Leachate discharging system of garbage compressor of garbage transfer station

A technology of garbage compressor and discharge system, which is applied in the directions of garbage conveying, garbage collection, transportation and packaging, can solve the problems of easy corrosion of compressors, easy leakage of sewage, and difficult to clean, so as to simplify sewage treatment methods and avoid two problems. The effect of secondary pollution and increased transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

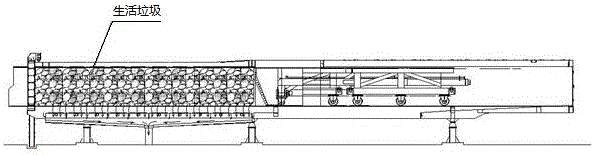

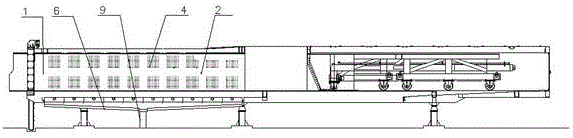

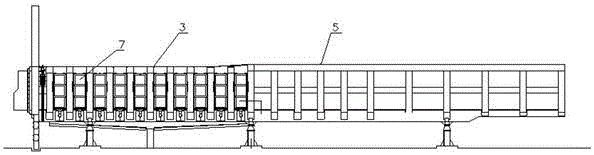

[0036] A garbage compressor leachate discharge system in a garbage transfer station, characterized in that the garbage compressor 1 includes: a pre-compression chamber 2, a compressor front end 3 and a compressor rear part 5, and the pre-compression chamber 2 is arranged at the compressor front end 3 The interior of the compressor, the compressor rear part 5 is connected with the compressor front end 3, a plurality of sewage discharge holes 4 are arranged on the side and bottom surface of the compressor front end 3, and the outer side of the compressor front end 1 bottom surface is provided with orientation As for the collection tank 6, a side drain tank 7 is provided on the outside of the side of the front end 3 of the compressor.

[0037] The side sewage discharge tank 7 is provided with a side sewage discharge tank cover door 8 .

Embodiment 2

[0039] A garbage compressor leachate discharge system in a garbage transfer station, characterized in that the garbage compressor 1 includes: a pre-compression chamber 2, a compressor front end 3 and a compressor rear part 5, and the pre-compression chamber 2 is arranged at the compressor front end 3 The interior of the compressor, the compressor rear part 5 is connected with the compressor front end 3, a plurality of sewage discharge holes 4 are arranged on the side and bottom surface of the compressor front end 3, and the outer side of the compressor front end 1 bottom surface is provided with orientation As for the collection tank 6, a side drain tank 7 is provided on the outside of the side of the front end 3 of the compressor.

[0040] The diameter range of the sewage blowdown hole 4 is 5-30mm.

[0041] The side sewage discharge tank 7 is provided with a side sewage discharge tank cover door 8 .

[0042] The side sewage tank cover door 8 can be opened and the angle at wh...

Embodiment 3

[0044] A garbage compressor leachate discharge system in a garbage transfer station, characterized in that the garbage compressor 1 includes: a pre-compression chamber 2, a compressor front end 3 and a compressor rear part 5, and the pre-compression chamber 2 is arranged at the compressor front end 3 The interior of the compressor, the compressor rear part 5 is connected with the compressor front end 3, a plurality of sewage discharge holes 4 are arranged on the side and bottom surface of the compressor front end 3, and the outer side of the compressor front end 1 bottom surface is provided with orientation As for the collection tank 6, a side drain tank 7 is provided on the outside of the side of the front end 3 of the compressor.

[0045] The sewage discharge holes 4 are uniformly arranged on the side and bottom surface of the front end 3 of the compressor.

[0046] The diameter range of the sewage blowdown hole 4 is 5-30mm.

[0047] The side sewage discharge tank 7 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com