Labor-saving manually-operated wire rope cutting device

A cutting device and wire rope technology, applied in the field of manual wire rope cutting devices, can solve the problems of increasing the quality of the device, delaying time, labor-intensive danger, etc., and achieve the effects of improving cutting efficiency, saving operating time, and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

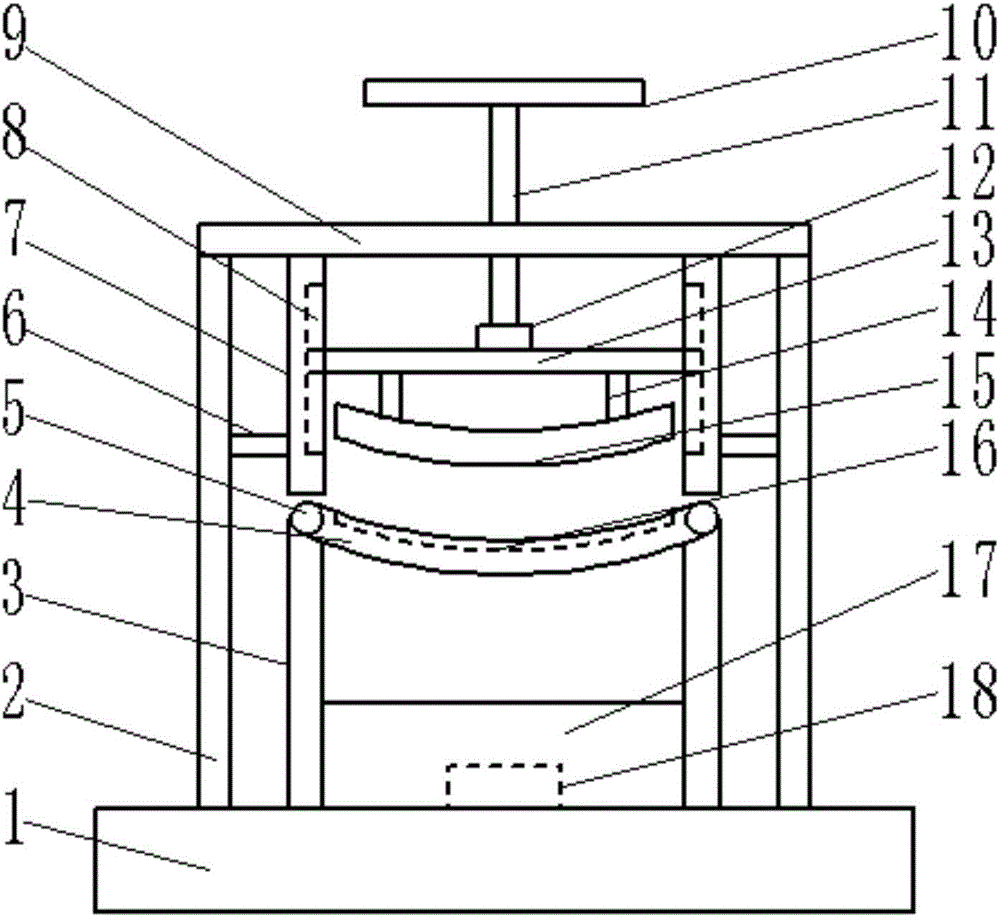

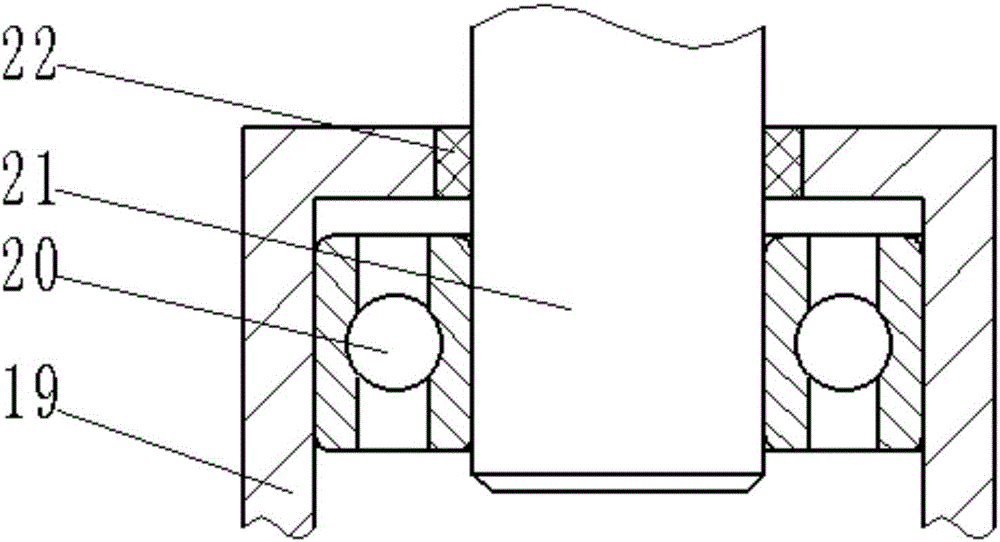

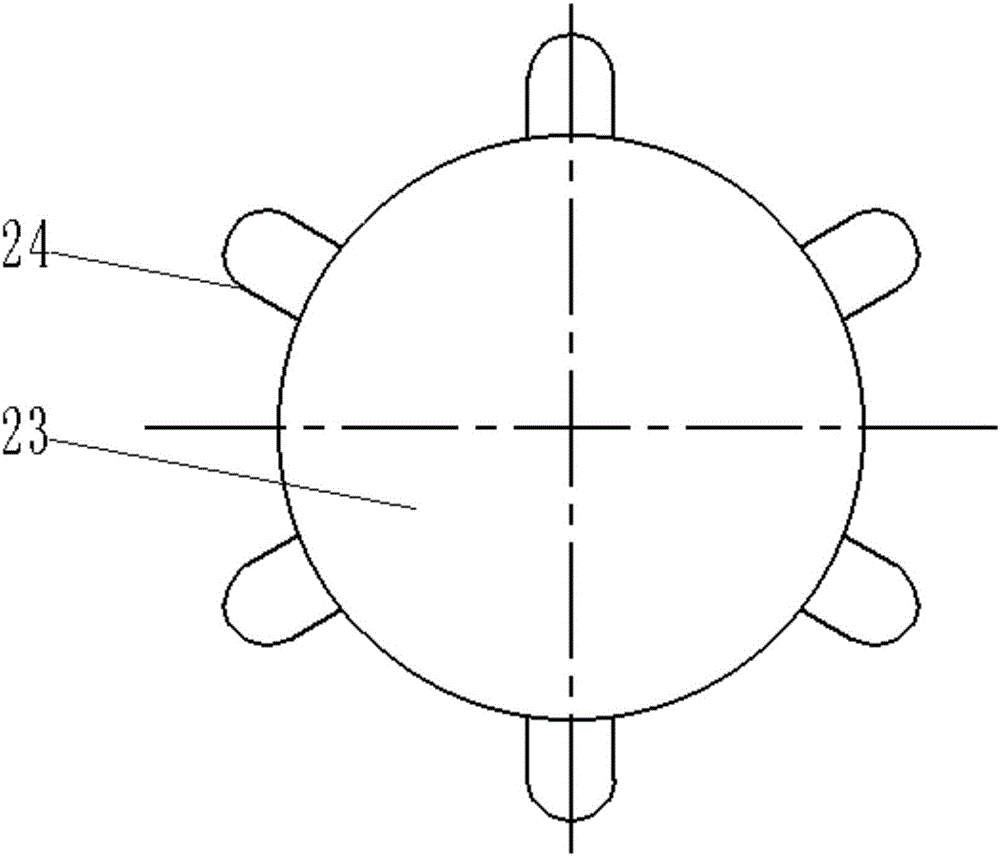

[0017] See Figure 1-3 , A labor-saving manual wire rope cutting device, including a base 1, a support plate 9 and a cutting knife 15. The base 1 is provided with a collection box 17 in the middle, and the collection box 17 is provided with a column 3 on the outside, and a base outside the column 3 1 is provided with a pillar 2; the collection box 17 is fixed on the upper surface of the base 1, and a magnet 18 is placed in the collection box 17 to absorb the filaments scattered during cutting; the pillars 3 are two in total, which are distributed On the left and right sides of the collection box 17, hinges 5 are provided on the top of the column 3, and the column 3 is connected with a support block 4 through the hinge 5; the support block 4 is arranged on the top of the two columns 3, and the shape of the support block 4 is round The top of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com