Kneading fan for paper mulberry silage direct-harvest bundling machine

A technology of baler and silage, which is applied in packaging, application, agricultural machinery and implements, etc., can solve the problems of inconvenient operation, increase the volume and cost of the whole set of equipment, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

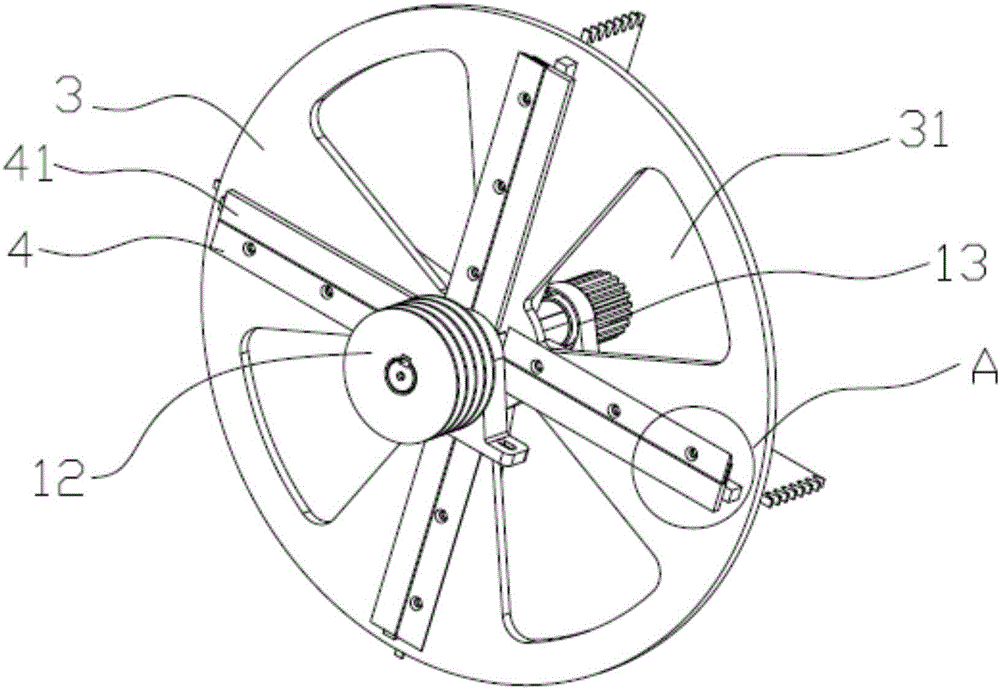

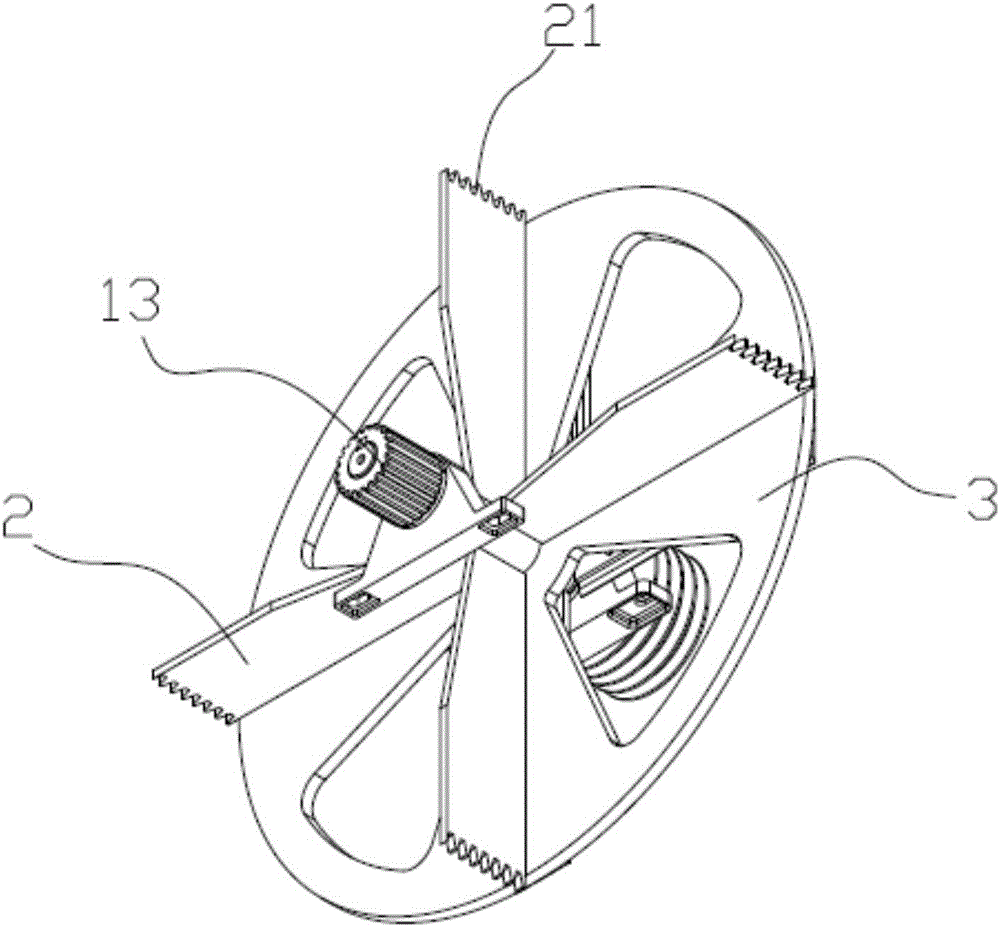

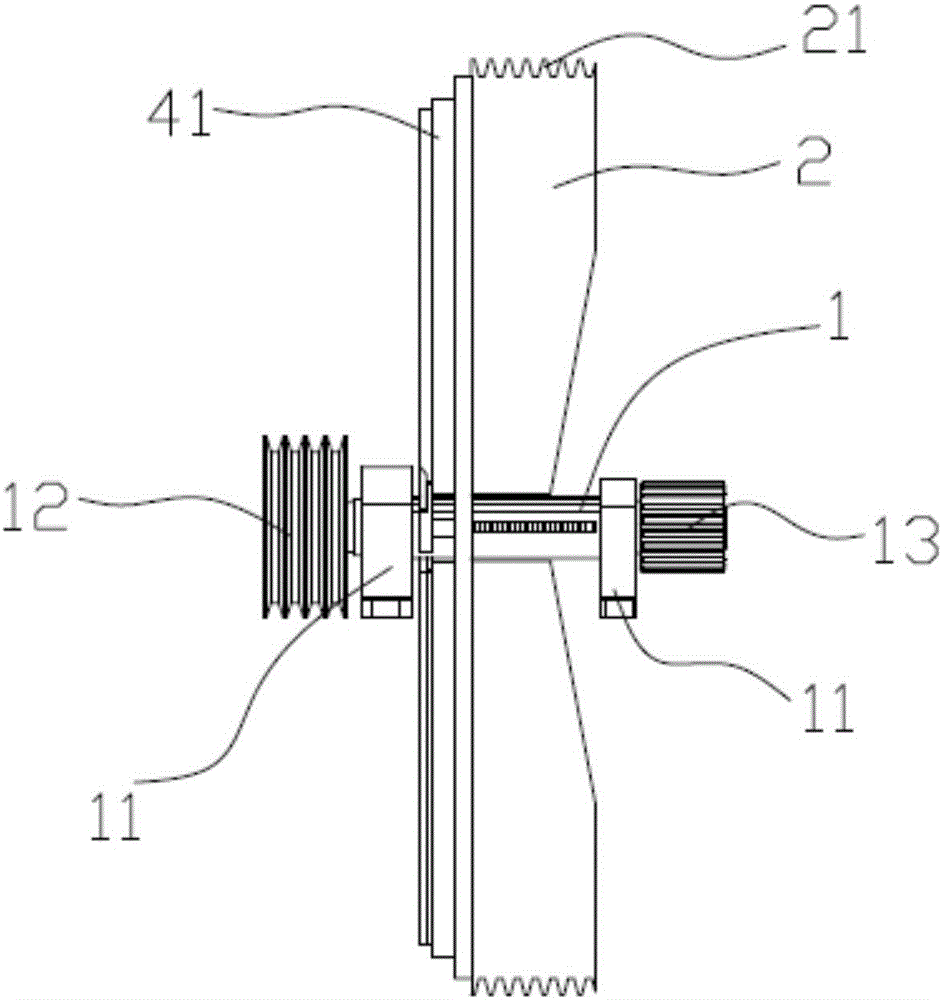

[0020] Combine below Figure 1-Figure 4 Specific embodiments of the present invention are described in detail:

[0021] The present invention includes a rotating shaft 1 and a fan blade 2 , a cutter head 3 and a cutting knife 4 coaxially fixedly connected through the rotating shaft 1 . The fan blade 2 is located behind the cutter head 3 , and the cutting knife 4 is located in front of the cutter head 3 . Two ends of the rotating shaft 1 are provided with a bearing seat 11 respectively, and a pulley 12 is arranged at the front end of the rotating shaft 1 . Because the power of the rotating shaft 1 is relatively large, a transmission gear 13 is arranged at the end of the rotating shaft 1 in this solution. The transmission gear 13 is used to drive other components, saving space and cost. The rotating shaft 1 is driven by the belt pulley 12, and the rotating shaft 1 drives the fan blade 2, the cutter head 3 and the cutting knife 4 to rotate at high speed simultaneously.

[0022...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap