Shoe sole of mountain bicycle lock shoe and method for manufacturing shoe sole

A technology for mountain bikes and manufacturing methods, applied to shoe soles, chemical instruments and methods, insoles, etc., can solve problems such as foot fatigue and stiffness, plantar discomfort, foot discomfort, etc., achieve lasting comfort and reduce sports injuries , making simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

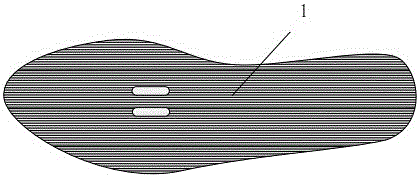

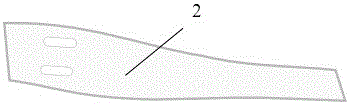

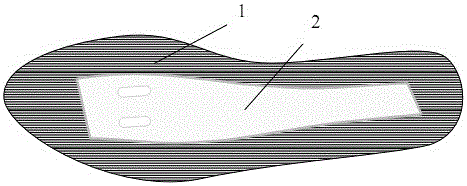

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, a kind of mountain bike lock shoe sole described in this embodiment, it comprises the glass fiber 1 yarn that contains epoxy resin, the carbon fiber yarn that contains epoxy resin and PE foam layer 2, lays a layer that contains ring at the bottom Carbon fiber yarn of epoxy resin, two layers of glass fiber yarn containing epoxy resin are laid on the carbon fiber yarn containing epoxy resin, PE foam layer 2 is arranged on the glass fiber yarn containing epoxy resin, and PE foam Four layers of glass fiber 1 yarn containing epoxy resin are laid on the layer 2;

[0026] Among them, the content of epoxy resin on glass fiber 1 yarn accounts for 20% of the total mass of epoxy resin and glass fiber 1 yarn; the content of epoxy resin on carbon fiber yarn accounts for 30% of the total mass of epoxy resin and carbon fiber yarn.

[0027] The PE foam layer 2 is to paste a layer of non-woven fabric on the uppe...

Embodiment 2

[0029] A kind of mountain bike lock shoe sole described in the present embodiment, it comprises the glass fiber yarn 1 that contains epoxy resin, the carbon fiber yarn that contains epoxy resin and PE foam layer 2, lays two layers of epoxy resin containing at the bottom Carbon fiber yarn, a layer of glass fiber yarn containing epoxy resin is laid on the carbon fiber yarn containing epoxy resin, PE foam layer 2 is arranged on the glass fiber yarn containing epoxy resin, and on the PE foam layer 2 Then lay four layers of glass fiber yarns containing epoxy resin;

[0030] Among them, the content of epoxy resin on glass fiber yarn accounts for 36% of the total mass of epoxy resin and glass fiber yarn; the content of epoxy resin on carbon fiber yarn accounts for 46% of the total mass of epoxy resin and carbon fiber yarn.

[0031] The PE foam layer 2 is to paste a layer of non-woven fabric on the upper and lower surfaces of the PE foam cotton, and paint a layer of resin, acetone and...

Embodiment 3

[0033] A kind of mountain bike lock shoe sole described in this embodiment, it comprises the glass fiber 1 yarn that contains epoxy resin, the carbon fiber yarn that contains epoxy resin and PE foaming layer 2, lays one deck that contains epoxy resin at the bottom Carbon fiber yarn, three layers of glass fiber yarn containing epoxy resin are laid on the carbon fiber yarn containing epoxy resin, PE foam layer 2 is arranged on the glass fiber yarn containing epoxy resin, and on the PE foam layer 2 Then lay four layers of glass fiber yarns containing epoxy resin;

[0034] Among them, the content of epoxy resin on glass fiber 1 yarn accounts for 28% of the total mass of epoxy resin and glass fiber 1 yarn; the content of epoxy resin on carbon fiber yarn accounts for 38% of the total mass of epoxy resin and carbon fiber yarn.

[0035] The PE foam layer 2 is to paste a layer of non-woven fabric on the upper and lower surfaces of the PE foam cotton, and paint a layer of resin, acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap