A function-enhanced granular composite soil conditioner

A kind of soil conditioner, granular technology, applied in the field of function-enhanced granular composite soil conditioner, can solve the problems of inconvenient transportation, storage and use, easy to generate a lot of dust, low compressive strength of particles, etc., to achieve Comprehensively strengthen and upgrade, achieve nutritional content and functions, improve performance and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

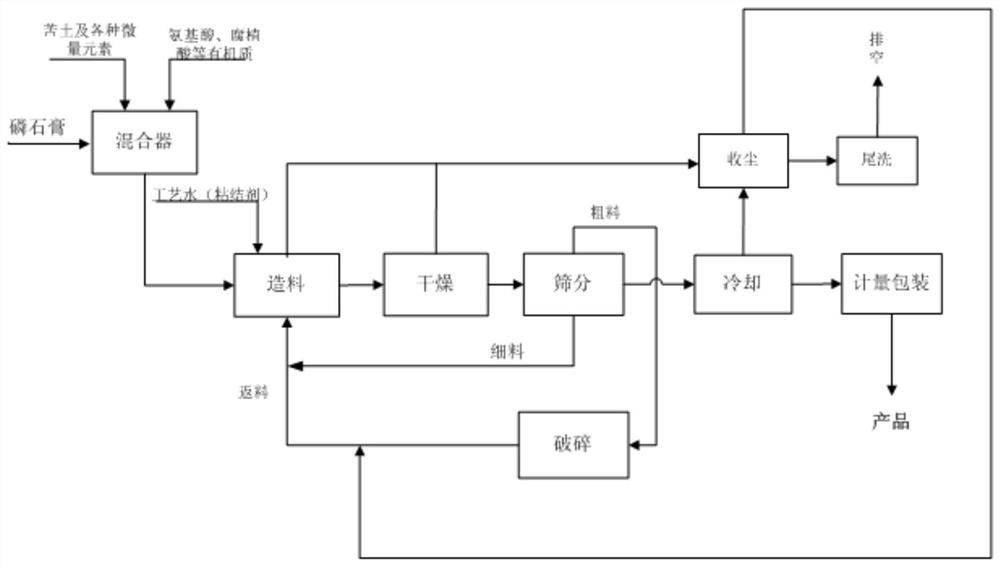

[0032] like figure 1 As shown, weigh 90.0 parts of phosphogypsum, 7.0 parts of bitter soil, 0.67 parts of boron oxide, 1.2 parts of zinc oxide, 1.3 parts of manganese oxide, 0.31 parts of molybdenum oxide, 6.0 parts of amino acid raw powder, and 10.0 parts of humic acid. Mix well in the mixer, send it to the disc granulator, add appropriate amount of process water for granulation, then send it to the drum dryer for drying, then enter the drum cooler for cooling, and finally sieve, measure and pack to get product.

[0033] The soil conditioner produced by the method contains the following quality (in mass percent) components:

[0034] S 11.56%; Ca 14.97%; Mg 3.12%; B 0.17%; Zn 0.80%; Mn 0.83%;

[0035] Average compressive strength of particles: 38N; moisture 2.3%; pH 9.6

[0036] The particles of the product produced in this example are round and uniform, and the average compressive strength of the particles reaches 38N. The particles are not easily broken or pulverized duri...

Embodiment 2

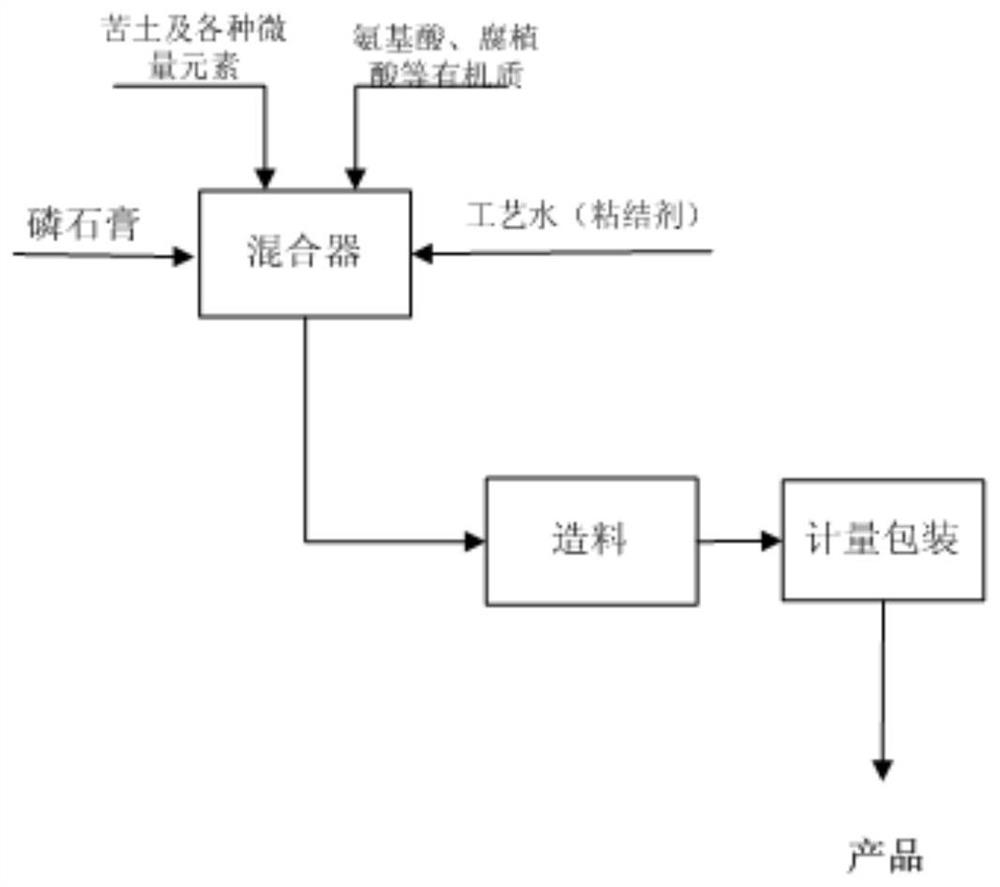

[0040] like figure 2 As shown, repeat Example 1, weigh 80.0 parts of phosphogypsum, 5.0 parts of bitter soil, 0.26 parts of boron oxide, 0.13 parts of zinc oxide, 0.13 parts of manganese oxide, 0.15 parts of molybdenum oxide, 5.0 parts of amino acid powder, humic acid 10.0 parts, add an appropriate amount of process water, fully mix evenly in a twin-shaft mixer, and send it to an extrusion granulator (screw granulator) for granulation, metering and packaging to obtain the product.

[0041] The soil conditioner produced by the method contains the following quality (in mass percent) components:

[0042]S 12.03%; Ca 15.41%; Mg 2.58%; B 0.077%; Zn 0.10%; Mn 0.097%;

[0043] Average compressive strength of particles: 35N; moisture 2.4%; pH 8.7

[0044] Due to the appropriate content of trace elements in the product, it can be applied to acidic or weakly acidic soil alone.

[0045] The particles of the product produced in this example are round and uniform, and the average compr...

Embodiment 3

[0048] like figure 1 As shown, repeating Example 1, there are the following differences: Weigh 70.0 parts of phosphogypsum, 2.0 parts of bitter soil, 0.064 parts of zinc oxide, 0.067 parts of manganese oxide, 0.13 parts of boron oxide, 0.08 parts of molybdenum oxide, and the original powder of amino acid 3.0 parts, 10.0 parts of humic acid, fully mixed in the trough mixer, sent to the drum granulator, added an appropriate amount of process water (0.1 part of water glass is brought in by the process water) for granulation, and then sent to the fluidized bed dryer for drying, and then into the drum cooler for cooling, and finally sieved, measured and packaged to obtain the product.

[0049] The soil conditioner produced by the method contains the following quality (in mass percent) components:

[0050] S 12.35%; Ca 15.98%; Mg 1.22%; Zn 0.059%; Mn 0.59%; B 0.046%;

[0051] Average compressive strength of particles: 33N; water content 2.3%; pH 6.7.

[0052] Due to the appropria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com