Environment-friendly wallpaper adhesive and preparation method thereof

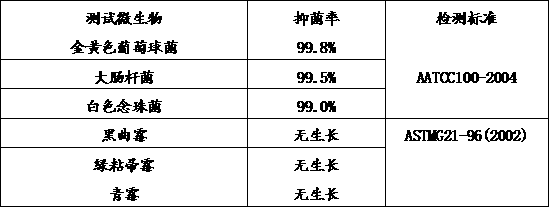

A kind of wallpaper glue, an environmentally friendly technology, applied in the field of building decoration materials, can solve the problems of easy mold growth, holes, and not reflected, and achieve the effect of not easy to change color, proper compatibility, and uniform wallpaper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Environment-friendly wallpaper adhesive, said adhesive includes A agent and B agent;

[0055] Described agent A is processed by the raw material of following weight part:

[0056] 60 parts of modified defatted soy flour paste, 6 parts of water-soluble dextran, 4 parts of leveling agent, 2 parts of organic bentonite, 1 part of auxiliary agent, which is a mixture of flame retardant powder and antistatic agent, water-soluble The quality of dextran is 10% of the quality of modified defatted soybean flour paste;

[0057] The preparation method of the modified defatted soybean powder paste is as follows: add defatted soybean powder, an appropriate amount of compound enzyme and an appropriate amount of deionized water into the reaction vessel, add acid to adjust the pH to 4, enzymatically hydrolyze at 35°C for 1 hour, and heat to 80°C ℃ inactivation for 5 minutes, cooled to 35 ℃, adding a coupling agent of 3% mass of defatted soybean flour and stirring for 0.5h, filtering to ...

Embodiment 2

[0066] Environment-friendly wallpaper adhesive, said adhesive includes A agent and B agent;

[0067] Described agent A is processed by the raw material of following weight part:

[0068] 80 parts of modified defatted soy flour paste, 8 parts of water-soluble dextran, 6 parts of leveling agent, 3 parts of organic bentonite, 3 parts of auxiliary agent, said auxiliary agent is flame retardant powder, nano negative ion powder and antistatic agent Equal mass mixture, the quality of water-soluble dextran is 10% of the quality of modified defatted soybean flour paste;

[0069] The preparation method of the modified defatted soybean powder paste is as follows: add defatted soybean powder, an appropriate amount of compound enzyme and an appropriate amount of deionized water into the reaction vessel, add acid to adjust the pH to 5, enzymatically hydrolyze at 40° C. for 1 hour, and heat to 90° C. Inactivate at ℃ for 8 minutes, cool to 40°C, add a coupling agent with 5% mass of defatted ...

Embodiment 3

[0078] Environment-friendly wallpaper adhesive, the adhesive includes agent A and agent B;

[0079] Described agent A is processed by the raw material of following weight part:

[0080] 70 parts of modified defatted soy flour paste, 7 parts of water-soluble dextran, 5 parts of leveling agent, 2.5 parts of organic bentonite, 2 parts of auxiliary agent, said auxiliary agent is an equal mass mixture of flame retardant powder and nano negative ion powder;

[0081] The preparation method of the modified defatted soybean powder paste is as follows: add defatted soybean powder, an appropriate amount of compound enzyme and an appropriate amount of deionized water into the reaction vessel, add acid to adjust the pH to 4.5, enzymatically hydrolyze at 38°C for 0.5h, and heat to Inactivate at 85°C for 6 minutes, cool to 38°C, add a coupling agent of 4% mass of defatted soybean flour and stir for 0.5h, filter to remove impurities, and concentrate in vacuum to a moisture content of 45% to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com