Automatic capping machine

A capping and automatic technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low operating efficiency and difficulty in meeting the needs of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

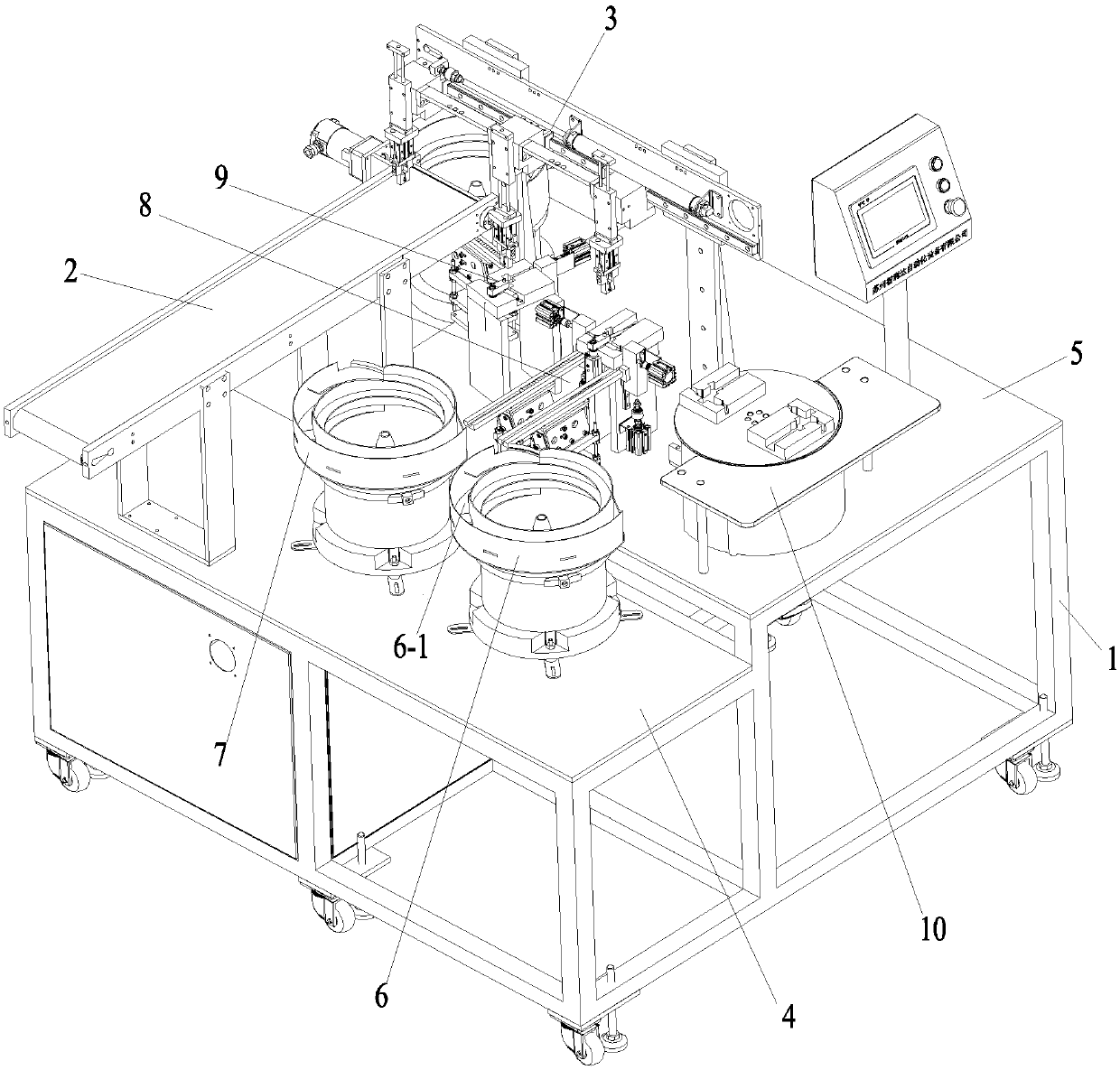

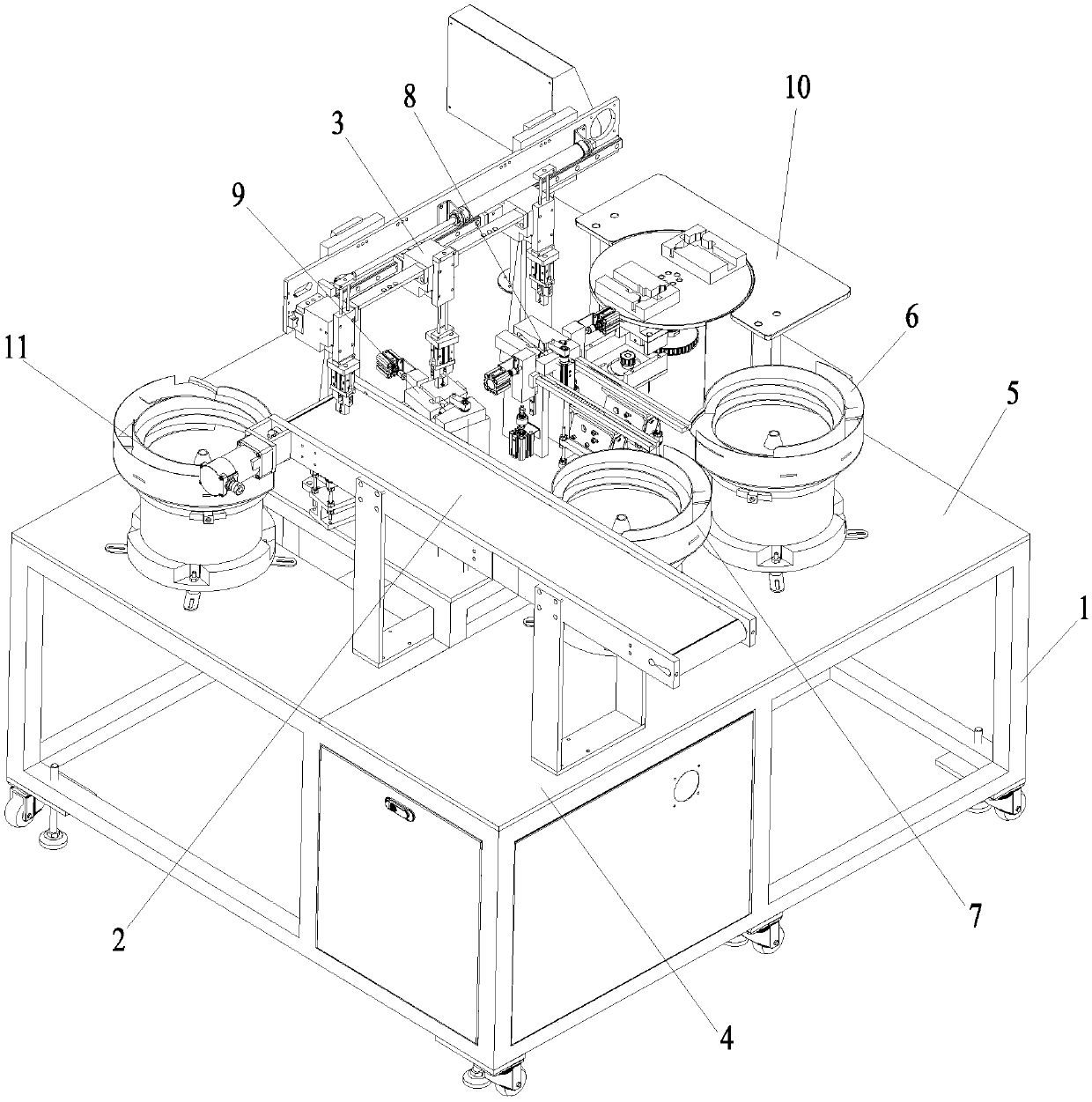

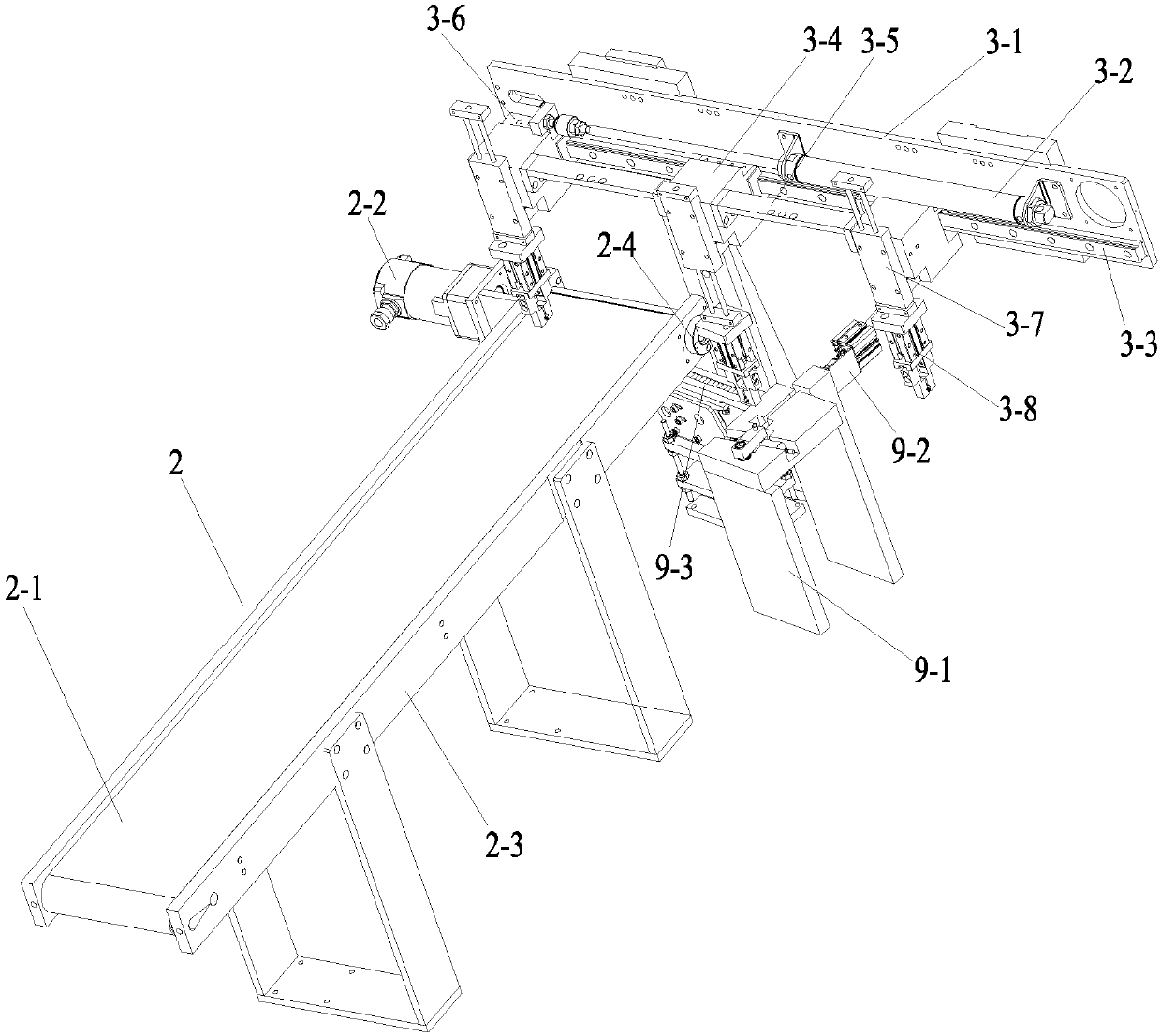

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Figure 1~6 Among them, including support 1, unloading device 2, conveyor belt 2-1, driving motor 2-2, unloading bracket 2-3, conveying roller 2-4, retrieving device 3, retrieving bracket horizontal plate 3-1, Horizontal moving cylinder 3-2, guide rail 3-3, slider 3-4, positioning plate 3-5, in-position pressure head pressing plate 3-6, lifting cylinder 3-7, jaw cylinder 3-8, vibration plate bottom plate 4. Feeding bottom plate 5, first vibrating plate 6, material channel 6-1, second vibrating plate 7, first cap pressing device 8, longitudinal support frame 8-1, I-beam bottom plate 8-2, cap pushing cylinder 8-3, rotary cylinder 8-4, briquetting block 8-5, first track 8-6, connecting plate 8-7, second pressing cap device 9, bracket plate 9-1, pressing cylinder 9-2, the first Two rails 9-3, spare parts device 10, stepping motor 10-1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com