A kind of method for preparing catalytic cracking catalyst by ammonia-free method

A catalytic cracking and catalyst technology, which is applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as direct discharge of salty wastewater to pollute the environment, preparation methods that have not been reported, and molecular sieve bed overheating, etc. The effect of reducing the burden of sewage treatment, avoiding the discharge of "three wastes" and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

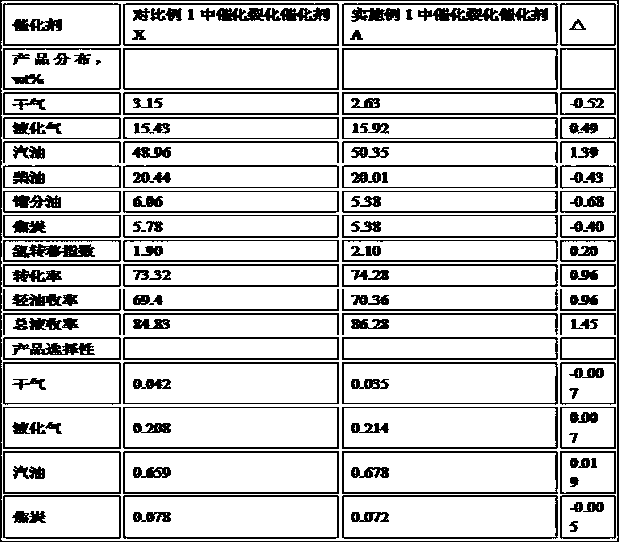

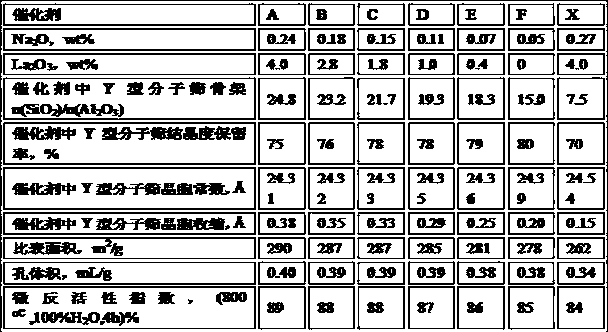

Embodiment 1

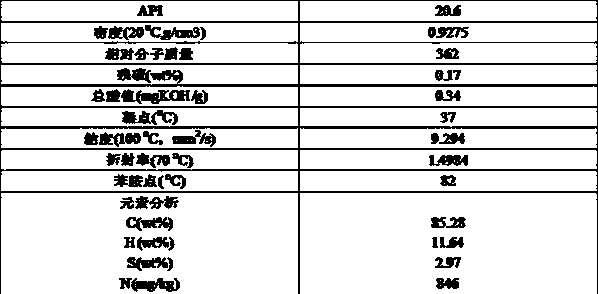

[0101] Embodiment 1: get the NaY molecular sieve former powder slurry (12.6wt% of sodium oxide content, unit cell constant 24.69Å, skeleton n (SiO 2 ) / n(Al 2 o 3 ) is 5.6, crystallinity 95%), according to the NaY molecular sieve former powder of 35wt% and 38wt% kaolin (Suzhou kaolin, alumina content 44.6wt%, sodium oxide+potassium oxide content 0.3wt%, high Ridge stone content 86wt%), 7% weight rare earth oxide, 20wt% composite binder (among them aluminum sol 50wt%; Pseudoboehmite 50wt%, produced by Aluminum Corporation of China Shandong Branch, sodium oxide content 0.3 wt%, specific surface area 280m 2 / g), with deionized water to obtain a solid content of 30% slurry after spray molding, made spray microspheres.

[0102] The obtained spray microspheres were cured at 450° C. for 5 hours to obtain cured microspheres.

[0103] The obtained cured microspheres are cured at high temperature and cooled to 150°C, and then according to the weight ratio of halogen-containing gas mo...

Embodiment 2

[0105] Embodiment 2: get the NaY molecular sieve former powder slurry (11.8wt% of sodium oxide content, unit cell constant 24.67Å, skeleton n (SiO 2 ) / n(Al 2 o 3 ) is 5.4, crystallinity 93%) and NaZSM-5 molecular sieve powder dry powder (sodium oxide content 4.8wt%), according to the molecular sieve powder (wherein NaY accounts for 98.5wt%; NaZSM-5 Accounting for 1.5wt%, 39.5wt% kaolin (Maoming kaolin, alumina content 37.5wt%, sodium oxide + potassium oxide content 0.35wt%, kaolinite content 87wt%), 6% weight rare earth oxide, 21wt% composite Binder (including 48wt% aluminum sol; 52wt% pseudoboehmite, produced by Zibo Shuoren Alumina Technology Co., Ltd., with a sodium oxide content of 0.05wt% and a specific surface area of 320m 2 / g), and deionized water is prepared with deionized water to obtain a slurry with a solid content of 34% and then sprayed to form spray microspheres.

[0106] The obtained spray microspheres were cured at 500° C. for 3.5 hours to obtain cured mi...

Embodiment 3

[0109] Embodiment 3: getting water content is the former powder filter cake of NaY molecular sieve of 25wt% (sodium oxide content 11wt%, unit cell constant 24.66Å, skeleton n (SiO 2 ) / n(Al 2 o 3 ) is 5.4, crystallinity 92%) and NaZSM-5 molecular sieve former powder dry powder (sodium oxide content 4.6wt%), according to the molecular sieve former powder of 32wt% based on catalyst dry basis (wherein NaY accounts for 96wt%; NaZSM-5 accounts for 4wt% %), 41wt% kaolin (Fujian Longyan kaolin, alumina content 45.1wt%, sodium oxide + potassium oxide content 0.55wt%, kaolinite content 82wt%), 5% weight rare earth oxide, 22wt% composite binder (Alumina sol 46wt%; pseudo-boehmite 54wt%, produced by Qingdao Shanke Haitai New Material Co., Ltd., sodium oxide content 0.3wt%, specific surface area 260m 2 / g), with deionized water to obtain a solid content of 38% slurry after spray molding, made spray microspheres.

[0110] The obtained spray microspheres were cured at 550° C. for 3 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com