Preparation method and product of high-efficiency leaching and adsorbing material for Cd contaminated soil and wastes

A technology of polluted soil and adsorption materials, applied in the field of environmental engineering, can solve the problems of high cost of leaching and repair, single adsorption of heavy metals, and inability to remove heavy metals from soil, etc., and achieve the effect of rapid and efficient leaching and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

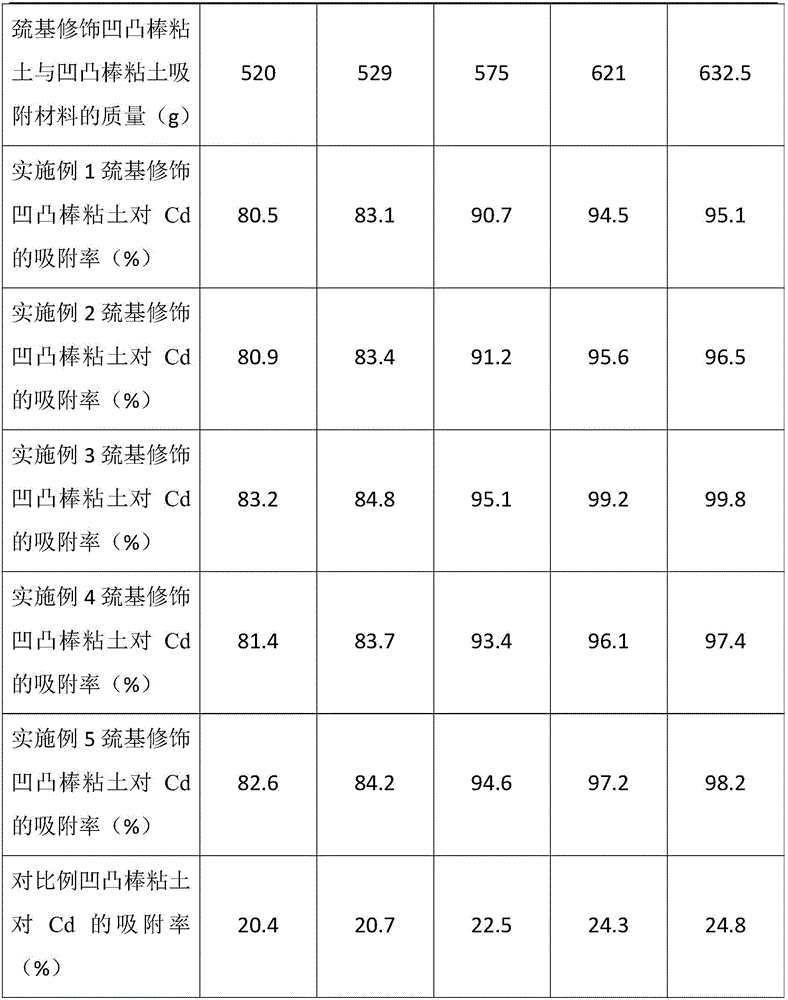

Examples

preparation example Construction

[0022] A method for preparing an efficient leaching adsorption material for Cd-contaminated soil and waste, the steps are:

[0023] (1) Attapulgite clay is dispersed in cetyltrimethylammonium bromide aqueous solution to form attapulgite clay suspension;

[0024] (2) Add ethanol to the attapulgite clay suspension, let it stand for a while to form a mixed solution;

[0025] (3) The mixed solution is placed in a disperser and stirred to become an attapulgite clay colloid;

[0026] (4) Add mercaptopropyltrimethoxysilane to the attapulgite clay colloid, and stir to form a mercapto-modified attapulgite clay gel;

[0027] (5) Air-dry the mercapto-modified attapulgite clay gel, and grind to obtain mercapto-modified attapulgite clay particles.

[0028] In the step (1), the concentration of the cetyltrimethylammonium bromide aqueous solution is 0.5%-2%, and the weight ratio of the cetyltrimethylammonium bromide aqueous solution to the attapulgite clay is 2-4:1.

[0029] The weight ra...

Embodiment 1

[0035] A method for preparing an efficient leaching adsorption material for Cd-contaminated soil and waste, the steps are:

[0036] (1) 450 parts of attapulgite clay are dispersed in 1800 parts of cetyltrimethylammonium bromide aqueous solution (concentration 0.5%) to form attapulgite clay suspension;

[0037] (2) Add 16.1 parts of ethanol to the attapulgite clay suspension, and let it stand for 20 hours to form a mixed solution;

[0038] (3) The mixed solution is placed in a disperser and stirred at a speed of 1500 rpm for 15 minutes to become an attapulgite clay colloid;

[0039] (4) Add 20.5 parts of mercaptopropyltrimethoxysilane to the attapulgite clay colloid under stirring conditions of 500 rpm, and stir for 17 minutes at a speed of 1500 rpm to form a mercapto-modified attapulgite clay gel;

[0040] (5) Air-dry the attapulgite clay gel at 20° C., and grind to obtain mercapto-modified attapulgite clay particles.

Embodiment 2

[0042] A method for preparing an efficient leaching adsorption material for Cd-contaminated soil and waste, the steps are:

[0043] (1) 450 parts of attapulgite clay are dispersed in 1700 parts of cetyltrimethylammonium bromide aqueous solution (concentration 0.7%) to form attapulgite clay suspension;

[0044] (2) Add 17 parts of ethanol to the attapulgite clay suspension, let it stand for 22 hours to form a mixed solution;

[0045] (3) The mixed solution is placed in a disperser and stirred at a speed of 1600 rpm for 14 minutes to become an attapulgite clay colloid;

[0046] (4) Add 22 parts of mercaptopropyltrimethoxysilane to the attapulgite clay colloid at a stirring condition of 700 rpm, and stir at a speed of 1600 rpm for 16 minutes to form a mercapto-modified attapulgite clay gel;

[0047] (5) Air-dry the attapulgite clay gel at 24° C., and grind to obtain mercapto-modified attapulgite clay particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com