Hot melt adhesive formula and manufacturing method thereof

A production method and hot melt adhesive technology are applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc., to achieve the effects of environmental protection, high adhesion and reasonable components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

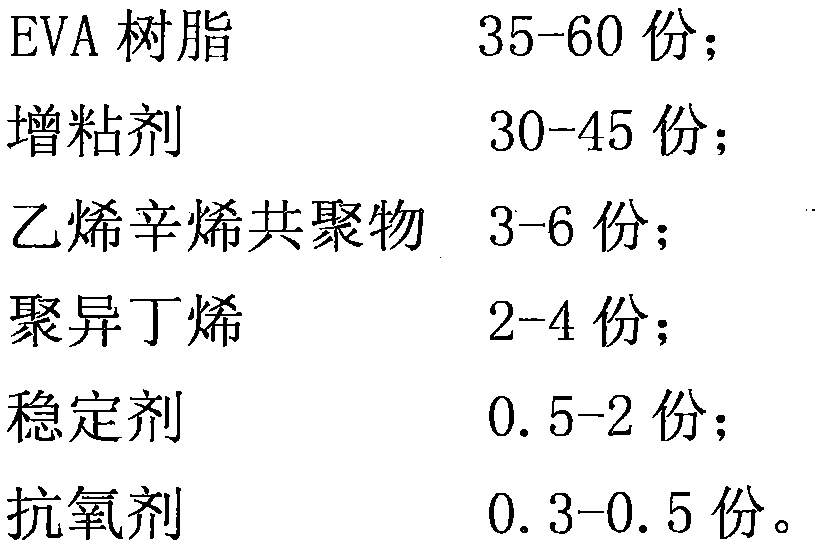

[0011] A hot-melt adhesive formula and a preparation method thereof, the composition of which comprises per hundred parts:

[0012]

[0013]

[0014] Stir EVA resin, ethylene octene copolymer, and polyisobutylene at 85°C for 15 minutes, add stabilizer and antioxidant, stir for 10 minutes, add tackifier, raise the temperature to 110°C and stir for 15 minutes, cool down to 80°C, pass Extruded by extruder, cut and cooled.

Embodiment 2

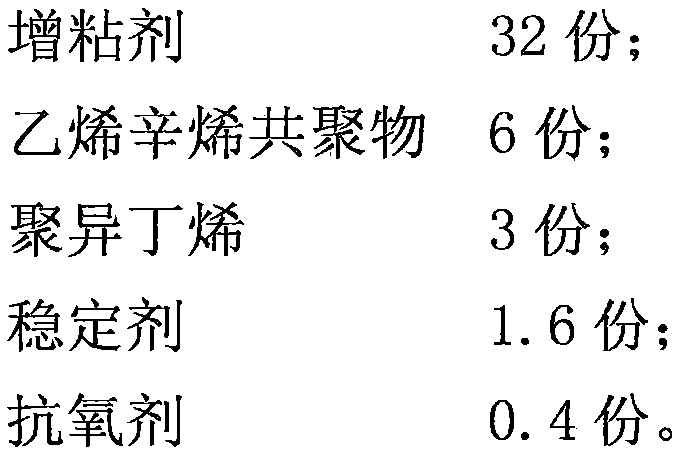

[0016] A hot-melt adhesive formula and a preparation method thereof, the composition of which comprises per hundred parts:

[0017]

[0018] Stir EVA resin, ethylene octene copolymer, and polyisobutylene at 90°C for 10 minutes, add stabilizer and antioxidant, stir for 5 minutes, add tackifier, raise the temperature to 110°C and stir for 15 minutes, cool down to 80°C, pass Extruded by extruder, cut and cooled.

Embodiment 3

[0020] A hot-melt adhesive formula and a preparation method thereof, the composition of which comprises per hundred parts:

[0021]

[0022] Stir EVA resin, ethylene octene copolymer, and polyisobutylene at 90°C for 8 minutes, add stabilizer and antioxidant, stir for 8 minutes, add tackifier, heat up to 110°C and stir for 12 minutes, cool to 80°C, pass Extruded by extruder, cut and cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com