Quick replacement mechanism for screwdriver bits

A technology of batch heads and clamping mechanism, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of low efficiency of batch head replacement, improve production efficiency, overcome manual replacement of batch heads, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

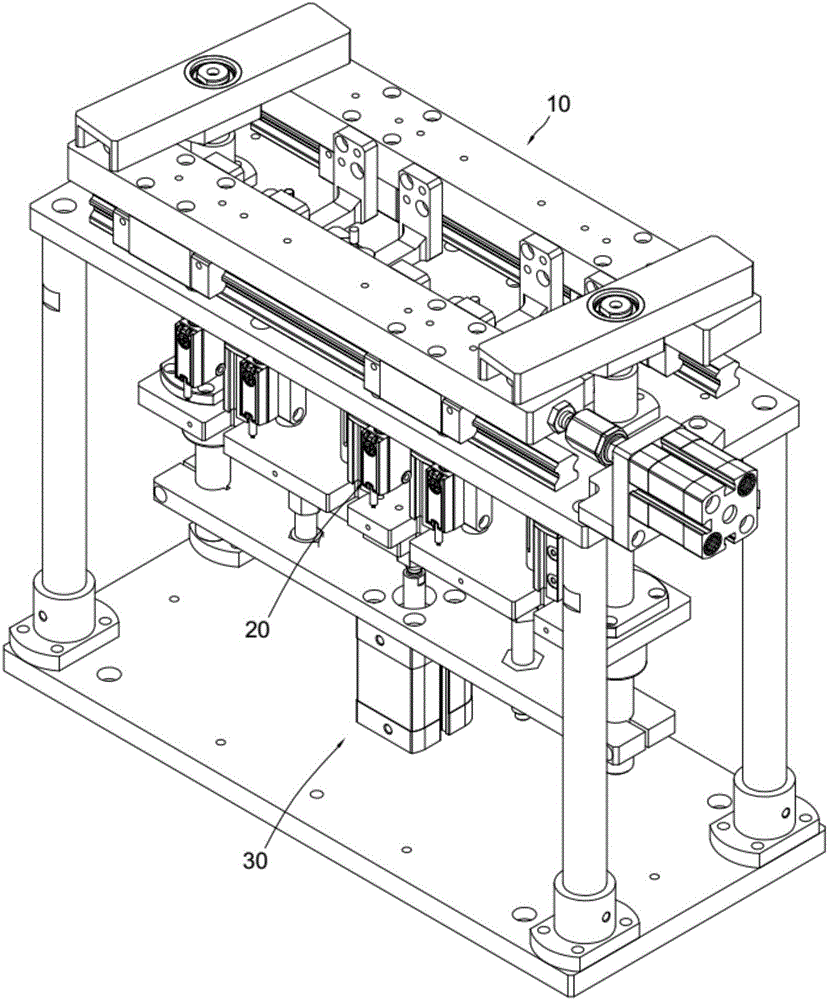

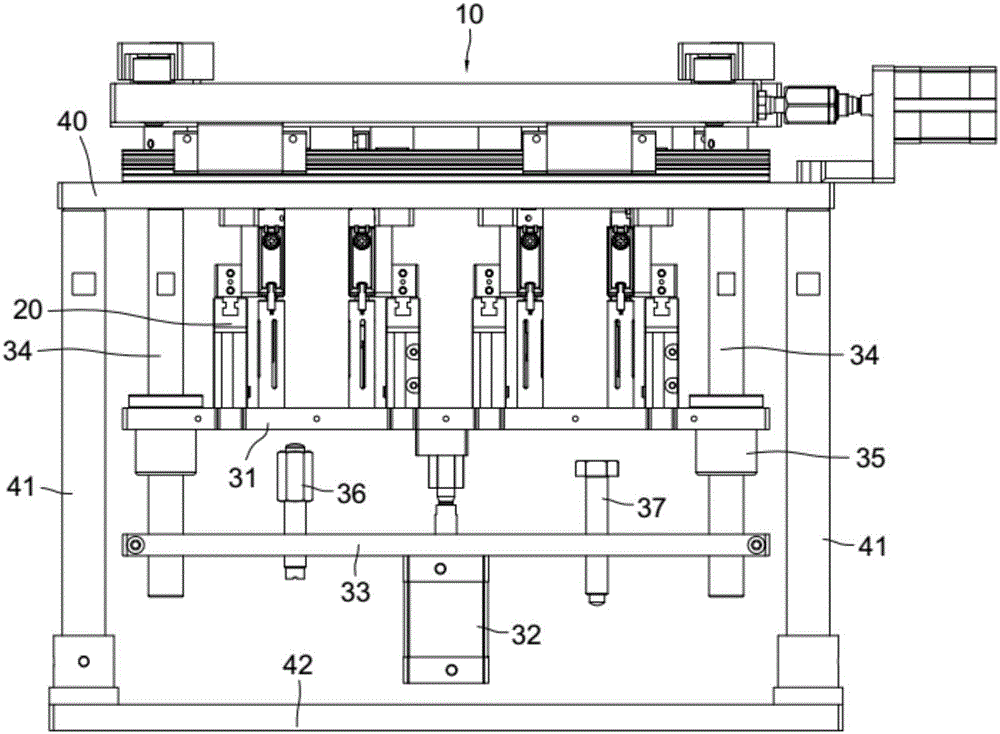

[0035] combine Figure 1 to Figure 3 , a bit quick-change mechanism, including a bit clamping mechanism 10 and a screwdriver sleeve clamping and lifting mechanism located below the bit clamping mechanism. Wherein, the screwdriver cover clamping and lifting mechanism includes four screwdriver cover clamping devices 20 and the screwdriver cover lifting mechanism 30 .

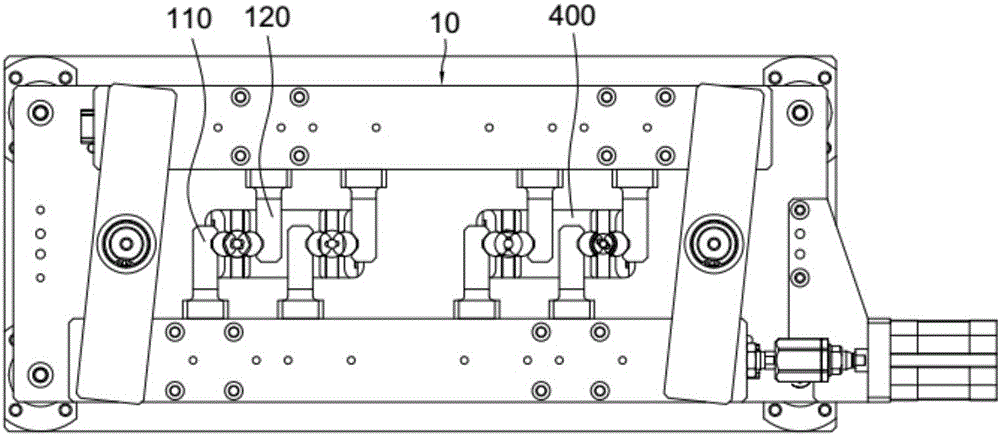

[0036] combine Figure 4 to Figure 6 , the batch head clamping mechanism 10 includes four pairs of jaws in linkage, and a batch sleeve clamping device is arranged directly below the pair of jaws. 20, the four screwdriver sleeve clamping devices are installed on the screwdriver sleeve lifting mechanism 30 on.

[0037] The bit clamping mechanism 10 includes four left jaws 110 installed on the first sliding bar 130, four right jaws 120 installed on the second sliding bar 140, the left jaws and the right jaws are alternately arranged Between the first sliding bar and the second sliding bar, the first sliding bar is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com