Spoon distribution device

A dispensing device and spoon technology, applied in packaging and other directions, can solve the problems of insufficient cleaning of tableware, waste of manpower efficiency, scratches on handling personnel, etc., and achieve the effects of simple structure, reduced labor cost, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

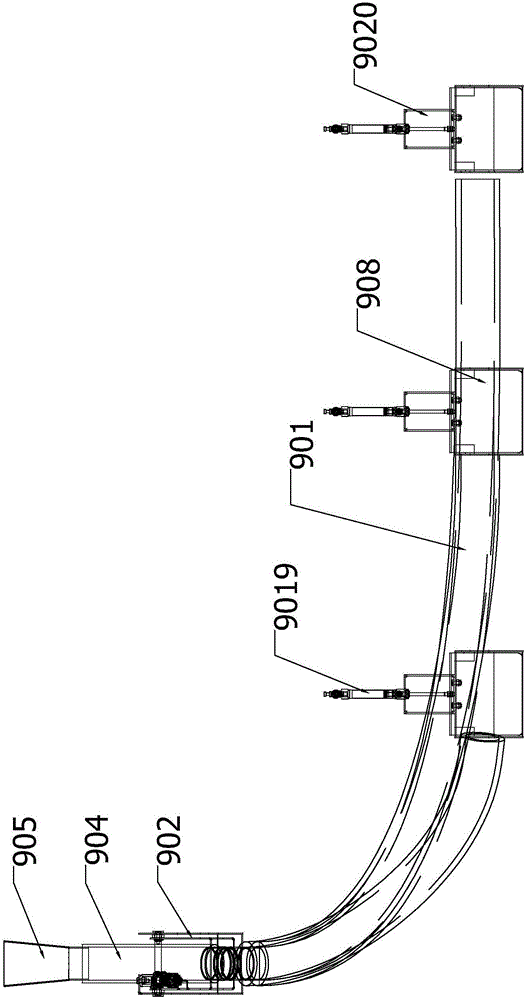

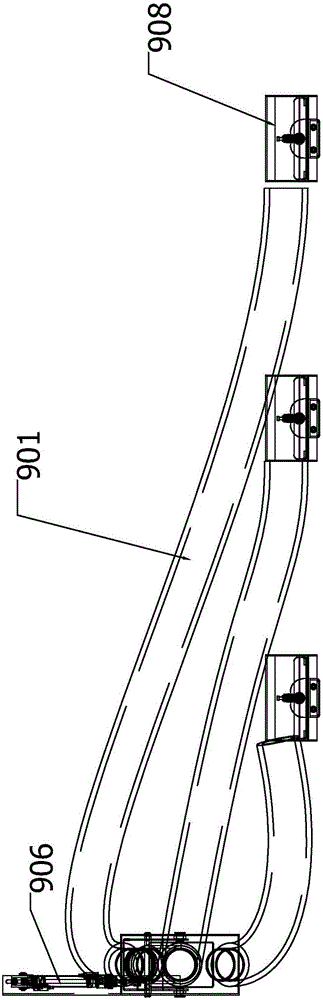

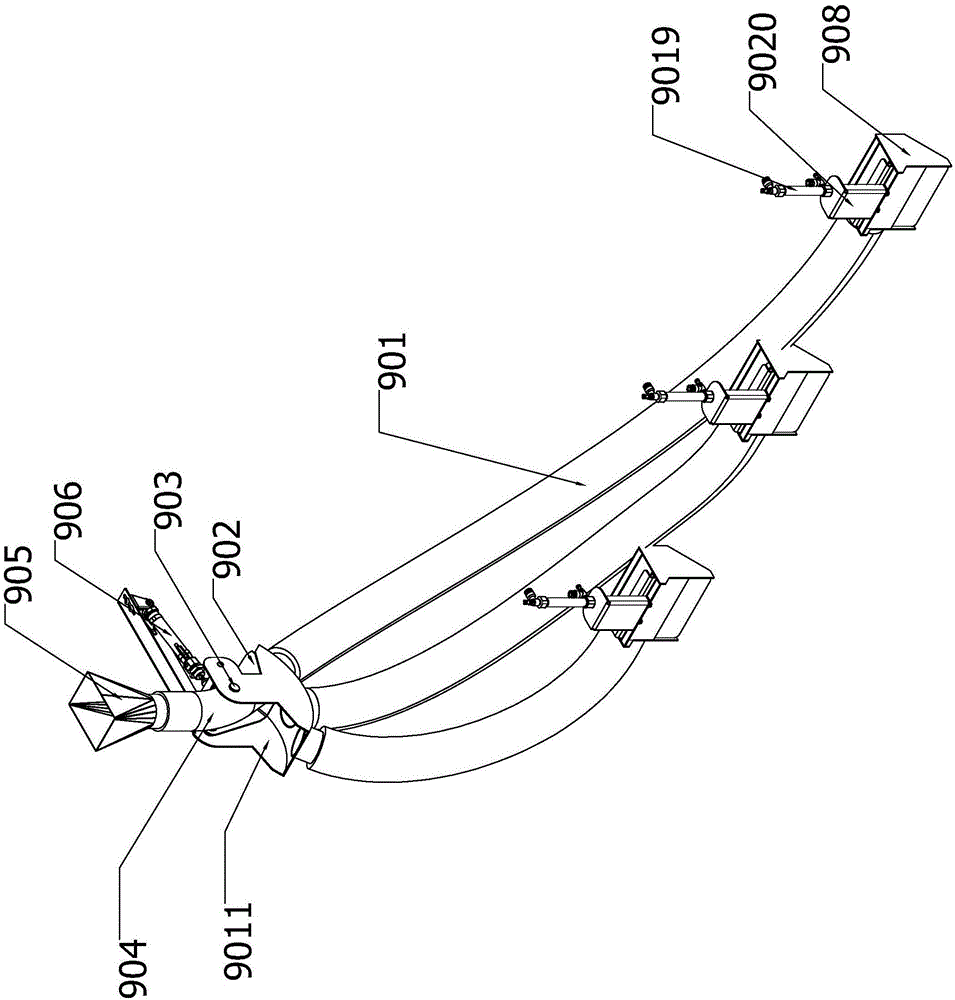

[0022] Such as Figure 1-9 As shown, the spoon distribution device includes a spoon distribution part and a spoon storage part. The spoon distribution part communicates with a plurality of spoon storage parts through a plurality of pipelines 901. The spoon distribution part is composed of a dispenser bracket assembly and a rocker welding assembly 902. The rotating part of the rocker arm welding assembly 902 is rotatably connected with both sides of the distributor bracket assembly through the rocker arm pin 903, and a plurality of openings are arranged under the distributor bracket assembly, and an opening is arranged on the rocker arm welding assembly 902, and the rocker arm The opening of the arm welding assembly 902 communicates with the scoop guide groove 905 through the skeleton hose 904, one end of the scoop distributing miniature cylinder 906 is connected with the scoop cylinder seat 907 of the distributor support assembly through a rotating shaft, and the piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com