Double-head automatic polishing machine

A technology of automatic polishing and polishing mechanism, applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. High work efficiency, compensation for loss of consumables, good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

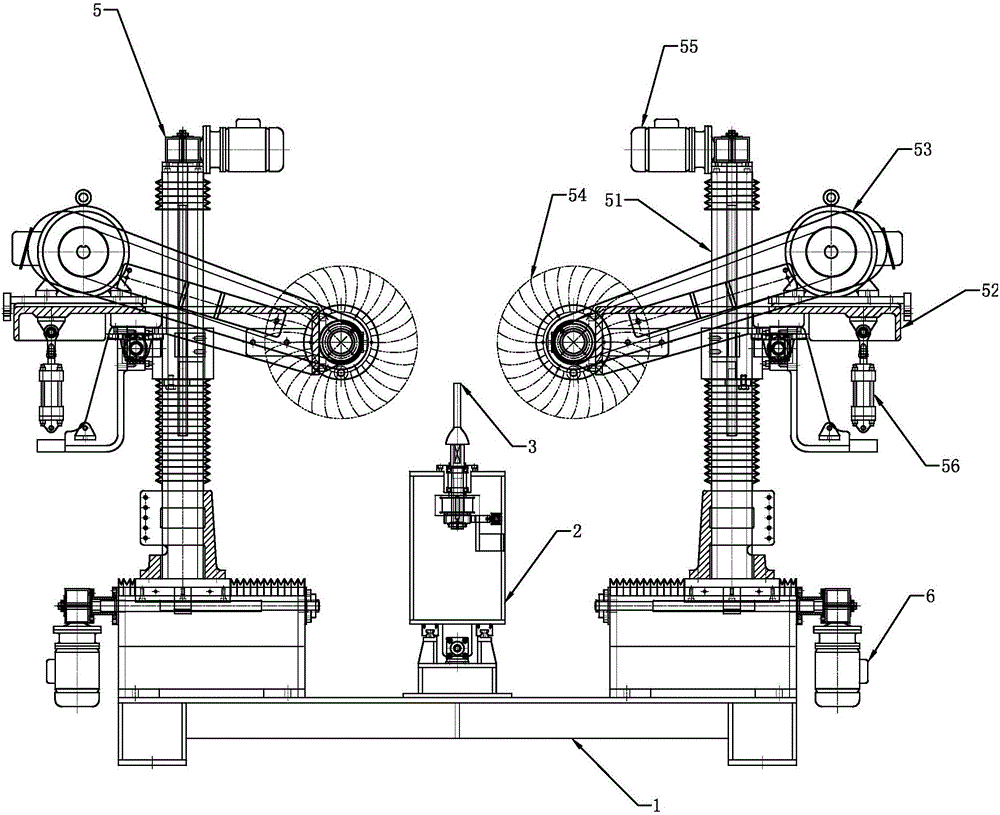

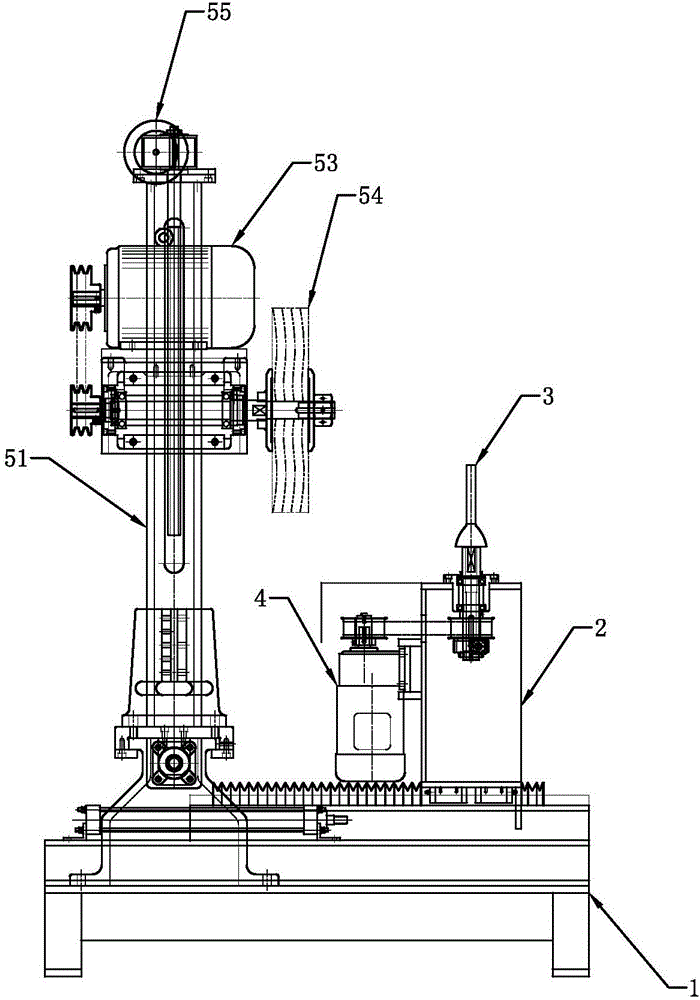

[0016] refer to Figure 1 to Figure 2 , a kind of double-head automatic polishing machine of the present invention comprises frame 1, and frame 1 center is fixedly provided with a base 2, and described base 2 is provided with rotatable polishing head 3, and described polishing head 3 is controlled by base 2 The next first motor 4 is driven to rotate, the polishing head 3 is rotatable, and there is no dead angle in the polishing of the workpiece. Two polishing mechanisms 5 are symmetrically arranged on both sides of the base 2. The polishing mechanism 5 includes a polishing arm 51 and is installed on the polishing arm 51. The fixed seat 52, the second motor 53 on the fixed seat 52 and the polishing wheel 54 driven by the second motor 53 can polish the workpiece from different angles, with high work efficiency, and can be equipped with polishing wheels of different materials to meet According to different work requirements, preferably, the second motor 53 drives the polishing wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com