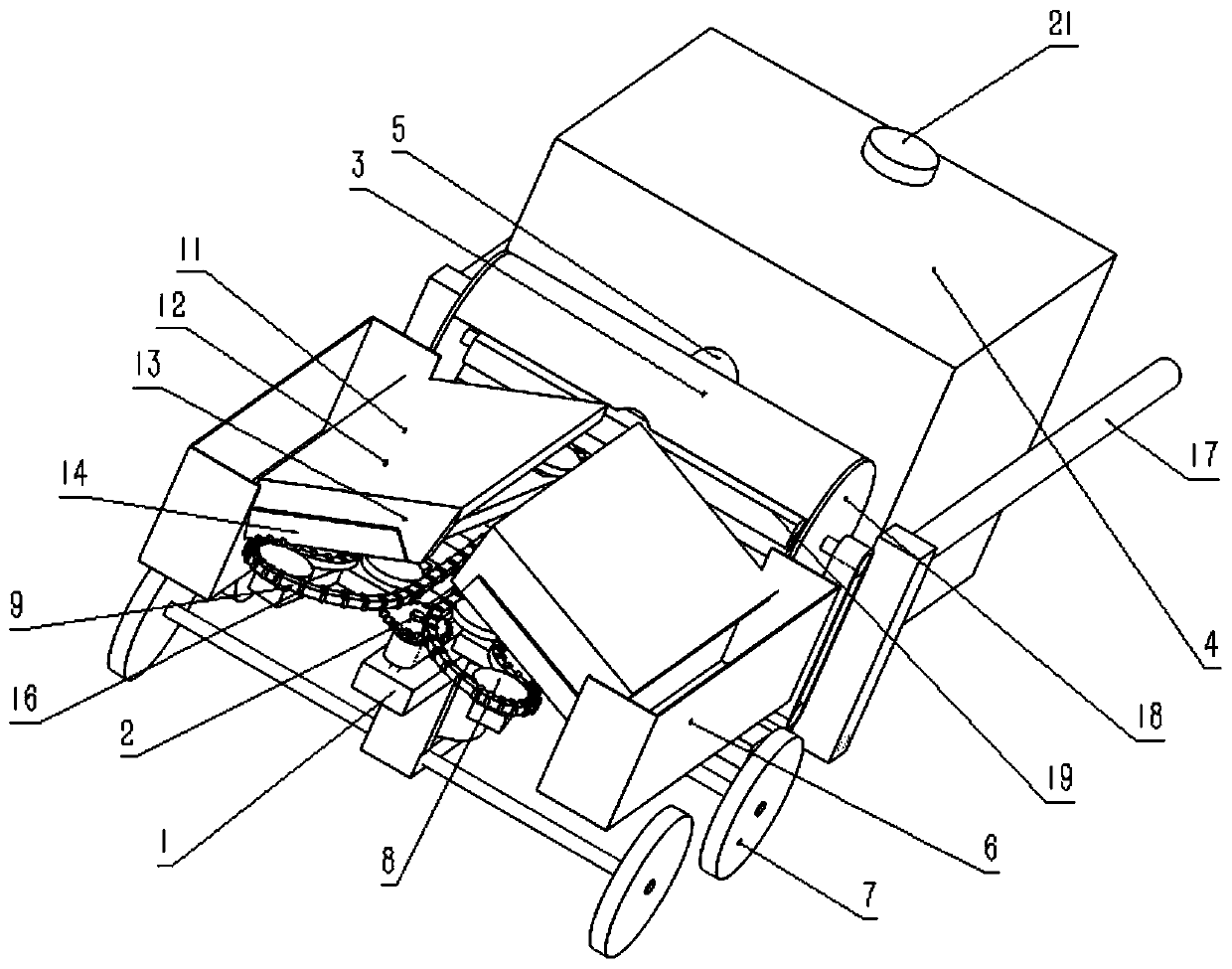

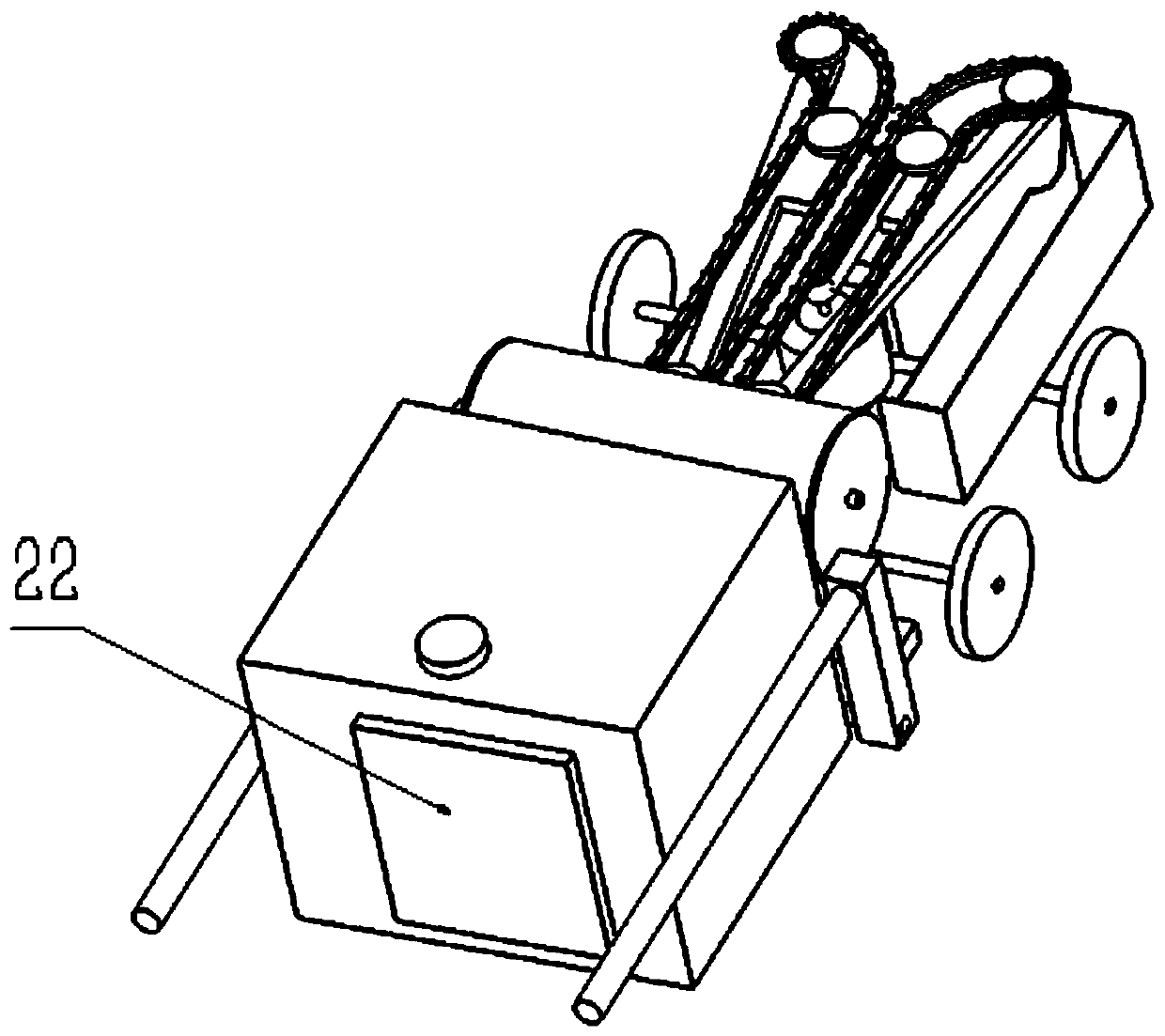

[0028] A single-row corn harvester, comprising a frame 1 and a drum-type hay cutter 3, the frame 1 is provided with a figure-eight-shaped grain guide, the front end of the grain guide extends out of the frame 1, and the machine The frame 1 is provided with a cutter disk 2 directly below the middle part of the grass guide, and the rear end of the grass guide is facing the inlet end of the drum-type hay cutter 3, and the rear end of the drum-type hay cutter 3 passes through the The conveying pipe 5 communicates with the material collection box 4, and the drum-type hay cutter 3 is provided with a feeding fan, and the frame is also provided with a V-shaped ear-picking knife and fork above the grain guide, and the V-shaped ear-picking knife and fork Ear collecting boxes 6 are arranged on both sides, and rolling wheels 7 are arranged under the frame 1 .

[0029] In the present invention, when corn is harvested, the harvester advances, and the middle part of the eight-shaped grain gu...

Embodiment 2

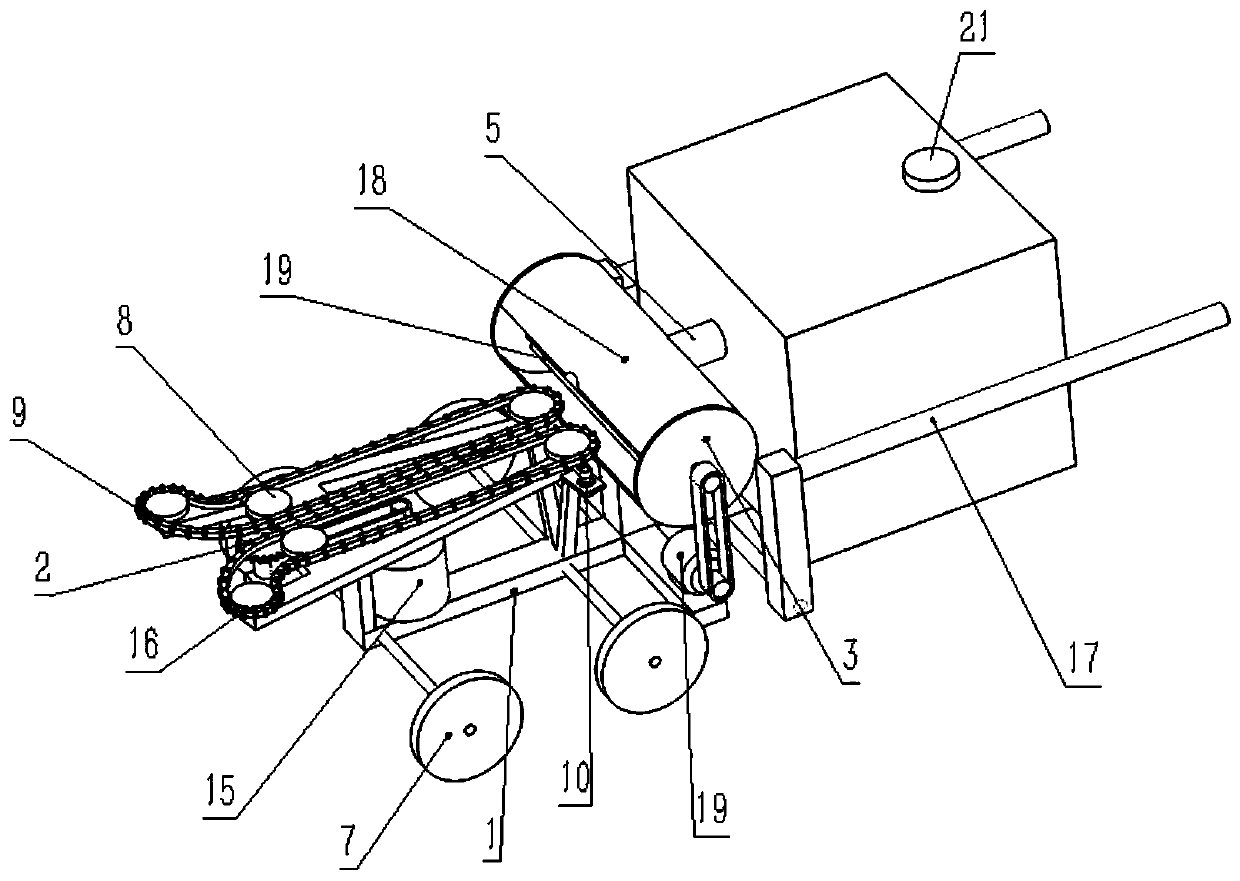

[0031] see figure 1 , a single-row corn harvester, comprising a frame 1, a drum-type hay cutter 3, the frame 1 is provided with a figure-eight-shaped grain guide, the front end of the grain guide extends out of the frame 1, the The frame 1 is provided with a cutter disc 2 directly below the middle part of the grass guide, and the rear end of the grass guide is facing the inlet end of the drum chaff 3, and the rear end of the drum chaff 3 is The material collection box 4 is communicated with the conveying pipe 5, and a feeding fan is provided in the drum-type hay cutter 3, and the frame is also provided with a V-shaped ear picking knife and fork above the grain guide, and the V-shaped ear picking knife is Ear collection boxes 6 are arranged on both sides of the fork, and rolling wheels 7 are arranged under the frame 1 .

[0032] The grain guide includes several grain guide wheels 8 arranged symmetrically on the frame in a figure-eight shape, wherein the outer surfaces of the g...

Embodiment 3

[0037] see figure 1 , a single-row corn harvester, comprising a frame 1, a drum-type hay cutter 3, the frame 1 is provided with a figure-eight-shaped grain guide, the front end of the grain guide extends out of the frame 1, the The frame 1 is provided with a cutter disc 2 directly below the middle part of the grass guide, and the rear end of the grass guide is facing the inlet end of the drum chaff 3, and the rear end of the drum chaff 3 is The material collection box 4 is communicated with the conveying pipe 5, and a feeding fan is provided in the drum-type hay cutter 3, and the frame is also provided with a V-shaped ear picking knife and fork above the grain guide, and the V-shaped ear picking knife is Ear collection boxes 6 are arranged on both sides of the fork, and rolling wheels 7 are arranged under the frame 1 .

[0038] The grain guide includes several grain guide wheels 8 arranged symmetrically on the frame in a figure-eight shape, wherein the outer surfaces of the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com