Flexible clamping and feeding mechanism

A technology of feeding mechanism and flexible clamping, which is applied in the direction of clamping, metal processing machinery parts, supports, etc., can solve the problems of not being able to understand the structure of the flexible clamping device, and achieve simple structure, stable and reliable clamping force, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

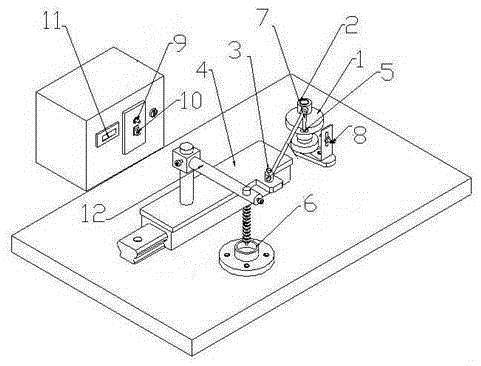

[0010] Depend on figure 1 It is known that a clamping and feeding mechanism for external processing of parts is composed of a guide rail 1, a clamping box mounting seat 2, a clamping box 3, a limit pin 4, a connecting rod 5, a locking handle 6, a working handle 7, and parts to be processed 8 , clamping block I9, clamping block II10, knife groove 11, and clamping groove 12, the clamping box mounting seat 2 is installed on the guide rail 1, the clamping box 3 is installed above the clamping box mounting base 2, and the connecting rod 5 Installed under the clamping box mounting base 2, the clamping box 3 is composed of a clamping block I31 and a clamping block II32. The clamping block I9 and the top of the clamping block II10 are provided with a corresponding clamping groove 12 at the same position as the top of the clamping block II10. The clamping groove 12 shapes correspond to the profile of the part 8 to be processed, the right side of the clamping groove 12 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com