Hydrodynamic cavitation sewage treatment equipment

A kind of sewage treatment equipment, hydraulic cavitation technology, applied in the direction of heating water/sewage treatment, mechanical oscillation water/sewage treatment, etc., can solve the problems that cannot meet the requirements of environmental protection, reduce emissions and damage to the environment, and improve purification effect, the effect of reducing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

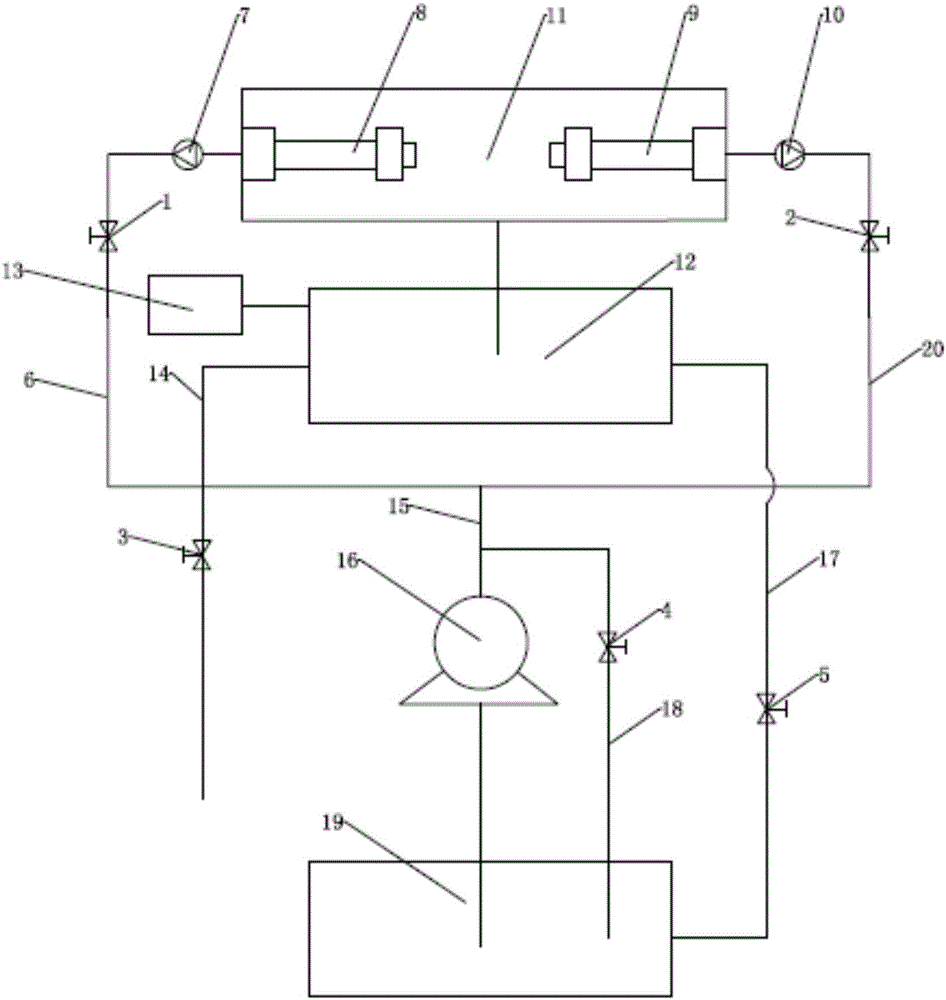

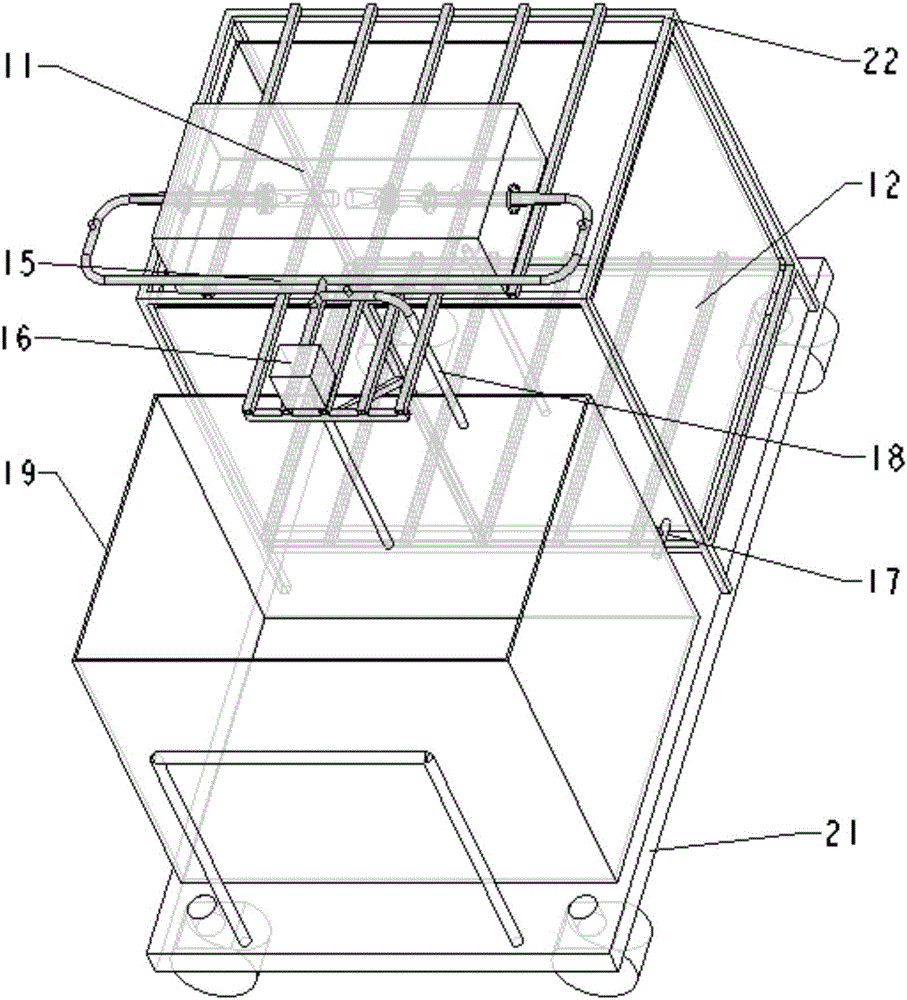

[0014] With reference to accompanying drawing, a kind of hydraulic cavitation sewage treatment equipment comprises a water pump (16), a set of main pipeline (15), cavitator 1 (8), cavitator 2 (9), an impingement flow chamber (11), Pressure gauge 1 (7), pressure gauge 2 (10), valve 1, valve 2, valve 3, valve 4, valve 5, water tank 1 (12), water tank 2 (19), a detection device (13), a drain Pipe (14), a return pipe (17), an overflow pipe (18), branch pipeline 1 (6), branch pipeline 2 (20).

[0015] The water tank 2 (19) is connected to the water pump (16) through the pipeline; the water pump is connected to the main pipeline (15) and the overflow pipe (18), and a valve (4) is added on the overflow pipe (18), and the overflow pipe (18) is connected to To water tank 2 (19); the main line (15) connects branch line 1 (6) and branch line pipe 2 (20), and then connects to cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com