Air-cooled permanent-magnet coupler and method for cooling the same

A permanent magnet coupler, air-cooled technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, cooling/ventilation device, etc. Advanced problems, to ensure reliable operation, improve efficiency and degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

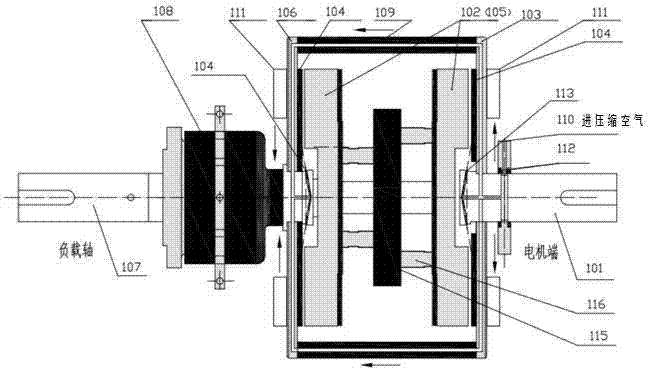

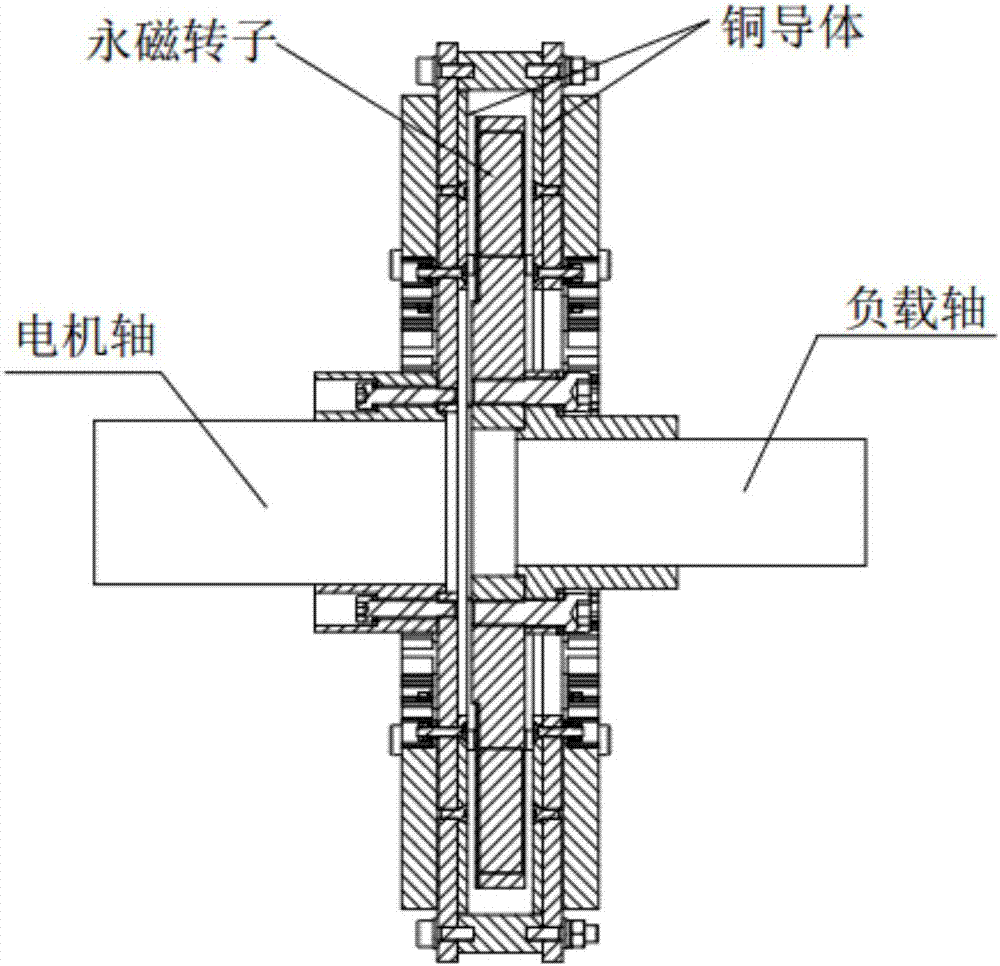

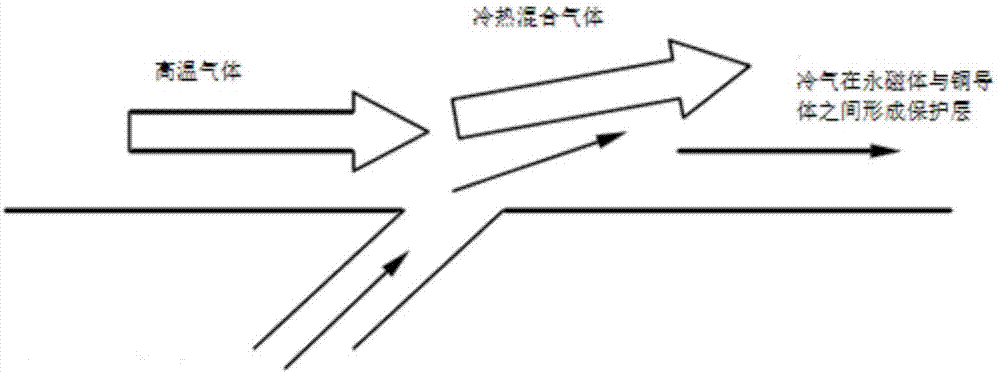

[0049] In order to improve the efficiency and degree of cooling and ensure the reliable operation of the permanent magnetic coupler, especially for the high-power permanent magnetic coupler, the embodiment of the present invention adopts the air film technology, and the copper conductor and the copper conductor in the air-cooled permanent magnetic coupler An insulating air film is formed between the permanent magnet rotors to cool the copper conductors and the permanent magnet rotors while insulating the heat transfer between the copper conductors and the permanent magnet rotors.

[0050] Since the air-cooled permanent magnetic coupler using this air film technology can greatly reduce the operating temperature, its working power can be increased, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com