Fluidized reseparator

A fluidization and body technology, applied in chemical instruments and methods, separating solids from solids with airflow, magnetic separation, etc., can solve problems such as inability to operate online, inappropriate, poor separation effect, etc., and is easy to popularize , wide application range, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

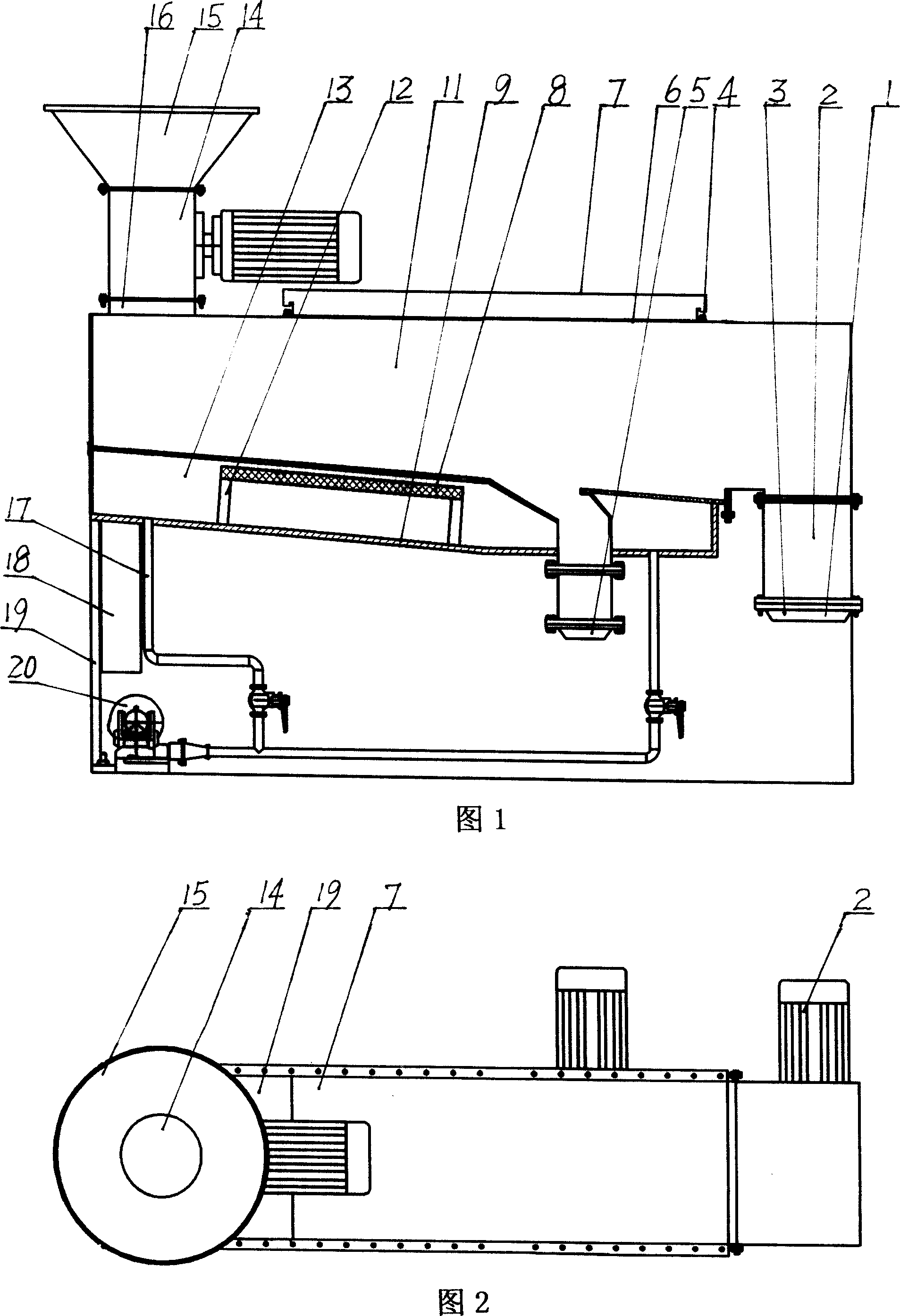

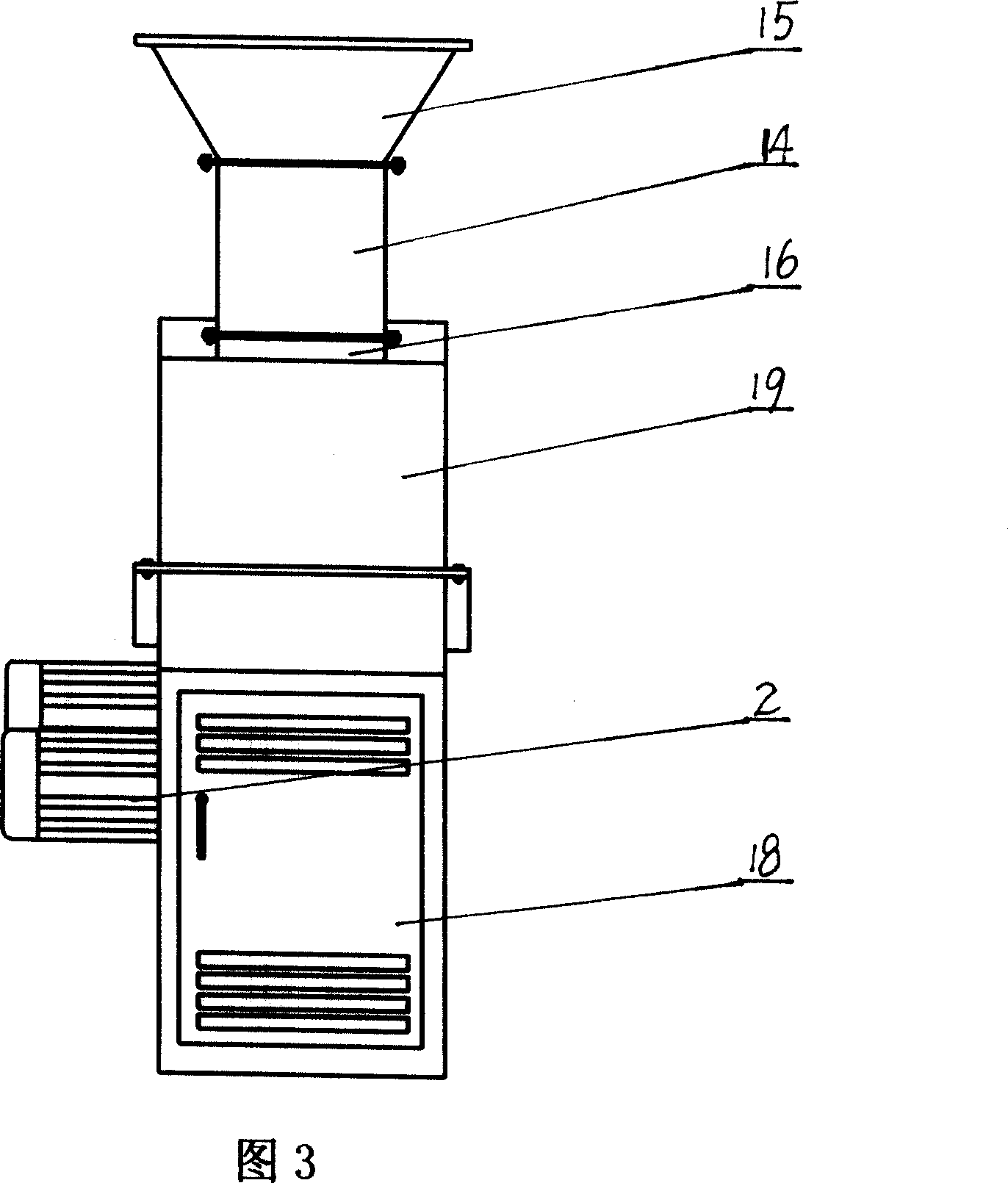

[0025] The present invention comprises a body 19, an inclined air-permeable cloth 9 is arranged between the upper groove cavity 11 and the lower groove cavity 13 of the body 19; The support 12 in the lower groove cavity 13 of the bottom is provided with electromagnet 8;

[0026] Vent hole 4 can be arranged on the exhaust cover 7 on the body 19, and air-permeable cloth 6 is arranged on the body 19 below the exhaust cover 7.

[0027] There are two outlets 1, namely primary outlet 5 and secondary outlet 3; materials with relatively large specific gravity and relatively large particles are discharged from primary outlet 5; materials with relatively small specific gravity and small particles are It is discharged from the secondary outlet 3.

[0028] The air inlet pipe 17 can be set to two, respectively at the high place and the low place corresponding to the inclined air-permeable cloth 9 .

[0029] Also can be provided with hopper 15, feeder 14 on feed inlet 16; Feeder 14 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com