Automatic heat treatment device used for polylactide die

A technology of heat treatment equipment and polylactide, which is applied in the direction of household appliances, other household appliances, metal processing equipment, etc., can solve the problems of secondary softening and deformation of the mold, affecting the effect of heat treatment, and occupying a large space, so as to avoid secondary deformation, Convenient and seamless docking, to achieve the effect of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

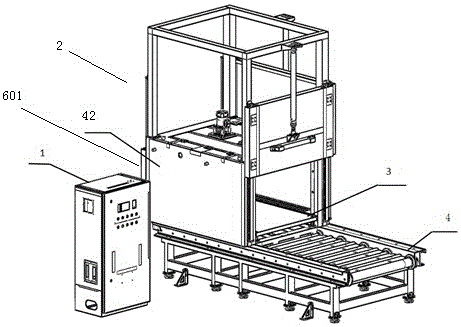

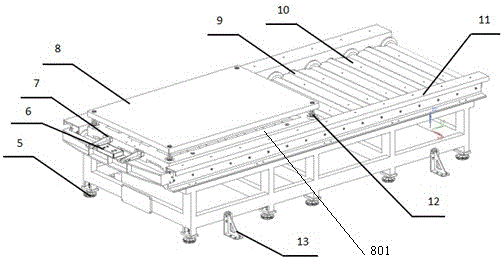

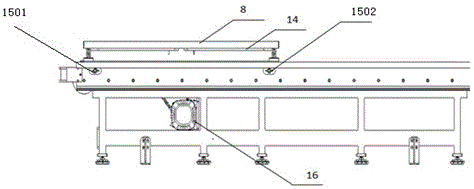

[0028]The present invention proposes a kind of automatic heat treatment equipment for polylactide material mold, according to the embodiment of the present invention, refer to figure 1 , 3 As shown in and 6, the equipment includes: automatic roller table 4, interchangeable workbench 3, oven main body 2, control cabinet 1, motor I16, workbench slideway 39 and PT100 temperature sensor 41, wherein the control cabinet The operation of the automatic heat treatment equipment described in the present invention is controlled by PLC, and the specific connection modes between the control cabinet 1 and the automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com