A system and method for condensing and thermally rectifying gaseous fractions at the top of the tower

An overhead gas and fraction technology, which is applied in the field of rectification and energy saving, can solve the problems of safety, large energy consumption, large consumption, etc., and achieves the effect of wide usability and energy reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

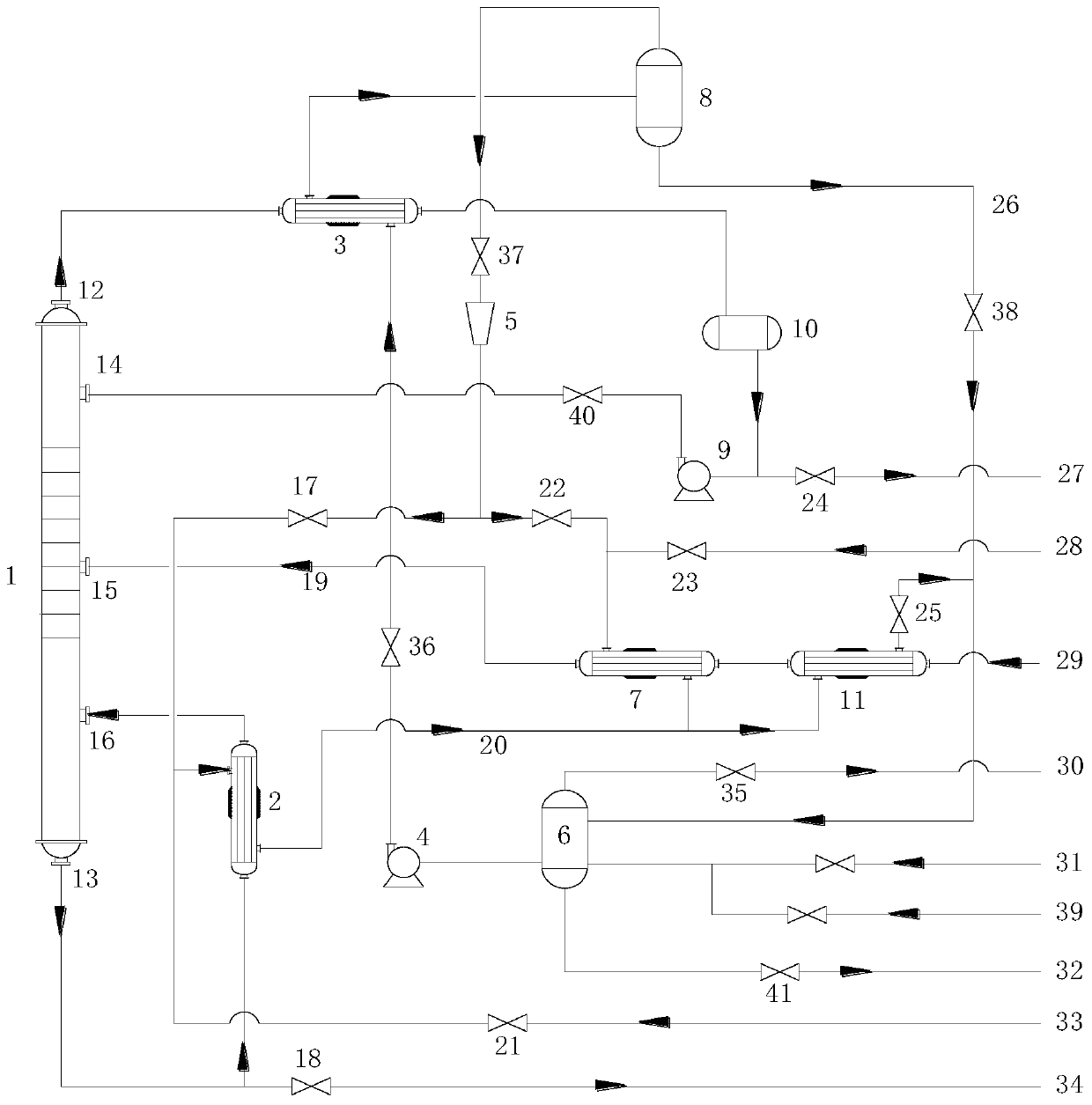

[0049] In the atmospheric rectification system where the raw material is 25°C and 90% by mass methanol aqueous solution, the vapor phase distilled from the top of rectification tower 1 is methanol vapor at 66.9°C and 99% by mass, and the bottom of the tower is 90.6°C with 90% by mass 8.3% methanol solution; open the H valve 35, by adjusting the vacuum system, ensure that the pressure in the water storage tank 6 is 26.2kPa, adjust the reasonable water consumption to make the water in the water storage tank 6 pass through the circulating water pump 4 and the I valve 36 Enter the shell-side inlet on the right side of the bottom of the condensing and vaporizing heat exchanger 3, and methanol vapor distilled from the gas phase outlet 12 at the top of the distillation column 1 at 66.9°C and with a mass percentage of 99% enters the tube side at the left end of the condensing and vaporizing heat exchanger 3 Inlet, the water and the 66.9°C, 99% by mass methanol vapor distilled from the ...

Embodiment 2

[0053]In the atmospheric rectification system where the raw material is 25°C and 90% by mass methanol aqueous solution, the vapor phase distilled from the top of rectification tower 1 is methanol vapor at 66.9°C and 99% by mass, and the bottom of the tower is 81°C with 90% by mass 49.5% methanol solution, open the H valve 35, by adjusting the vacuum system, ensure that the pressure in the water storage tank 6 is 26.2kPa, adjust the reasonable water consumption to make the water in the water storage tank 6 pass through the circulating water pump 4 and the I valve 36 Enter the shell-side inlet on the right side of the bottom of the condensing and vaporizing heat exchanger 3, and methanol vapor distilled from the gas phase outlet 12 at the top of the distillation column 1 at 66.9°C and with a mass percentage of 99% enters the tube side at the left end of the condensing and vaporizing heat exchanger 3 Inlet, the water and the 66.9°C, 99% by mass methanol vapor distilled from the to...

Embodiment 3

[0057] In the normal-pressure rectification system where the raw material is 25°C and 90% mass percent ethanol aqueous solution, the gas phase fraction distilled from the top of rectification tower 1 is 80.2°C and 95% mass percent ethanol water vapor, and the bottom of the tower is 86°C, mass percent Percentage of 50.3% ethanol solution, open the H valve 35, by adjusting the vacuum system, ensure that the pressure in the water storage tank 6 is 47.4kPa, adjust the reasonable water consumption, make the water in the water storage tank 6 pass through the circulating water pump 4 and I The valve 36 enters the shell-side inlet on the right side of the bottom of the condensing and vaporizing heat exchanger 3, and the 80.2°C and 95% by mass ethanol water vapor distilled from the gas phase outlet 12 at the top of the rectifying tower 1 enters the condensing and vaporizing heat exchanger 3 At the inlet of the tube at the left end, the water exchanges heat with the 80.2°C, 95% by mass e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com