Round silage bale bundling machine

A baler and round baler technology, which is applied in the field of silage round baler, can solve the problems of increased machine cost, high input cost, loud noise, etc., and achieve the advantages of convenient transportation and storage, improved work efficiency, and increased working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

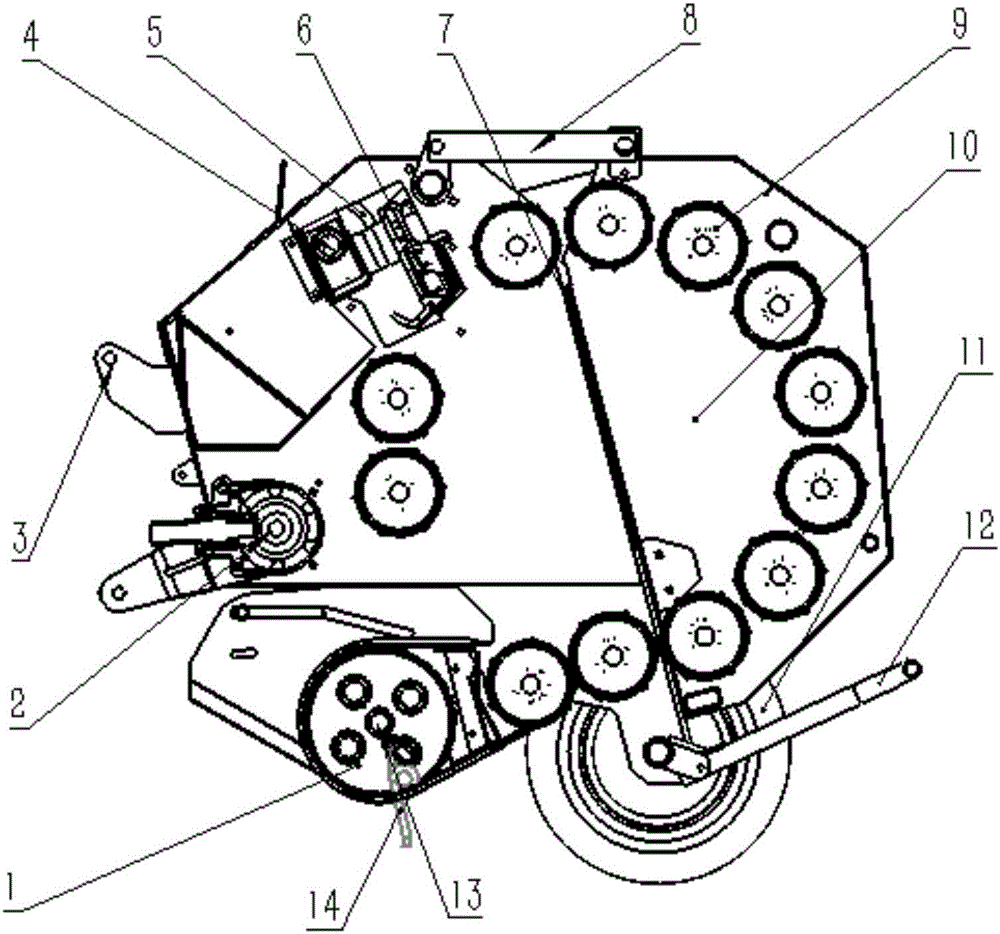

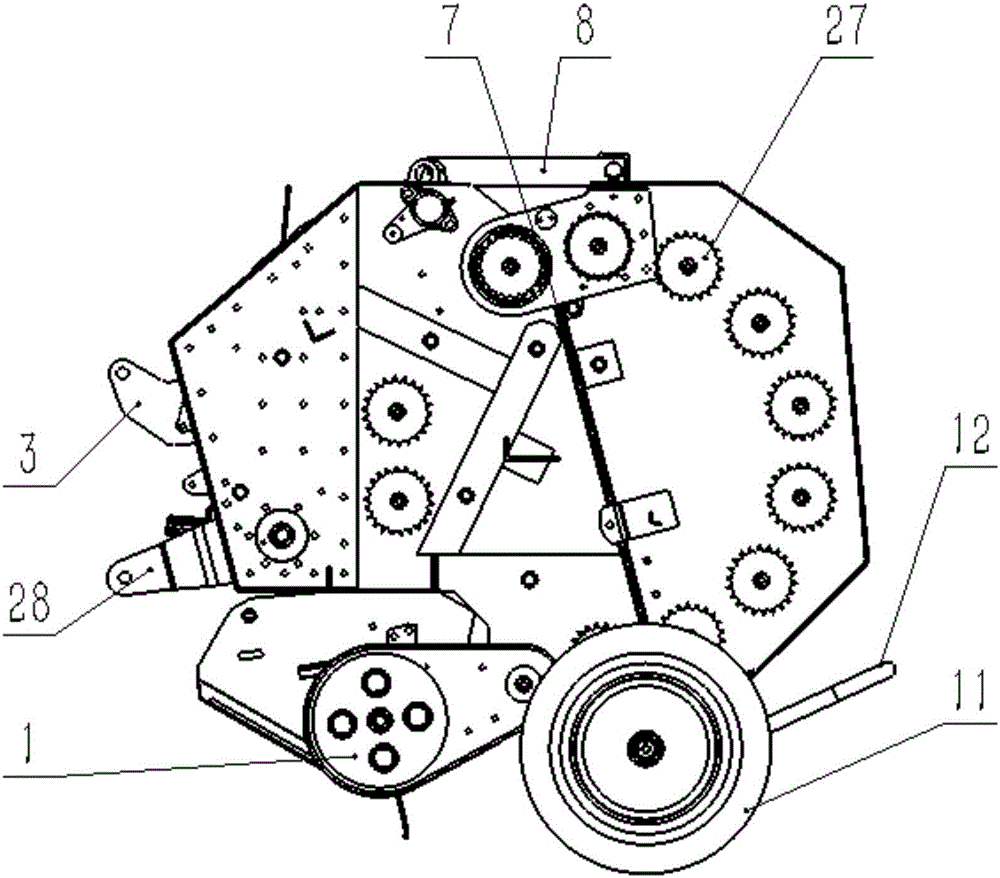

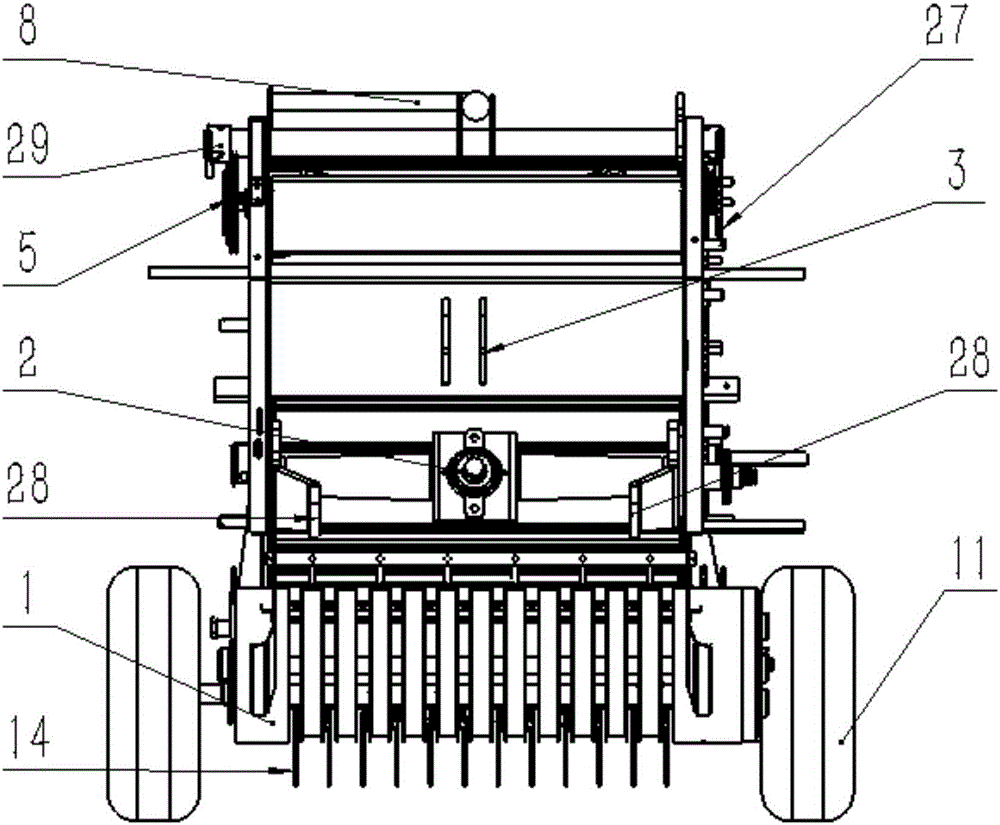

[0028] According to attached Figure 1-7 The present invention is further described:

[0029] A round silage baler is mainly composed of a frame 7, a picker 1, a baling chamber 10, and a baling device 12. figure 1 shown.

[0030] Such as figure 1 Shown is a cutaway view of the baler. Described frame comprises strapping machine skeleton (front frame 22 and rear frame 21), ground wheel 11, suspension mechanism 3, power box 2, pivot crank 29 and rope-releasing mechanism 5; Described strapping machine skeleton is The frame of the whole structure of the machine, the baler skeleton is divided into a front frame 22 and a rear frame 21; the ground wheel 11 is installed under the front frame 22 to realize the walking of the machine; the suspension mechanism 3 is located at the baler The front of the front frame 22 can realize that the whole machine of the baler is suspended on the existing tractor or silage machine; the power box 2 is arranged under the suspension mechanism 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com