Large-volume backfill structure of hydraulic building

A hydraulic construction and large-volume technology, applied in filling and other directions, can solve problems such as poor economy, poor integrity, and increased investment, and achieve the effects of improving anti-seepage performance, fast construction speed, and accelerated construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

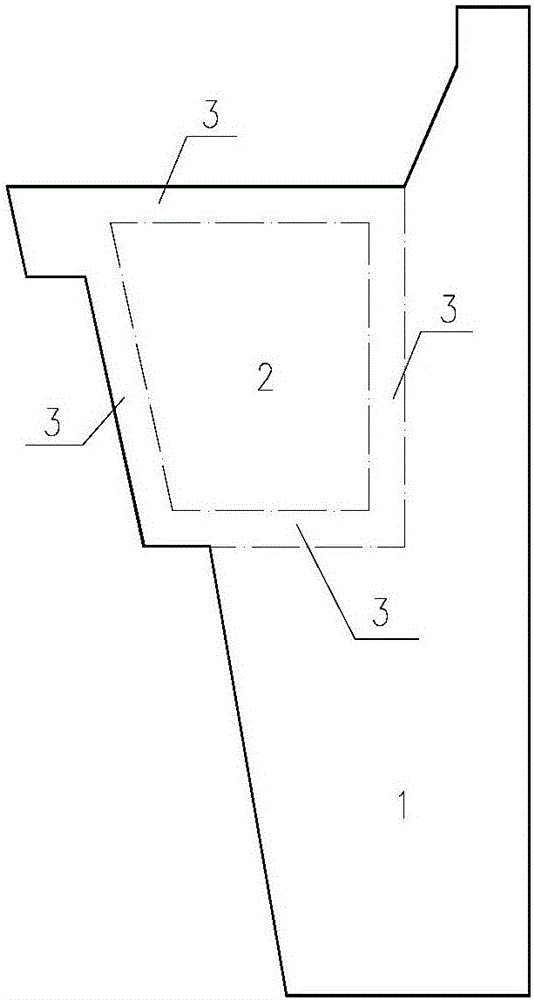

[0016] Such as figure 1 As shown, the large-volume backfill structure of a hydraulic structure of the present invention includes a concrete material area 1 located outside the structure to meet the requirements of structural strength and durability; a sand and gravel cementitious material area 2 located in the backfill area inside the structure; concrete material Metamorphic sand and gravel area 3 is set between the interface of area 1 and sand and gravel cementitious material area 2, and between the interface of sand and gravel cementitious material area 2 and the foundation.

[0017] The sand and gravel cementitious material area 2 needs to use compaction equipment and adopt layered rolling method for construction.

[0018] The area of the sand and gravel cementitious material area 2 meets the requirements of the rolling construction for th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com