Shoe sole of road bike lock shoe and production method thereof

A technology for bicycle locks and manufacturing methods, applied to soles, footwear, footwear, etc., can solve problems such as foot fatigue and stiffness, sole discomfort, physical exertion, etc., achieve comfortable shock-absorbing functions, reduce sports injuries, eliminate The effect of momentary impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

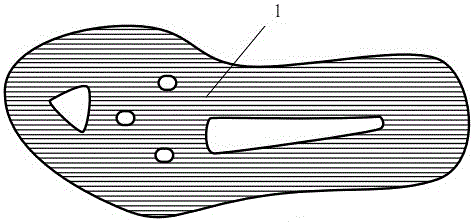

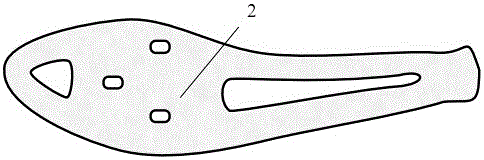

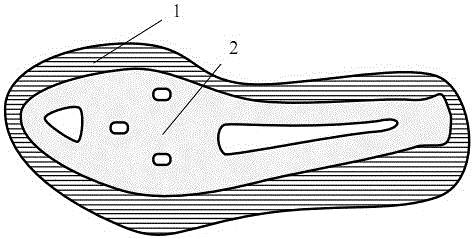

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the road bicycle lock shoe sole described in this embodiment includes a carbon fiber yarn 1 containing epoxy resin and a PU2 layer, and multiple layers of carbon fiber yarn 1 containing epoxy resin are respectively arranged on the upper and lower surfaces of the PU2 layer. , The three are compounded to obtain the sole 3, in which the mass of epoxy resin accounts for 46% of the total mass of carbon fiber yarn 1 and epoxy resin.

Embodiment 2

[0023] The road bicycle lock shoe sole described in this embodiment includes a carbon fiber yarn 1 containing epoxy resin and a PU2 layer. On the upper and lower surfaces of the PU2 layer, several layers of carbon fiber yarn 1 containing epoxy resin are respectively provided. The composite molding obtains the sole 3, in which the mass of the epoxy resin accounts for 30% of the total mass of the carbon fiber yarn 1 and the epoxy resin.

Embodiment 3

[0025] The road bicycle lock shoe sole described in this embodiment includes a carbon fiber yarn 1 containing epoxy resin and a PU2 layer. On the upper and lower surfaces of the PU2 layer, several layers of carbon fiber yarn 1 containing epoxy resin are respectively provided. The composite molding obtains the sole 3, in which the mass of the epoxy resin accounts for 38% of the total mass of the carbon fiber yarn 1 and the epoxy resin.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap