A load-bearing tool that can be quickly unloaded

A heavy tooling and fast technology, applied in the field of mechanical tooling, can solve the problems of high labor intensity, complex structure, complicated production and maintenance process, etc., and achieve the effects of simple production, small lifting force, and fast implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

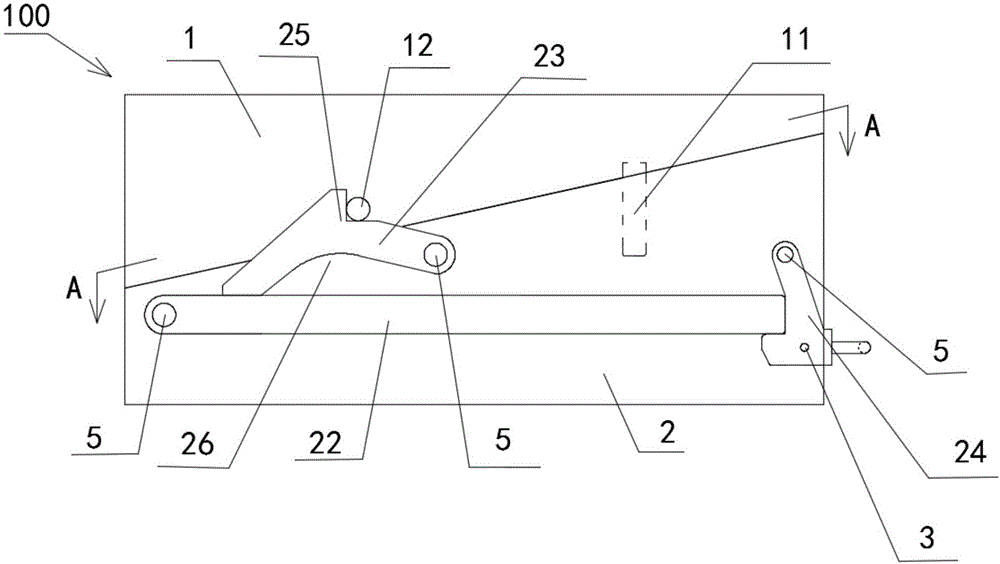

[0035] Such as figure 1 As shown, the load-bearing tool that can be quickly unloaded in the present invention includes: an upper wedge-shaped box 1 and a lower wedge-shaped box 2 , and the upper and lower wedge-shaped boxes are wedged with each other to form a whole box 100 in the shape of a cube. In this embodiment, the contact surface of the upper and lower wedge-shaped boxes is an inclined surface, and the angle α between the inclined surface and the horizontal plane satisfies the self-slip between the upper and lower wedge-shaped boxes, that is, tanα≥u, where u is the coefficient of friction.

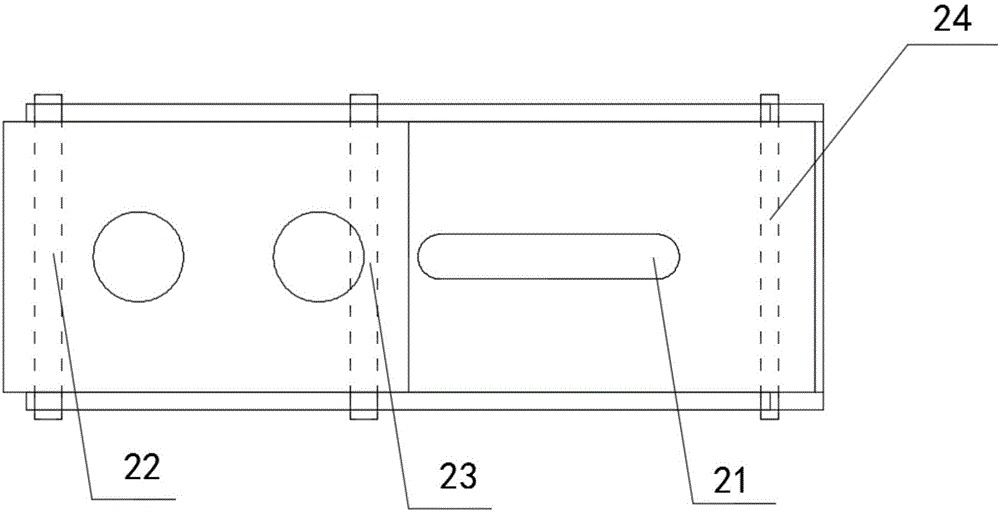

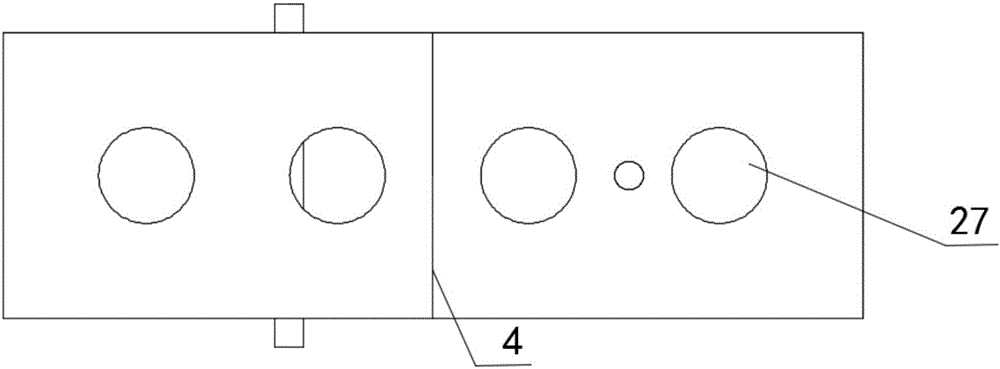

[0036] Such as figure 1 with 2 As shown, the upper wedge-shaped box 1 is fixedly provided with a limit pin 11, and the lower wedge-shaped box 2 is provided with a limit groove 21, and the limit pin 11 vertically extends into the limit groove 21, so that the upper and lower wedge-shaped When the box is relatively sliding, the limit groove 21 limits the limit pin 11, and when the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com