Cylinder head clamping device

A technology of cylinder head and clamping block, which is applied in the direction of grinding/polishing safety devices, chucks, metal processing equipment, etc., which can solve the damage of the inner wall of the cylinder head, the large force on the cylinder head, and the small contact area between the cylinder head and the inserting arm and other problems, to achieve the effect of reducing processing steps, solving grinding difficulties, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through specific implementations:

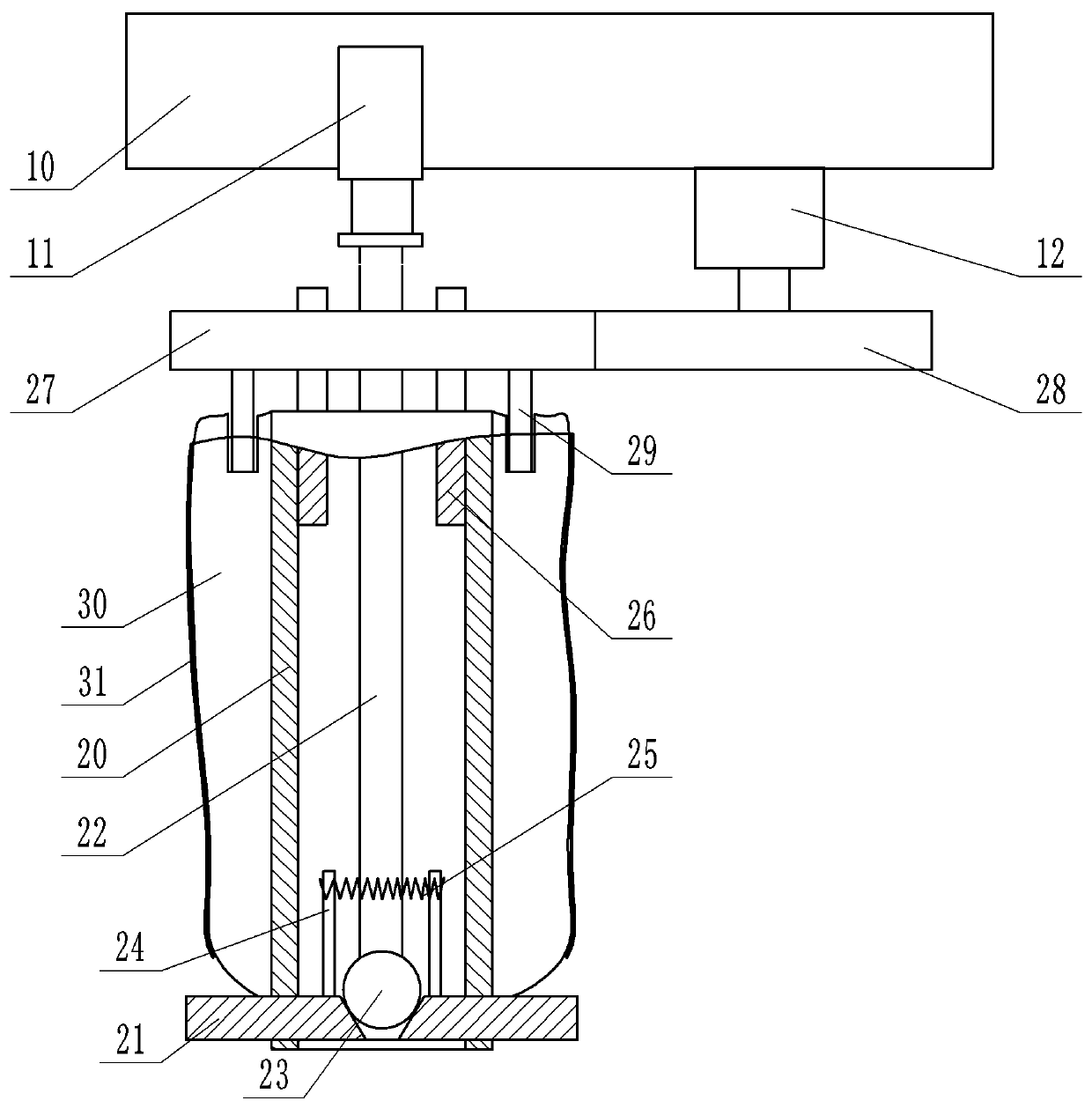

[0018] The reference signs in the drawings of the specification include: frame 10, cylinder 11, motor 12, clamping rod 20, telescopic clamping block 21, push rod 22, push ball 23, gear rod 24, ring spring 25, fixed shaft 26, The first gear 27, the second gear 28, the rotating rod 29, the air bag 30, and the sanding belt 31.

[0019] Such as figure 1 As shown, the cylinder head clamping device includes a frame 10, a clamping rod 20 and an airbag 30. The clamping rod 20 is fixed on the frame 10, the surface of the clamping rod 20 is provided with an annular groove, and the airbag 30 is sleeved in The annular groove can rotate along the annular groove. The upper surface of the airbag 30 is provided with grooves. The outer wall of the airbag 30 is provided with sand belts 31 at intervals. The outer wall of the airbag 30 is also connected with a truncated cone-shaped plug. The sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com