Fluid follow-up auxiliary supporting device for thin-walled workpiece machining

A thin-walled part processing and auxiliary support technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of workpiece deformation, increase processes, etc. The effect of reducing processing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments,

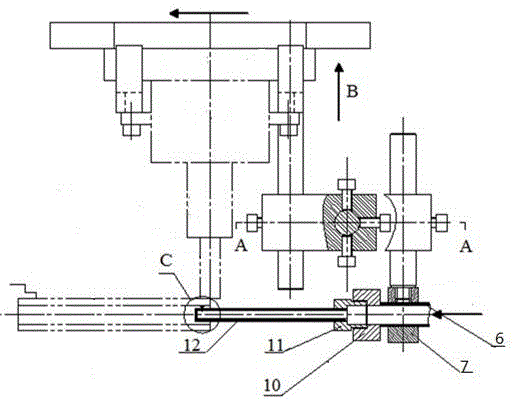

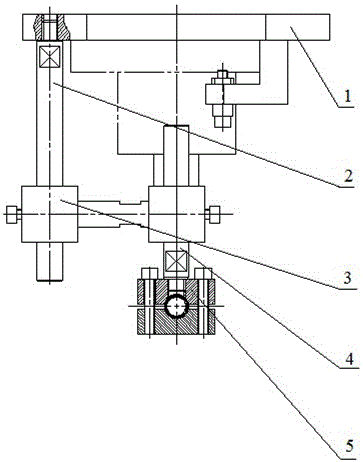

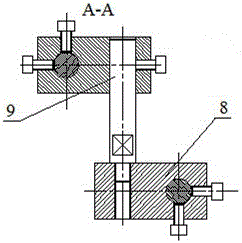

[0028] like Figures 1 to 9 As shown, the fluid follow-up auxiliary support device for thin-walled parts processing includes a support frame 1, a vertical long rod 2, a vertical long rod clamp seat 3, a vertical short rod 4, an upper half seat 5, and a pressure pump outlet pipe 6 , the lower half seat 7, the clamp seat 8 of the short horizontal rod, the short horizontal rod 9, the screw sleeve 10, the joint structure (the joint structure in the turning and milling process includes the joint 11 and the nozzle 12; in the milling process, it is only the joint 11), wherein, the support The frame 1 is fixed on the spindle box of the machine tool through bolts; one end of the vertical rod 2 is screwed to the mounting hole on the support frame 1; the vertical rod holder 3 can move up and down along the vertical rod 2 and rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com