A sealing plate blanking device and a bearing sealing plate welding system

A sealing and blanking technology, which is applied to welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of low work efficiency and inability to realize welding automation, and achieve the effects of improving production efficiency, meeting production needs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

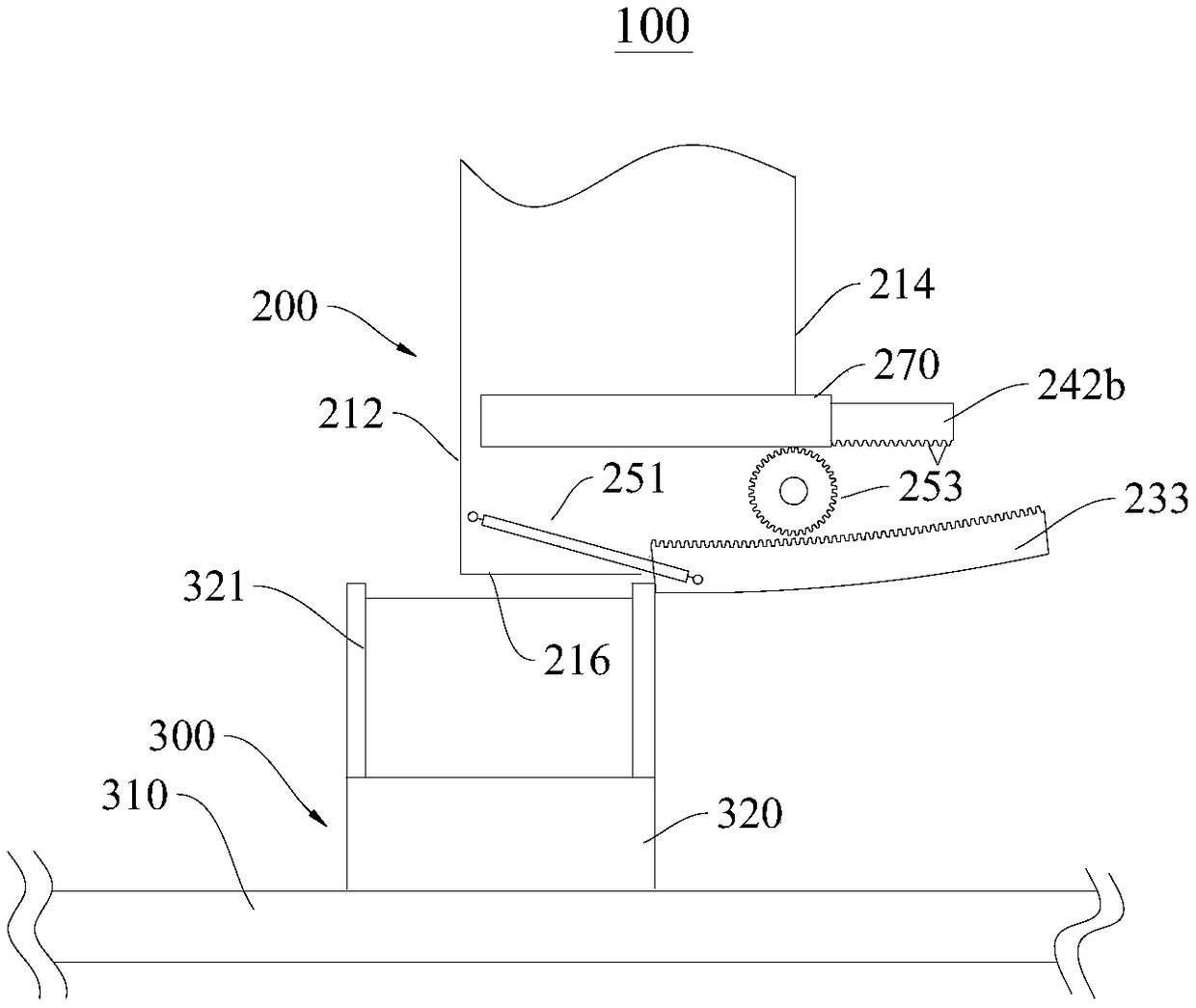

[0039] Please refer to figure 1 and figure 2 , the present embodiment provides a sealing plate blanking system 100 , which includes a sealing plate blanking device 200 and a bearing seat conveying device 300 .

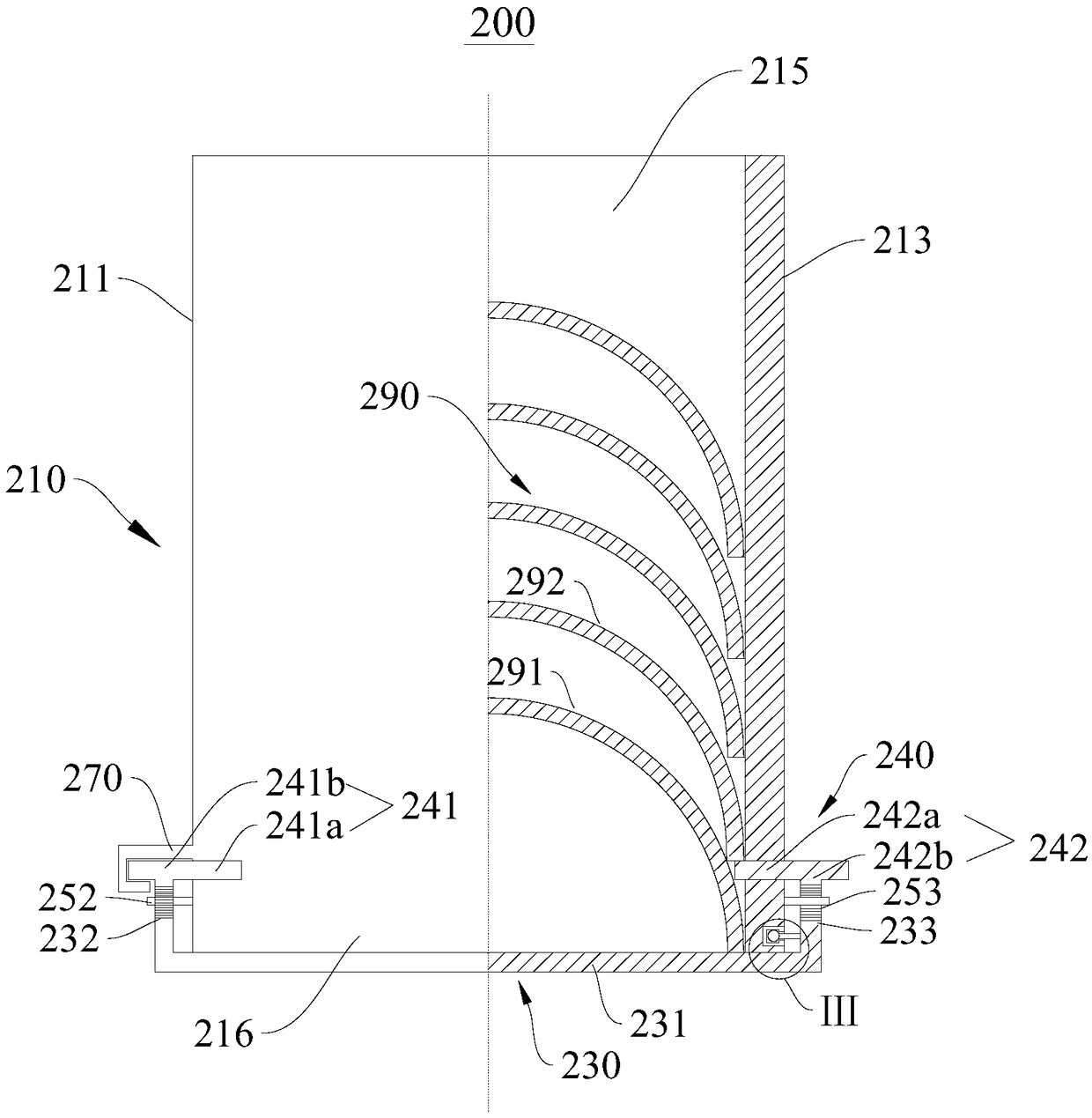

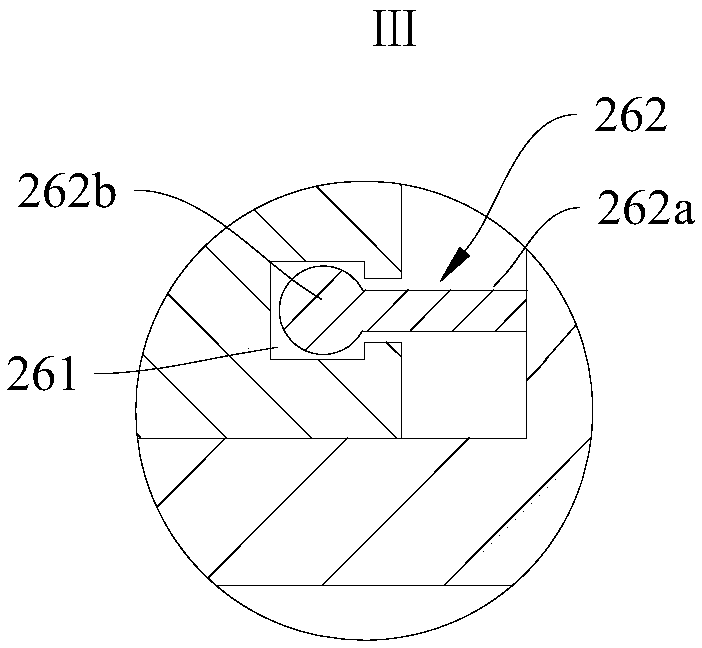

[0040] The sealing board blanking device 200 includes a box body 210 , a bottom plate 230 , a stopper 240 , a first transmission gear 252 , a second transmission gear 253 and a support frame (not shown) for supporting the box body 210 . The box body 210 includes a first side wall 211, a second side wall 212, a third side wall 213 and a fourth side wall 214, the first side wall 211 is opposite to the third side wall 213, the second side wall 212 is connected to the fourth side wall The side walls 214 are oppositely disposed. The first side wall 211, the second side wall 212, the third side wall 213 and the fourth side wall 214 enclose a vertical unloading channel 215 for stacking the sealing plate 290, and the bottom of the box body 210 is provided with a The feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com