Automated express package sorting mechanism

A rack and power technology, applied in the field of automatic express sorting and training institutions, can solve the problems of low express sorting efficiency, low single-channel efficiency, low automation level, etc., and achieves a high degree of automation, convenient operation, and large sorting volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

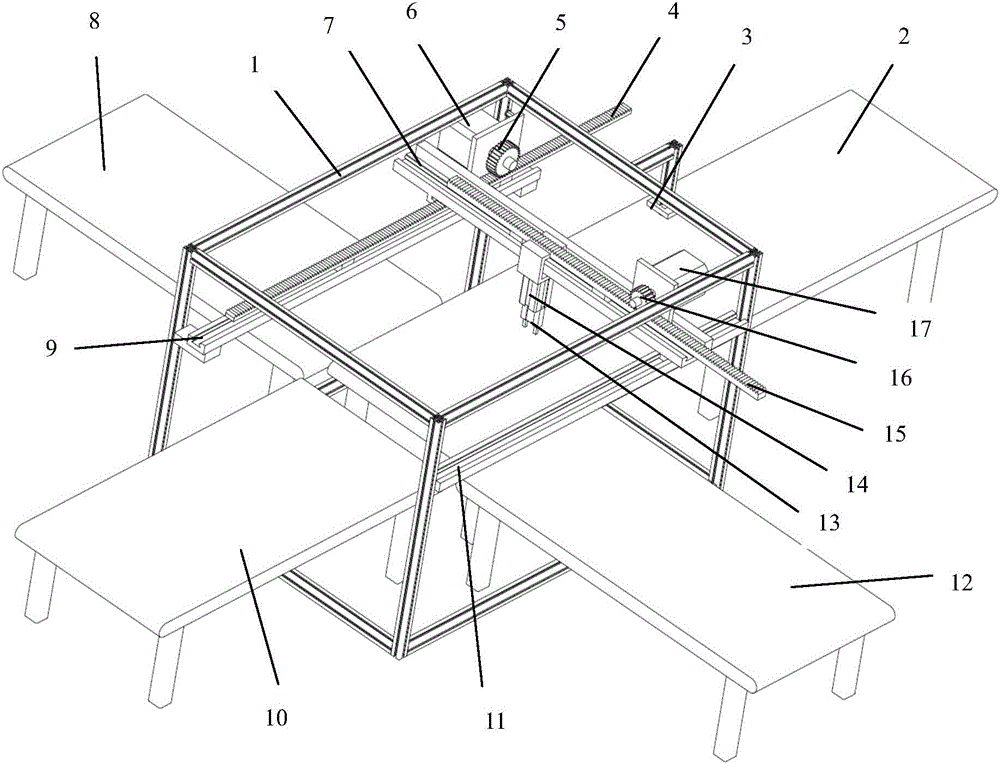

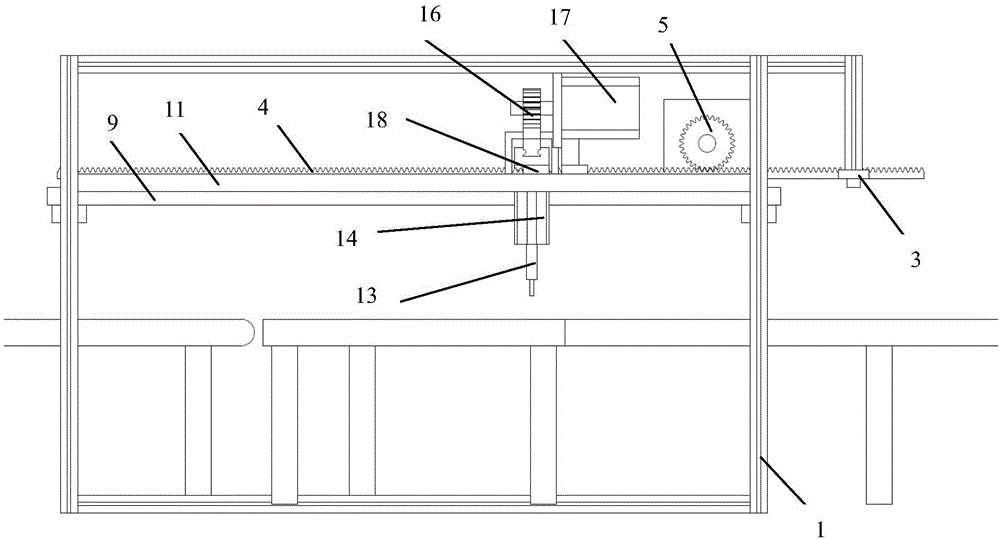

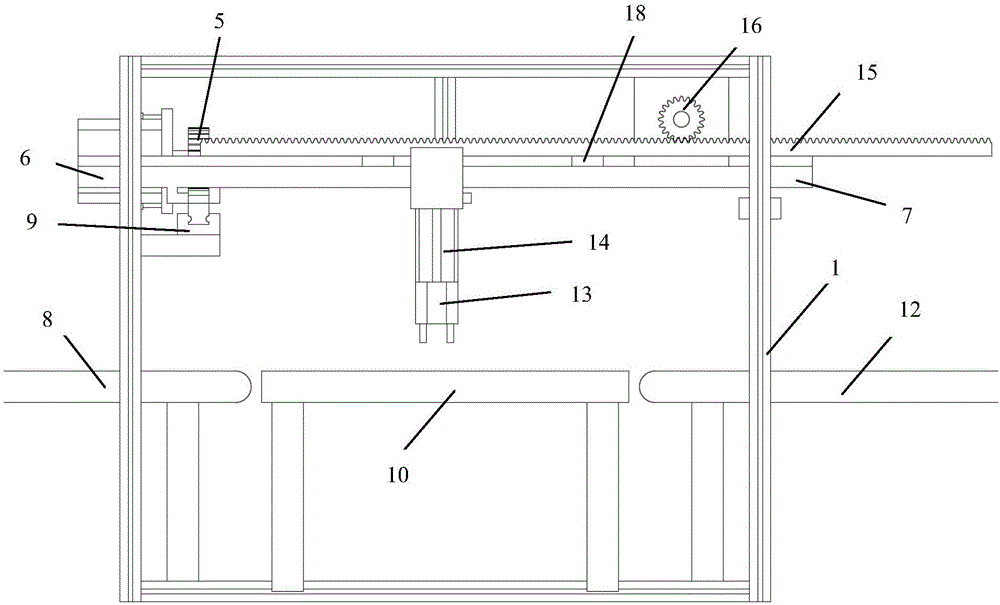

[0022] combined with figure 1 and 2 , an automatic express sorting mechanism, comprising a frame 1, an express input conveyor belt 2, a first express delivery output conveyor belt 8, a second express delivery output conveyor belt 9 and a third express delivery conveyor belt 12; the frame 1 is a rectangular structure, and the machine A first guide rail 9 and a second guide rail 11 are arranged in parallel on both sides of the frame 1; a first rack 4 is slidably arranged on the first guide rail 9, and the first rack 4 meshes with the first gear 5, and the first gear 5 Driven by the first motor 6, the first motor 6 is arranged on the frame 1; the first guide rail 9 and the second guide rail 11 are vertically provided with a third guide rail 7 through a slider 18; slide on the third guide rail 7 A second rack 15 is provided, the second rack 15 meshes with the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com