Glue-coated cloth and manufacturing method thereof

A production method and adhesive tape technology, which is applied to adhesives, film/sheet adhesives, etc., can solve the problems of affecting the service life of the adhesive cloth, the adhesive surface layer is easy to open and bubble, and the base cloth cannot be damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

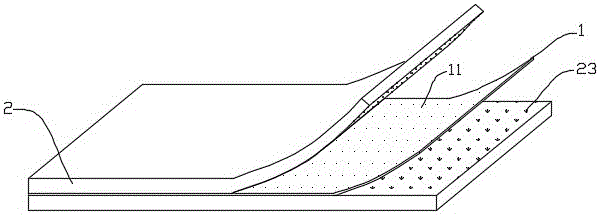

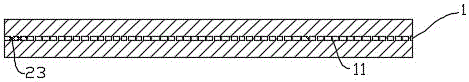

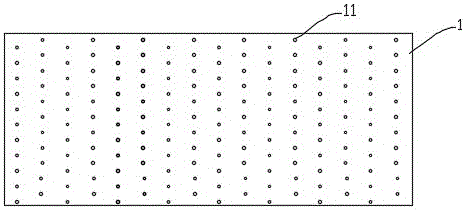

[0018] refer to Figure 1 to Figure 3 , the rubberized cloth includes a base cloth 1 and rubber surface layers 2 on both sides of the base cloth. The base cloth 1 is a fiber fabric, and glass fiber cloth, nylon cloth or canvas can be used according to functional requirements. The base cloth 1 is provided with a certain density of through-holes 11, a plurality of through-holes 11 are evenly distributed on the base cloth 1 in a sieve shape, the hole diameter is 0.3 to 2 mm, and the hole density is 2-10 per square centimeter. For the thicker base cloth 1 and the rubberized cloth with high pressure resistance requirements, generally the hole diameter is 1 to 2 mm, and the hole density is 5-10 per square centimeter. For the base cloth 1 that is thinner and requires less pressure-resistant rubberized cloth, the hole diameter is generally 0.3 to 1 mm, and the hole density is 2-5 per square centimeter. In order to facilitate processing and maintain the strength of the base cloth, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com