A blind spot detection device for a vehicle

A detection device and blind spot technology, applied in vehicle parts, optical observation devices, transportation and packaging, etc., can solve the problems of cumbersome replacement process, poor flexibility in changing lens angles, and high cost, and achieve enhanced flexibility, simple and practical structure, and high cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

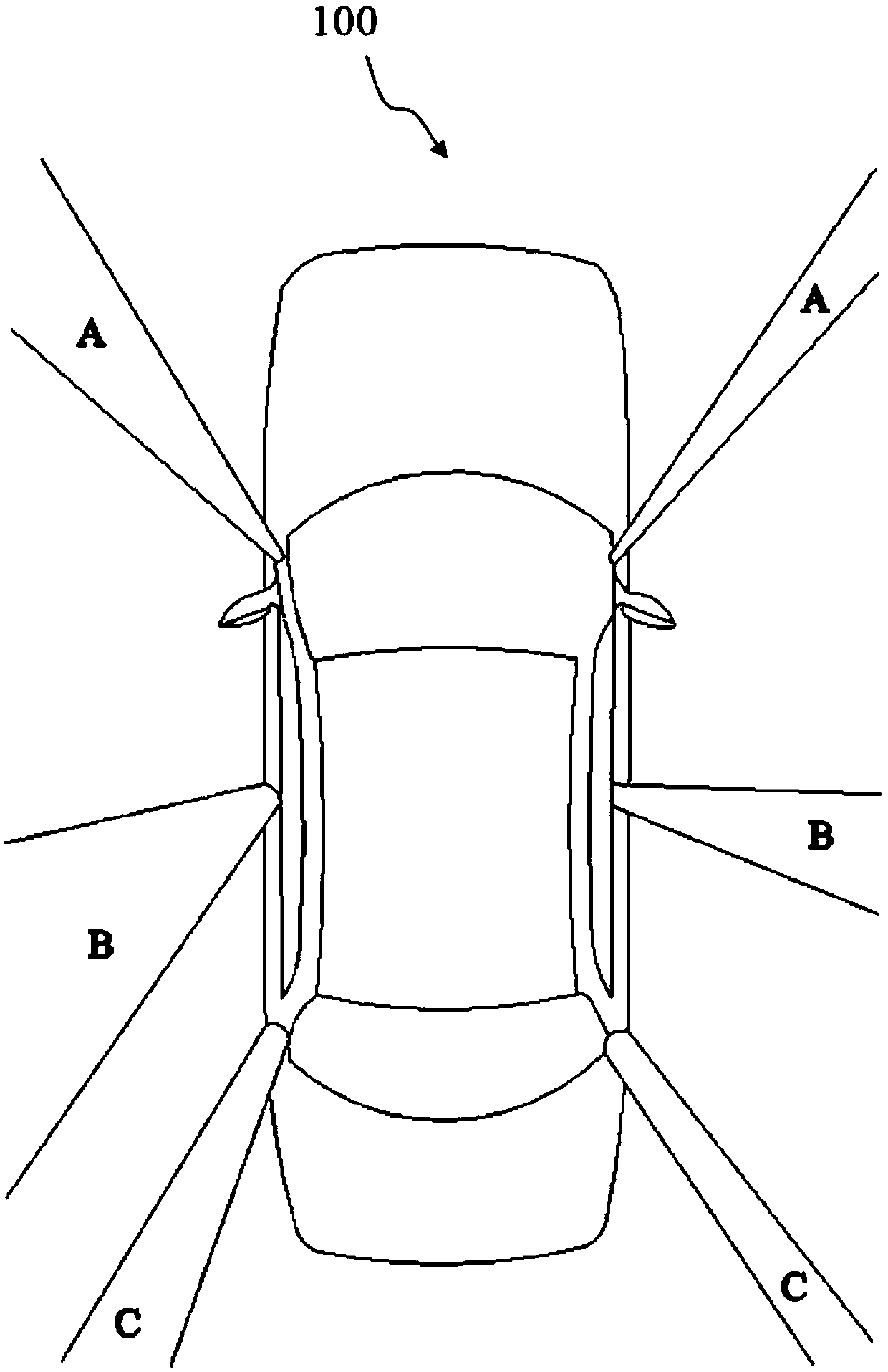

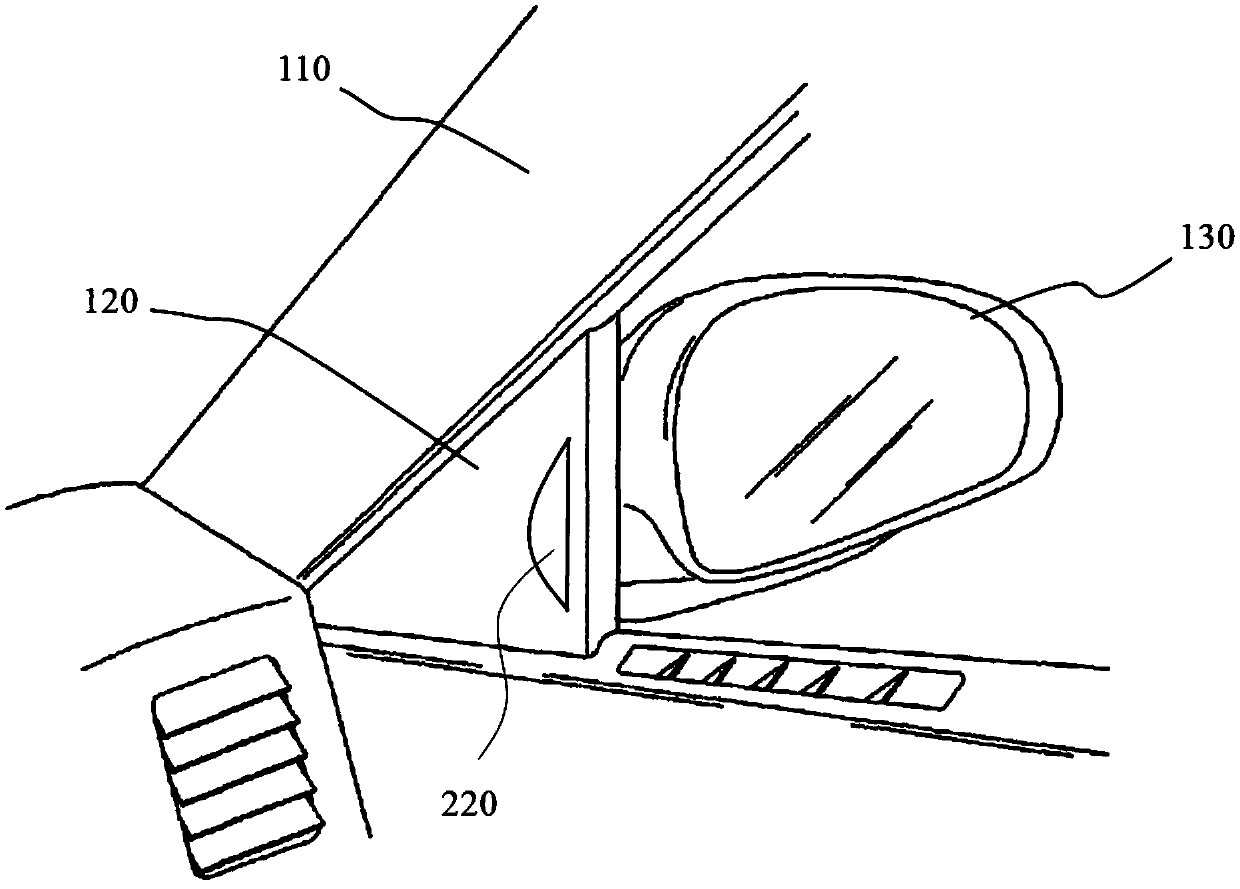

[0047] figure 1 is a schematic top view of the blind spot of the vehicle 100 . Such as figure 1 As shown, A represents the A-pillar blind area, B represents the B-pillar blind area, and C represents the C-pillar blind area. Generally, there are three types of pillars in the body of a car. From front to rear, there are front pillar 110 (A pillar), middle pillar (B pillar) and rear pillar (C pillar). For a car, the column not only acts as a support, but also acts as a door frame. The A-pillar, B-pillar and C-pillar are common knowledge in the field, and will not be described in detail here. The blind zone caused by the A-pillar is called the A-pillar blind zone. The blind zone caused by the B-pillar is called the B-pillar blind zone. The blind zone caused by the C-pillar is called the C-pillar blind zone. For safety considerations of the vehicle 100 , the B-pillar is generally relatively thick, and the angle of the rearview mirror is limited, so the B-pillar blind area is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com