Automatic vegetable and salad selling cabinet with LED growing and maintaining system inside

A maintenance system and technology of sales cabinets, which are applied to store counters, similar counters, coin-free or similar appliances, etc., can solve the problem of vegetable sales cabinets lacking in primary processing capacity, difficult to guarantee the freshness of commodities, and inability to provide vegetable sales cabinets, etc. problem, to achieve the effect of good sterilization effect, removal of impurities, and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

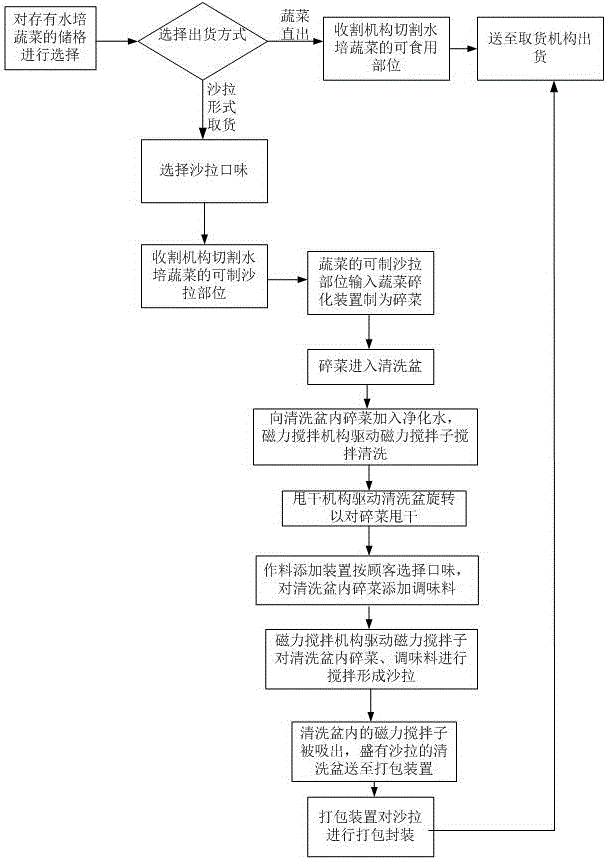

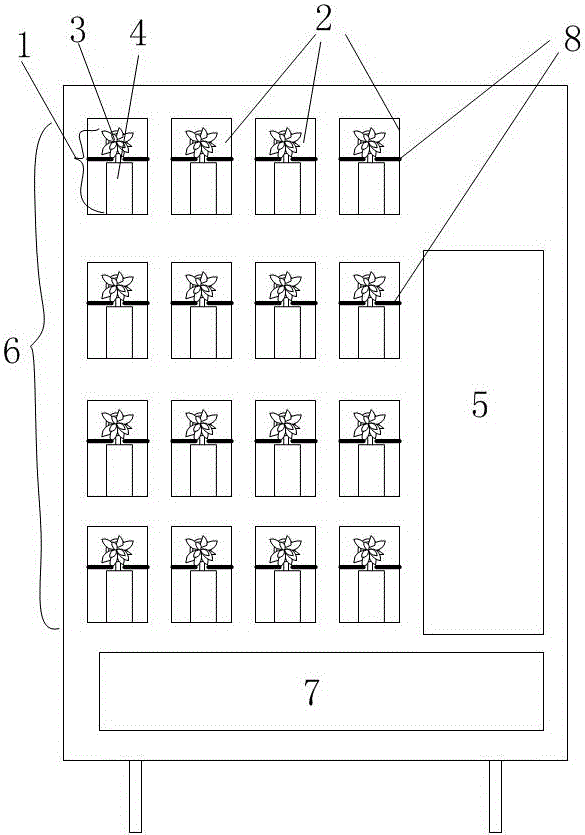

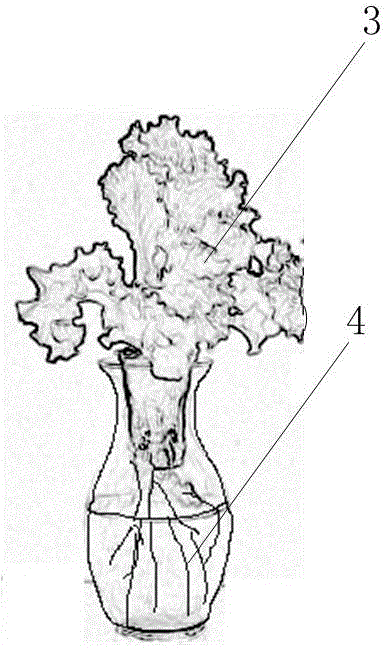

[0045] Such as Figure 1-7 As shown, the vegetable and salad automatic vending cabinet with built-in LED growth and maintenance system is used for the sale of bottled hydroponic vegetables, or the raw materials of bottled hydroponic vegetables in the cabinet are processed into vegetable salads and then sold. The vending cabinet includes containers, Vegetable maintenance array 6, a salad processing mechanism, a water treatment mechanism and a control module; the vegetable maintenance array 6 is arranged on the front of the container, the salad processing mechanism is arranged inside the container, and a pick-up mechanism 7 is provided at the bottom of the container, and the vegetable maintenance array 6 1. The salad processing mechanism is connected with the picking mechanism 7; the water treatment mechanism is connected with the salad processing mechanism.

[0046] The vegetable maintenance array 6 is composed of several vegetable maintenance units 1. The vegetable maintenance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com