Special-shaped bag packaging mold

A technology of special-shaped bags and molds, which is applied in the field of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

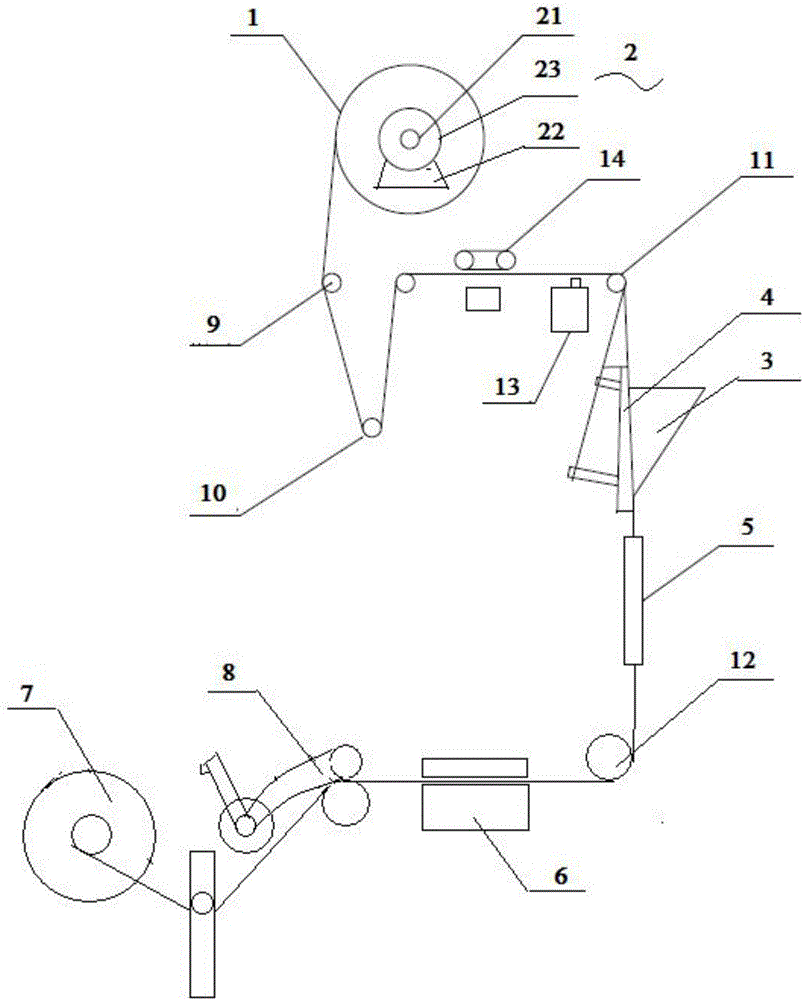

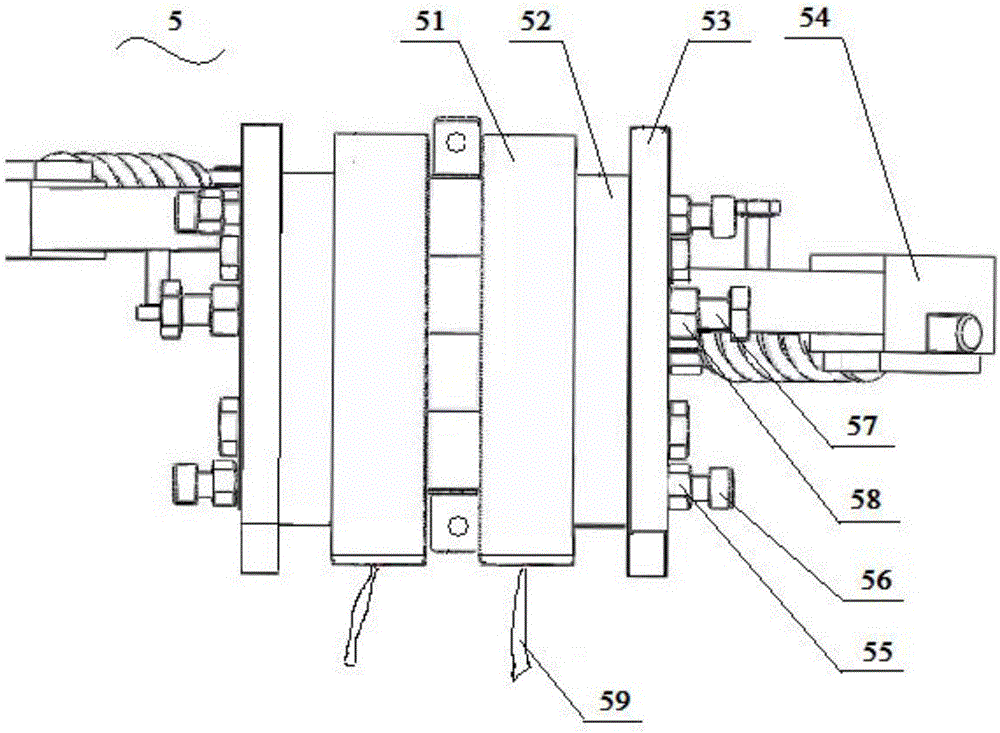

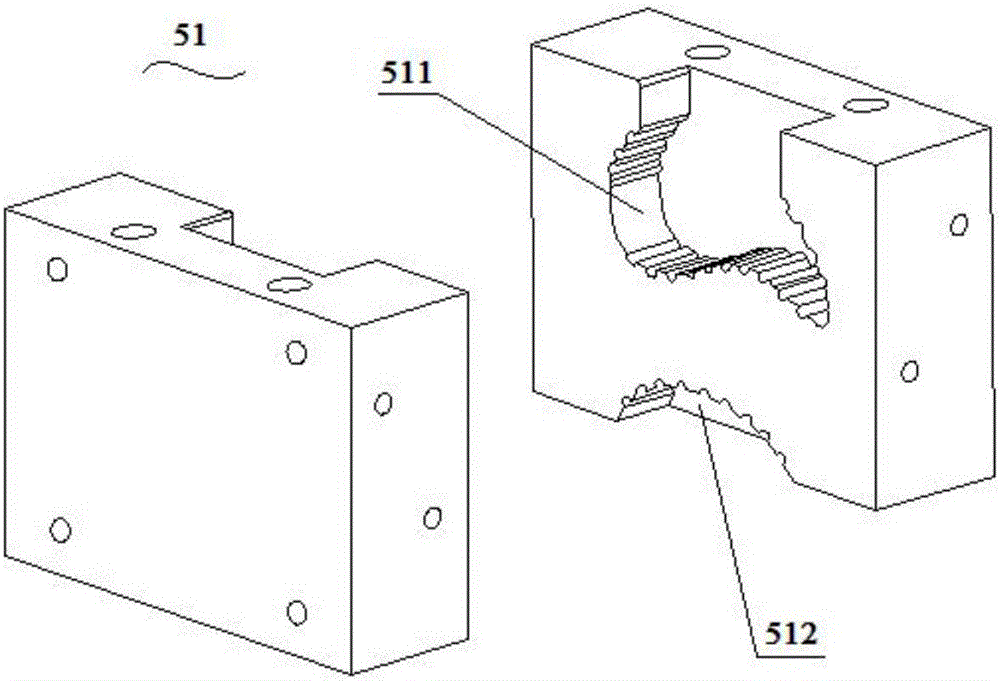

[0019] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0020] Such as Figure 2 to Figure 4 As shown, the special-shaped bag packaging mold of the present invention includes a special-shaped bag mold 5 and a blanking die 6: the special-shaped bag mold 5 includes: a left and right mold 51 for a special-shaped bag for forming and sealing a special-shaped bag, and a left and right mold for driving a special-shaped bag. The left and right swing arms 52 of the mold 51 movement and the cylinder I54 for driving the left and right swing arms 52 to move, the left and right molds 51 of the special-shaped bag and the left and right swing arms 52 are fixed on the mold fixing plate 53 by fastening nuts 55 and fastening screws 56. The fixed plate 53 is also provided with the front and rear adjustment screws 57 and the front and rear adjustment nuts 58; 522 are combined to form the shape of the special-shaped bag; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com