Plasma arc cutting torch

A technology of plasma arc and plasma gas, which is applied in the field of arc cutting torches, can solve the problems of easily burnt nozzles, nozzle heating, damage, etc., and achieve the effects of improving heat dissipation, increasing compression density, and reducing high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

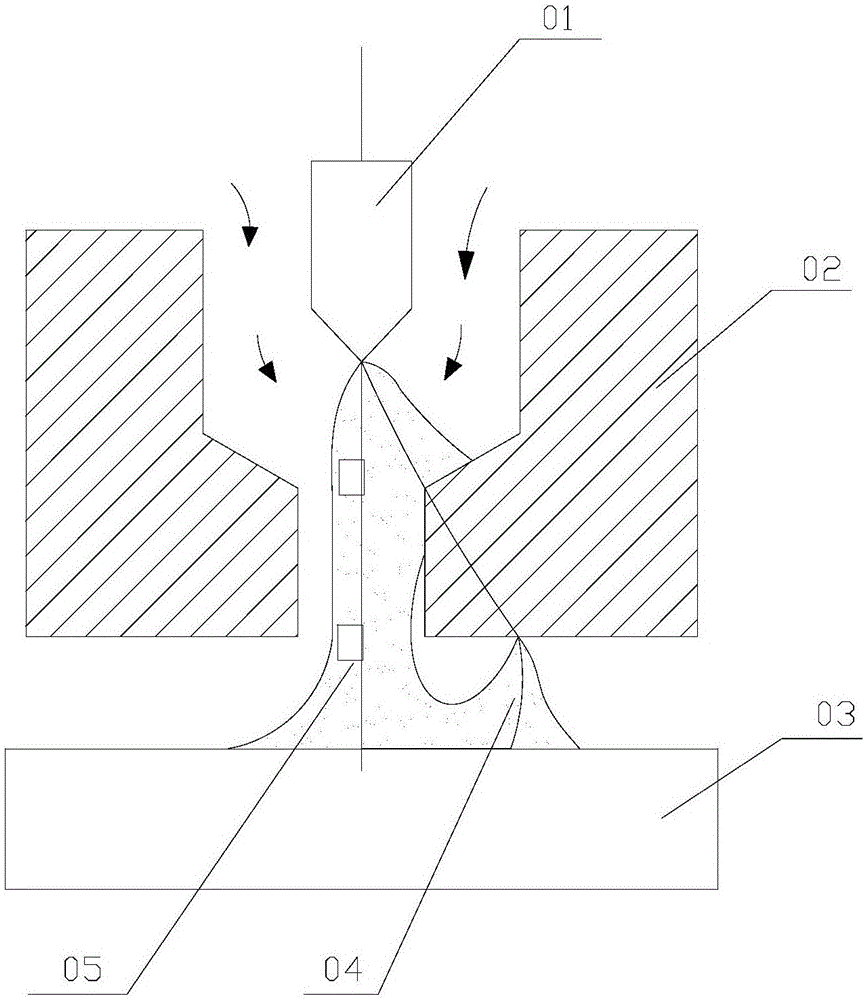

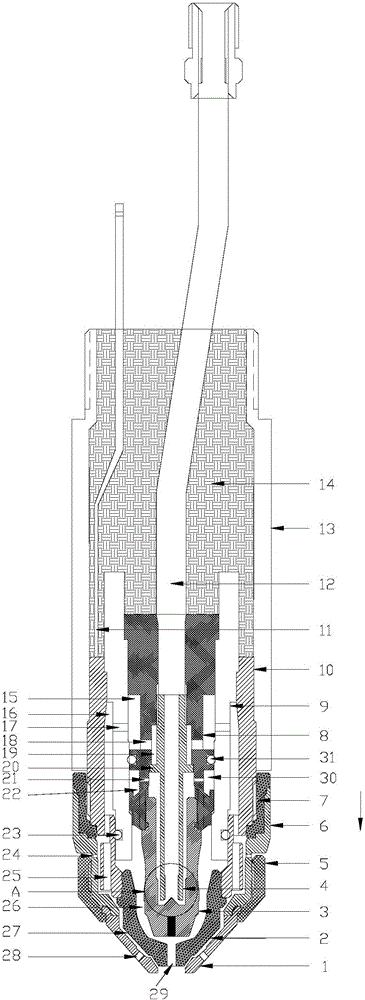

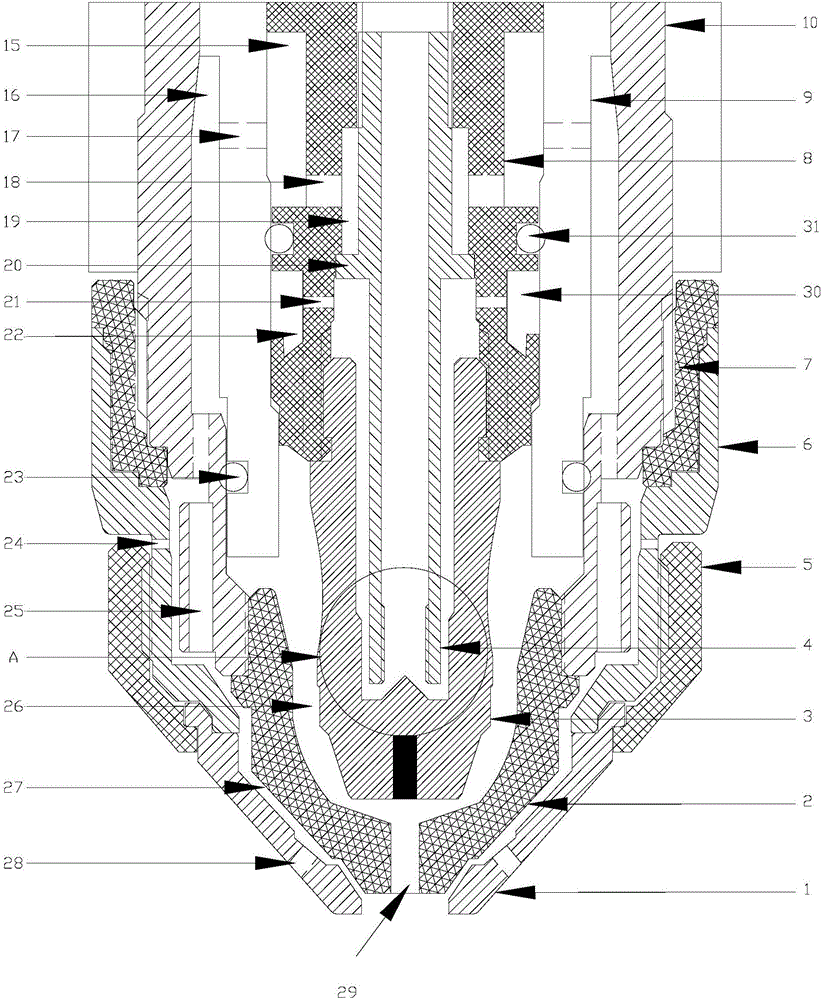

[0037] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0038] Such as Figure 2-5 As shown, a kind of plasma arc cutting torch of the present invention, comprises cutting torch body 13, and the rear portion in described cutting torch body 13 is provided with upper inner insulator 14, and described upper inner insulator 14 is provided with gas pipe 12 and pilot arc The line 11 and the upper inner insulator 14 are made of ceramic materials, which mainly isolate the high-frequency voltage of the spout base 10 and the electrode base 8 of the outer layer. The front portion of the torch body 13 is provided with a spout 2, and the spout 2 is connected to the outer edge of the upper inner insulator 14 through the spout base 10, and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com