Bundling and winding integration packing machine

A packaging machine and integrated technology, which is applied in the direction of bundling materials, rotating and wrapping items, etc., can solve the problems of low efficiency, equipment occupying a large space, and poor adaptability, etc., and achieve the effect of high efficiency and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be further described in detail below.

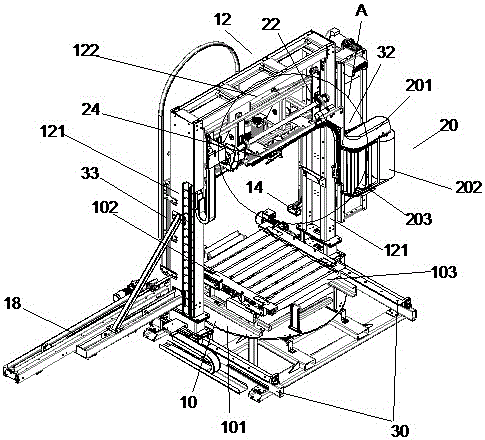

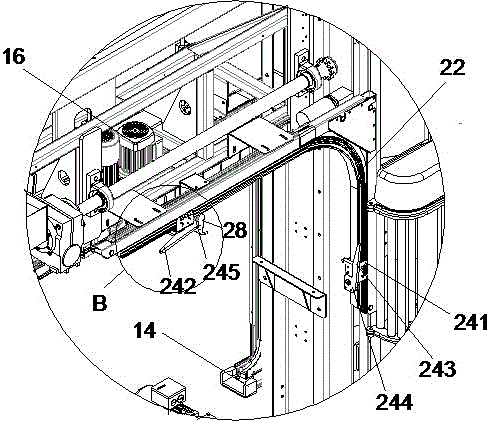

[0030] like Figure 1 to Figure 6 As shown, a kind of binding and winding integrated packaging machine of the present invention comprises:

[0031] A horizontally rotatable rotating platform 10 for placing workpieces to be packaged;

[0032] A gantry frame 12 spanning the rotating platform 10, the gantry frame 12 includes two columns 121 and a beam 122;

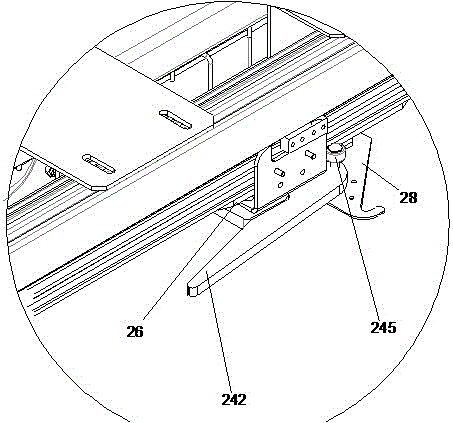

[0033] A strapping mechanism, the strapping mechanism includes a belt threading groove 14 for accommodating the strapping strap, a strapping machine head 16 for fixing both ends of the strapping strap, and a retractable arrow threading groove 18, and the strapping groove 14 is arranged on the gantry frame 12 along the direction of the gantry frame 12 When the arrow belt groove 18 extends forward, the two free ends of the belt groove 14 can be connected to form a complete channel for the strap to pass through.

[0034] A film w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com