PMMA modified thin film and manufacture method thereof

A production method and film technology, which can be applied to other household appliances, applications, household appliances, etc., can solve the problems of fragility and easy folding, and achieve the effects of fast speed, improved weather resistance, and rich range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

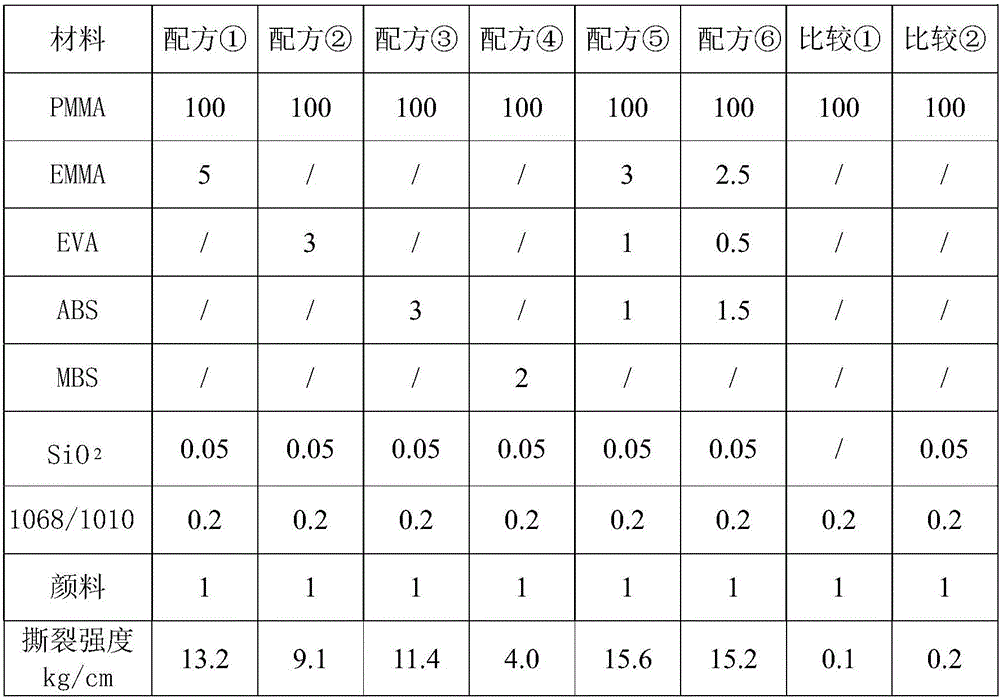

[0016] A PMMA modified film, including a main material composed of 80-100PHR PMMA, 0-10PHR EVA, 0-10PHR EMMA, 0-5PHRABS and 0-5PHR MBS; a lubricant with a weight of 0.1-10% of the main material; the main material 0.1-10% by weight of antioxidant; 0.05-0.5% of filler by weight of main material; and 0-10% of pigment by weight of main material. Its production method comprises the following steps:

[0017] A. Mix the main ingredients in proportion, add some antioxidants, put them in a kneader, and knead evenly at low temperature to obtain PMMA modified materials;

[0018] B. Add lubricant, residual antioxidant, filler and pigment to the PMMA modified material in proportion, and then put it into a kneader and knead evenly at low temperature;

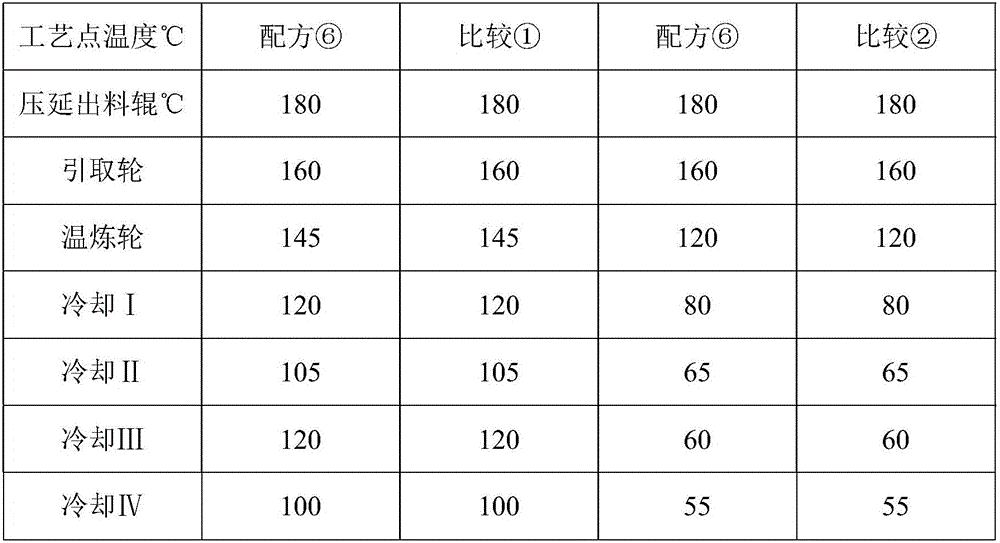

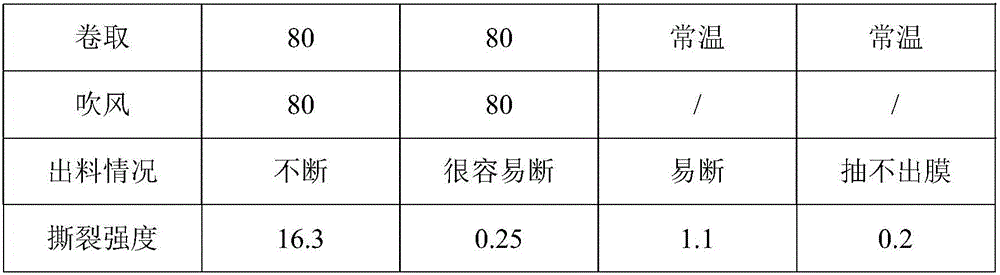

[0019] C. Pass the kneaded material obtained in step B through a twin-screw extruder at 120-180°C, an open mill at 120-180°C, a four-roll calender at 160-200°C, and a pull-off wheel at 120-160°C. , 80-160 ° C post-coiling, roll film concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com