A special intelligent production line for elevator signal system

A signal system and special intelligent technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve problems such as damaged workpieces, poor assembly efficiency, and poor assembly quality, and achieve efficient production and assembly, quality assurance, and production safety factor high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

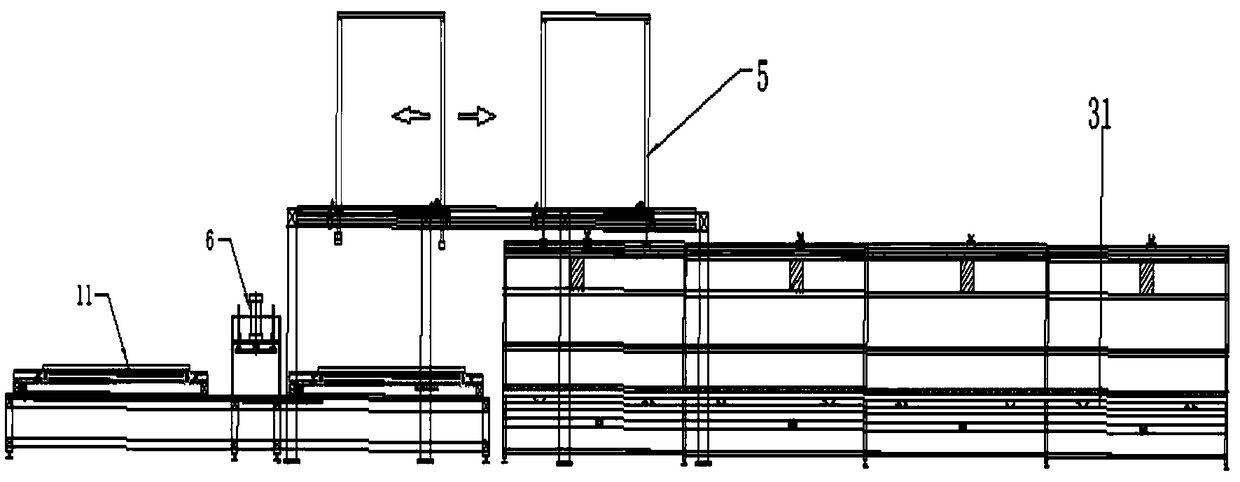

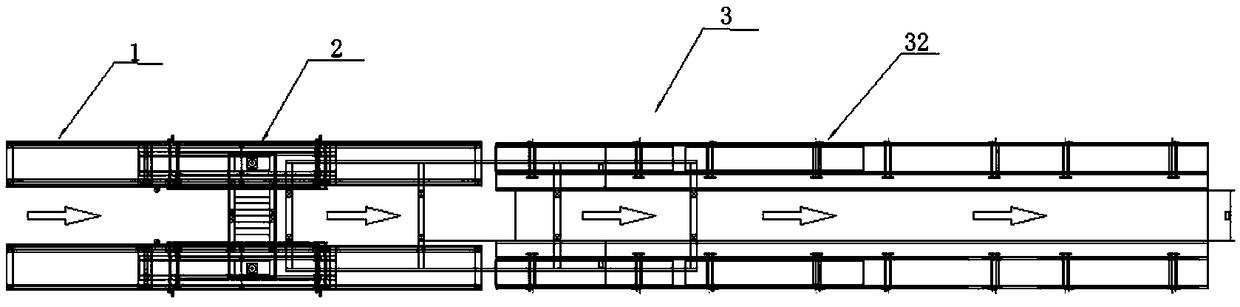

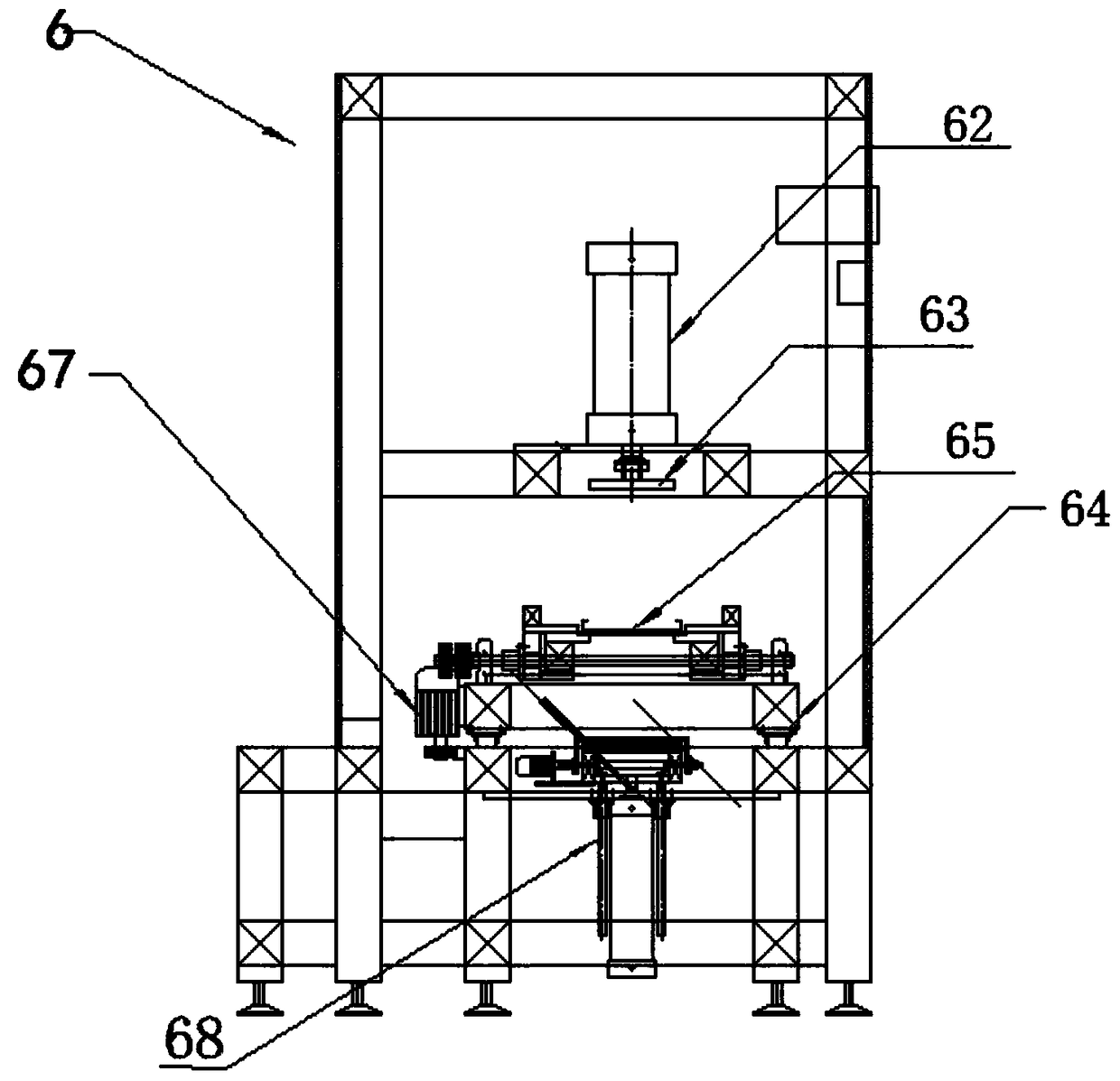

[0032] Embodiment 1: An intelligent production line dedicated to an elevator signal system, including a feeding area 1, a pressing area 2, an accessory assembly area 3, and an unloading area 4, the loading area 1, pressing area 2, and accessory assembly area 3 It is connected with the unloading area 4 in turn through the transmission track, the two sides of the feeding area 1 are provided with clamps 11, the pressing area 2 is provided with a hot-melt press 6, and the accessory assembly area 3 is provided with a bilateral assembly line 31, and a plurality of assembly partitions 32 are provided, the accessory assembly area 3 is higher than the pressing area 2, and a lifting hydraulic cylinder 5 is arranged between the accessory assembly area 3 and the pressing area 2. The hot-melt press 6 includes a support, an upper pressing area, a moving area and a lower pressing area, the moving area is arranged on the support, the upper pressing area is arranged above the moving area, and t...

Embodiment 2

[0034] Embodiment 2: On the basis of Embodiment 1, the accessory assembly area 3 is provided with a plurality of weighing detection devices, and the assembly area 32 includes an original accessory area 321, an accessory screening area 322 and an assembly area 323. The weighing detection device is in one-to-one correspondence with the assembly partitions 32. Described weighing detection device comprises sleeve pipe and photoelectric sensor, and described sleeve pipe comprises first sleeve pipe 324, second sleeve pipe 325 and the 3rd sleeve pipe 326, and described first sleeve pipe 324, second sleeve pipe 325 and The third casing 326 is connected in turn, the first casing 324 is connected to the original accessories area 321, the second casing 325 is provided with a movable opening 3251, and the movable opening 3251 is connected to the accessories screening area 322, the third The sleeve 326 is connected to the assembly area 323 , and the photoelectric sensor is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com