A non-vacuum melting horizontal continuous casting production process for high-strength and high-conductivity cu-cr-zr alloy rods

A non-vacuum smelting and alloy rod technology, which is applied in the field of preparation of high-performance copper alloys, to achieve the effect of achieving plate weight, improving surface quality, and improving subsequent cold working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

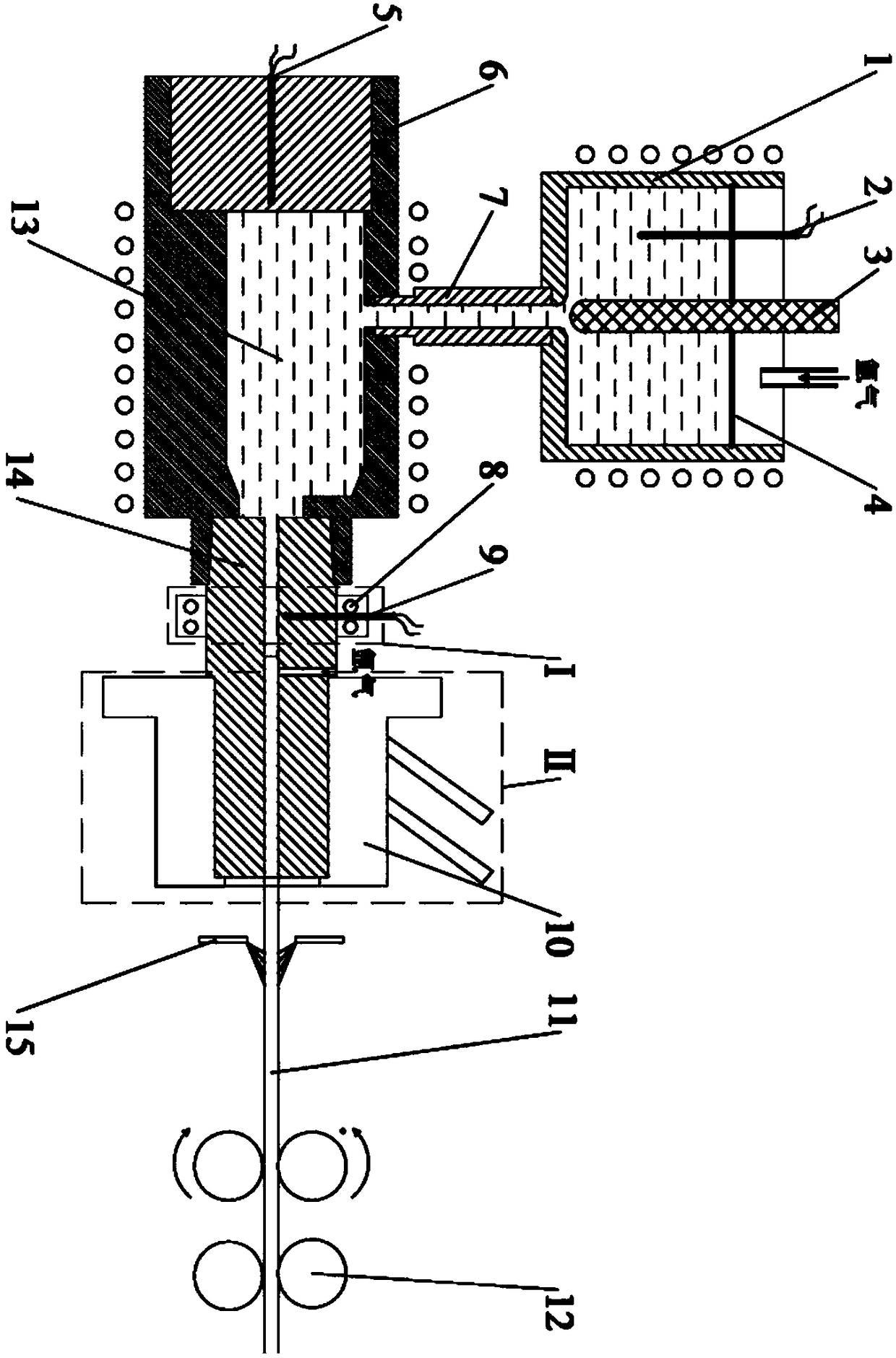

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Continuous casting of Cu-1.0%Cr-0.16%Zr alloy rods with a diameter of Φ30mm

[0029] (1) Add a Cu-Cr-Zr alloy containing 1.0wt% Cr, 0.16wt% Zr, and impurity <0.2wt% into the melting furnace, heat it to 1350°C and melt it, and protect it with argon in the alloy melting and solidification interval;

[0030] (2) Applying Al to the inner surface of the graphite mold2 o 3 coating;

[0031] (3) Start the mold heating device and cooling device, heat the mold heating section to 1300°C, and the cooling water flow rate of the water-cooled crystallizer is 600L / h;

[0032] (4) Lift the stopper, transfer the molten metal through the draft tube into the holding furnace, close the stopper, and the smelting system continues to smelt the Cu-Cr-Zr alloy;

[0033] (5) The temperature of the holding furnace is set to 1300°C, and left to stand for 0.6h;

[0034] (6) Start the horizontal traction mechanism and the water spray secondary cooling device at the mold outlet (water f...

Embodiment 2

[0035] Example 2: Continuous casting of Cu-0.5%Cr-0.08%Zr alloy rod with diameter Φ50mm

[0036] (1) Add the Cu-Cr-Zr alloy containing 0.5wt% Cr, 0.08wt% Zr, and impurity<0.2wt% into the melting furnace, heat to 1300°C for melting, and add covering agent and refining agent;

[0037] (2) Applying Al to the inner surface of the graphite mold 2 o 3 coating;

[0038] (3) Start the mold heating device and cooling device, heat the mold heating section to 1250°C, and the cooling water flow rate of the water-cooled crystallizer is 800L / h;

[0039] (4) Lift the stopper, transfer the molten metal through the draft tube into the holding furnace, close the stopper, and the smelting system continues to smelt the Cu-Cr-Zr alloy;

[0040] (5) The temperature of the holding furnace is set to 1250°C, and it is left to stand for 0.4h;

[0041] (6) Start the horizontal traction mechanism and the water spray secondary cooling device at the mold outlet (water flow rate: 500L / h), and carry out ...

Embodiment 3

[0042] Example 3: Continuous casting of Cu-0.2%Cr-0.04%Zr alloy rods with a diameter of Φ80mm

[0043] (1) Put the Cu-Cr-Zr alloy containing 0.2wt% Cr, 0.04wt% Zr, and impurity<0.2wt% into the melting furnace, heat to 1250°C to melt, add covering agent and refining agent;

[0044] (2) BN coating is applied to the inner surface of the graphite mold;

[0045] (3) Start the mold heating device and cooling device, heat the mold heating section to 1200°C, and the cooling water flow rate of the water-cooled crystallizer is 1000L / h;

[0046] (4) Lift the stopper, transfer the molten metal through the draft tube into the holding furnace, close the stopper, and the smelting system continues to smelt the Cu-Cr-Zr alloy;

[0047] (5) The temperature of the holding furnace is set to 1200°C, and it is left to stand for 0.5h;

[0048] (6) Start the horizontal traction mechanism and the water spray secondary cooling device at the mold outlet (water flow: 800L / h), and carry out continuous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com