Novel converter tool platform

A converter and tooling technology, applied in the field of new converter tooling platform, can solve the problems of narrow space, long construction period, waste of structural materials, etc., and achieve the effect of reasonable structure design, convenient disassembly and assembly, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

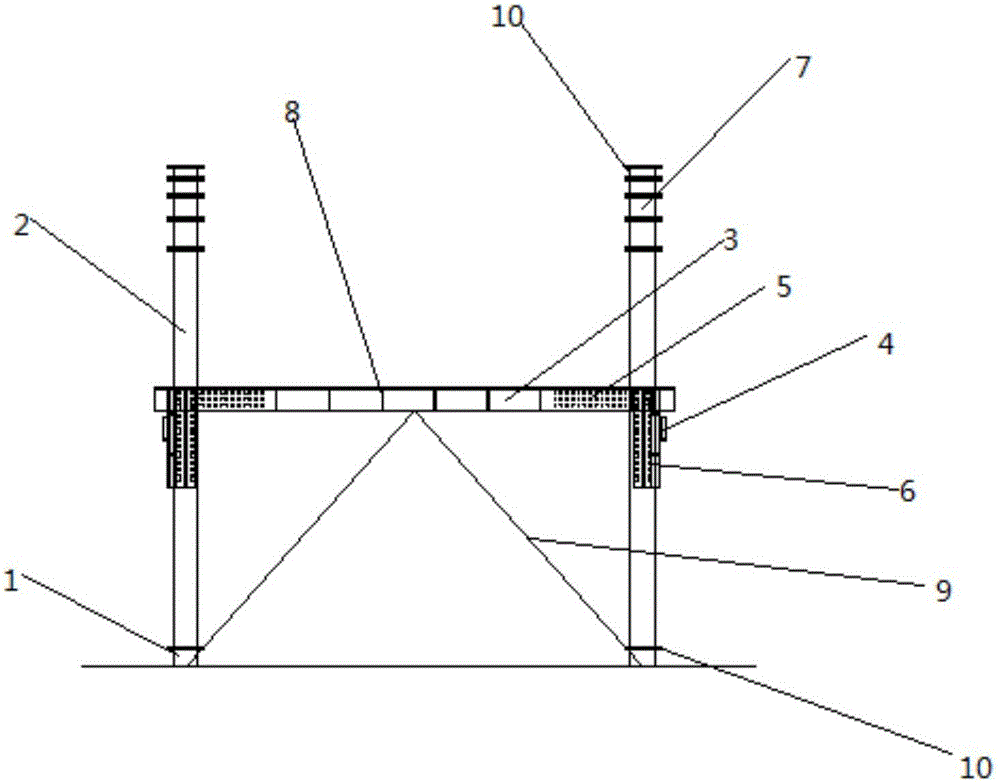

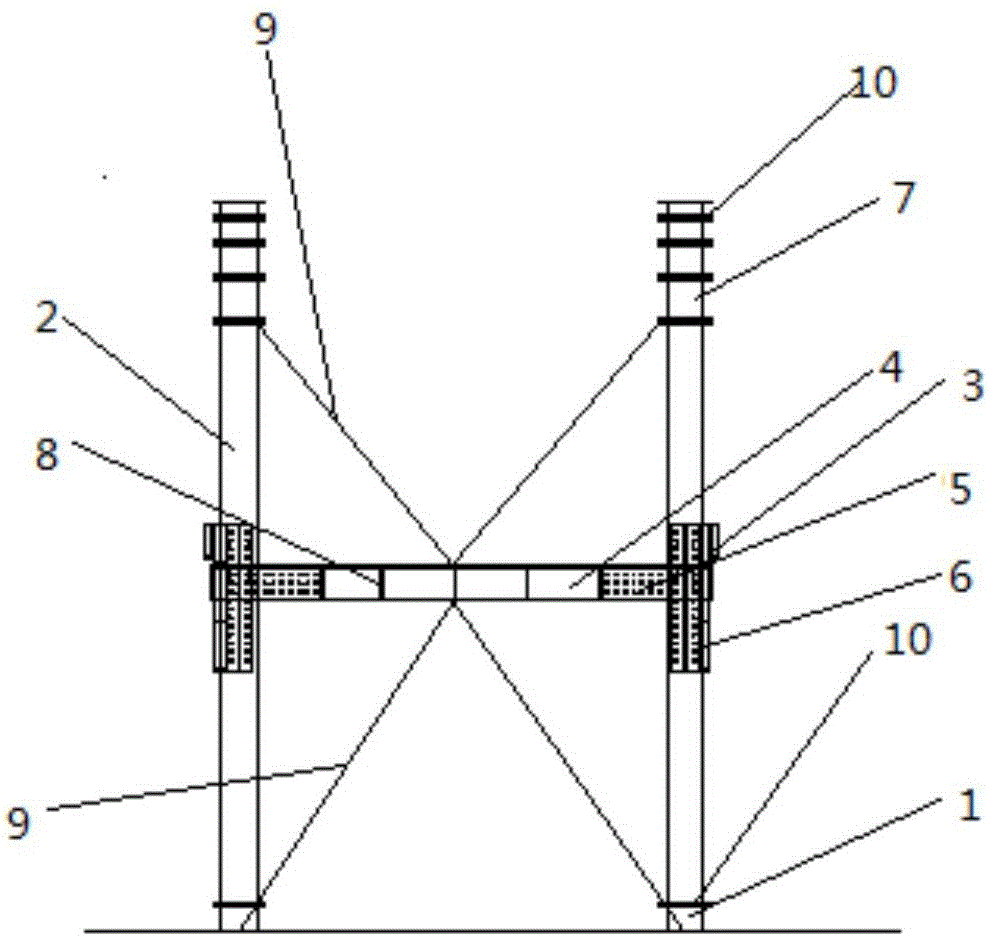

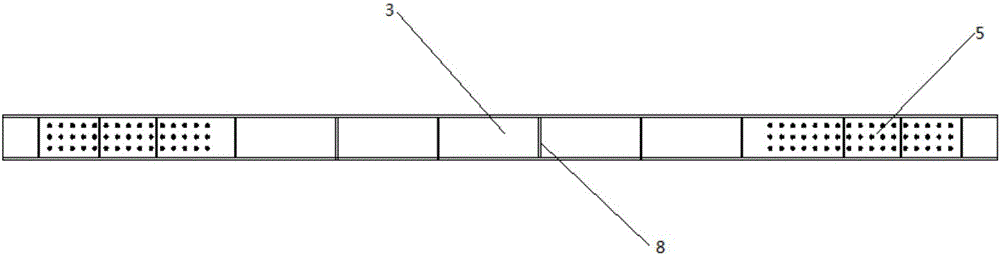

[0025] like Figure 1-5 As shown, the present invention provides a novel converter tooling platform, including a frame structure composed of adjustable steel columns, beam one 3 and beam two 4;

[0026] The adjustable steel column is formed by sequentially connecting the bottom column 1, the base column 2 and the adjustment column 7, and the base column 2 is fixed with a bolt reinforcement plate 6 for connecting the first beam 3 and the second beam 4, and the bolt reinforcement plate 6 is fixed on the base On the outer side of the column 2, the adjusting column 7 includes adjusting column sections with different heights;

[0027] The height adjustment of the adjustable steel column is realized by selecting adjustable column sections or combinations thereof with different heights;

[0028] Both ends of beam one 3 and beam two 4 have connection plates 5 . Both the connecting plate 5 and the bolt reinforcing plate 6 have a plurality of bolt holes, the connecting plate 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com