Whole glass tube processing system of medium-high temperature solar heat collecting tube

A technology of solar heat collecting tube and processing system, which is applied in the field of medium and high temperature solar heat collecting tube glass tube processing system, which can solve the problems of lack of automation, uneven product quality and low efficiency, so as to reduce the use of labor and improve automation degree, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content of the present invention in detail and achieve the target effect, it will be described in detail below in conjunction with the embodiments.

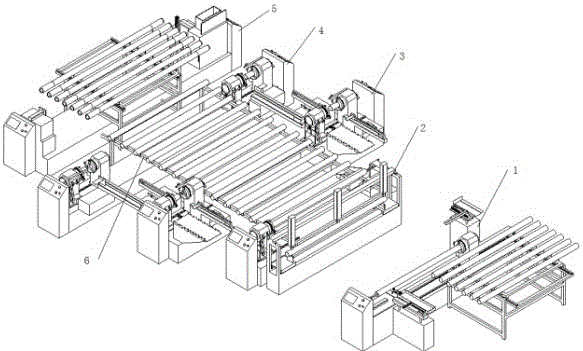

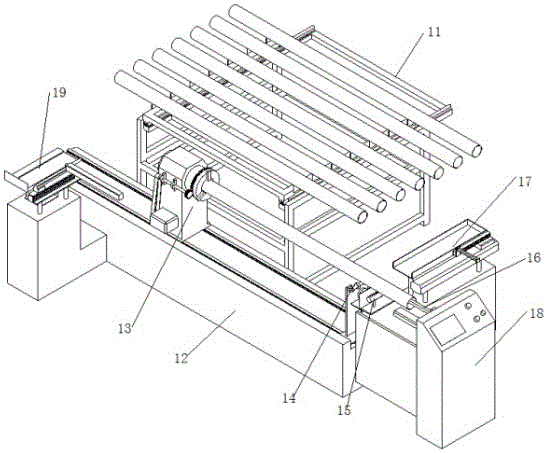

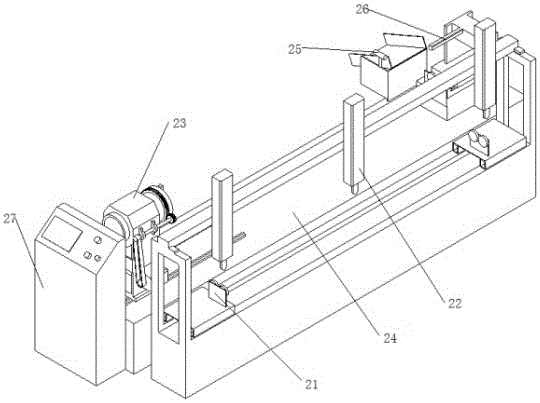

[0023] Refer to attached figure 1 - attached Figure 6 , the present invention provides a kind of whole tube glass tube processing system of medium and high temperature solar heat collector tube, along the glass tube processing direction, there are 280 section cutting equipments for cutting the glass tube into 280mm glass section successively. Glass tube cutting equipment for measuring straightness and cutting qualified glass sections to length into required glass sections 2. Glass-Kvar sealing equipment for sealing 280mm glass sections and Kovar into 300 sections 3. Glass-glass sealing equipment for sealing 300 sections and glass sections cut to length 4. Tailpipe sealing equipment for sealing tailpipes to glass sections 5. The 280 sections cut There is a conveying rack 6 between the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com