Target rod removing device

A target stick and baseball technology, applied in the field of auxiliary facilities, can solve the problems of unbalanced force application, damage to the target stick, the quality of the optical fiber preform and the influence of the utilization rate, etc., to achieve the effect of ensuring balance and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following examples, but the descriptions of the examples are not intended to limit the solutions of the present invention. Equivalent transformations that are only formal but not substantive should be regarded as the scope of the technical solution of the present invention.

[0020] In the following descriptions, all directional or azimuth concepts such as up, down, left, right, front, back, top and bottom are aimed at figure 1 As far as the current position is concerned, it cannot be understood as a special limitation on the technical solution provided by the present invention.

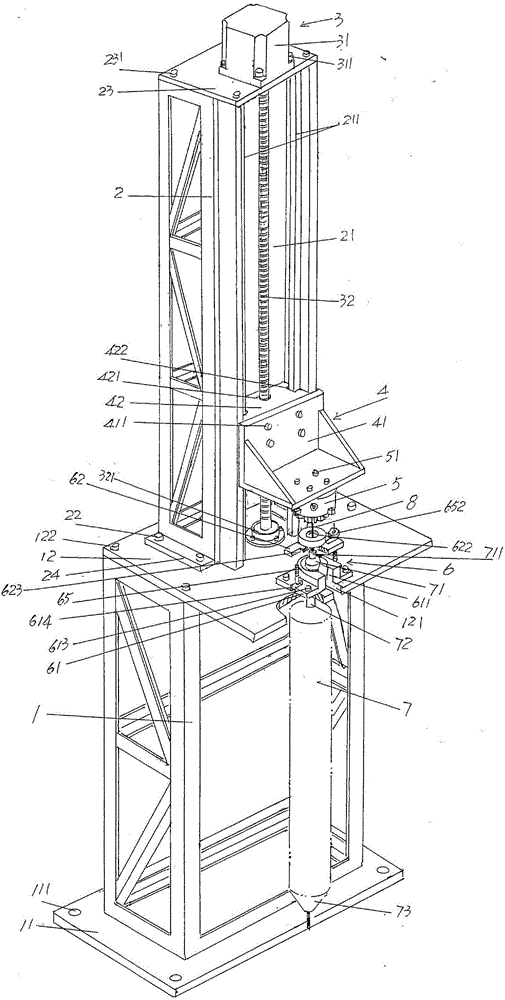

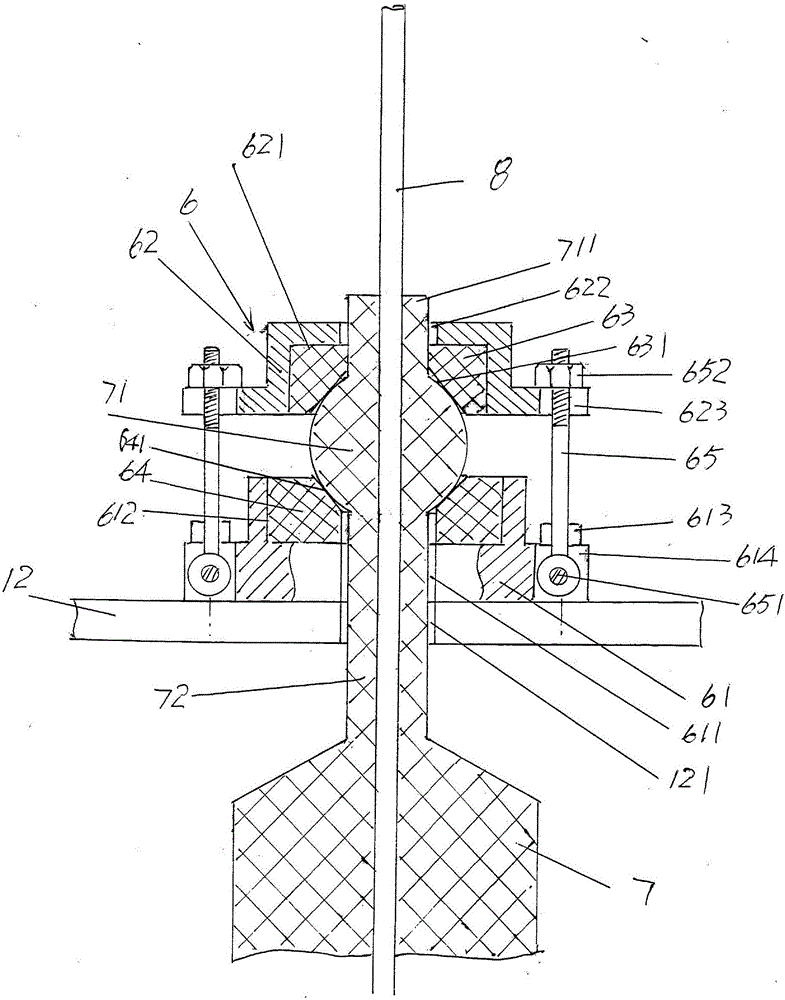

[0021] See figure 1 , showing a hollowed-out frame-shaped base 1; showing a hollow-out frame-shaped lifting slide support frame 2, which is fixed to the top of the aforementioned base 1; showing A lifting slide drive mechanism 3, the lifting sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com