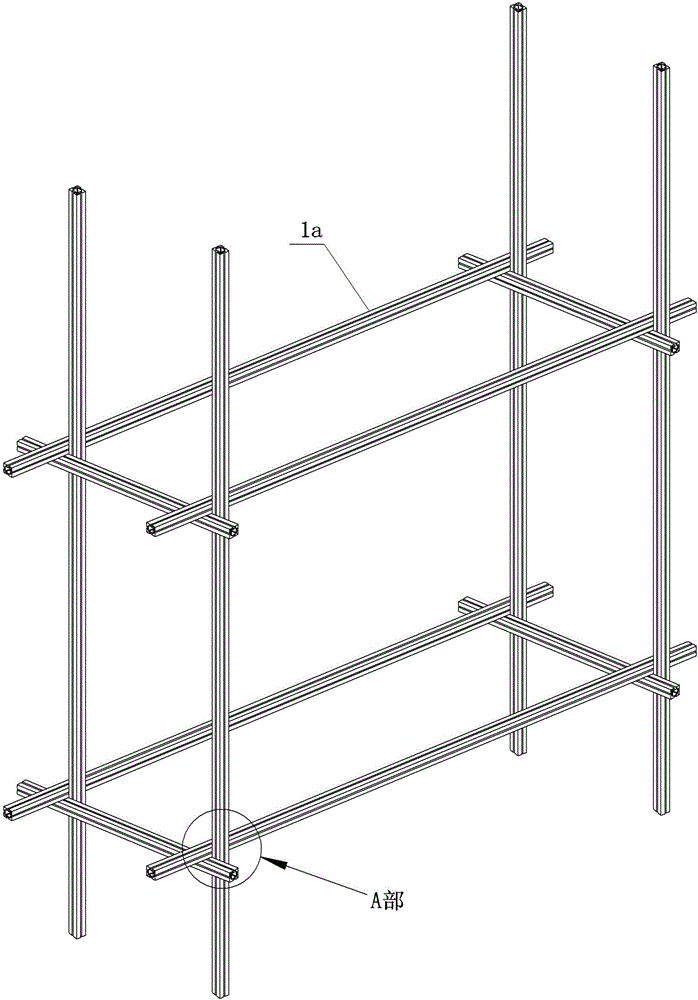

Internally connected type scaffold fastening and connecting structure thereof

A technology for connecting structures and scaffolding, which is applied in the connection of scaffolding, building structure support, building structure support, etc. It can solve the problems of difficult connection and low moment of inertia of round steel pipes, and achieve high construction efficiency, strong flexibility and stability Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

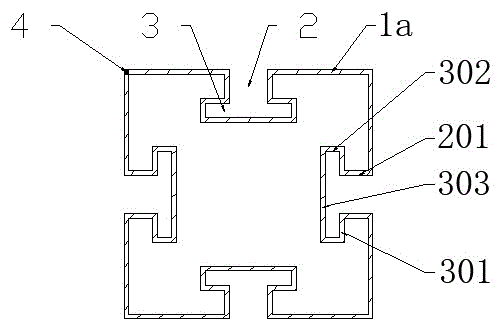

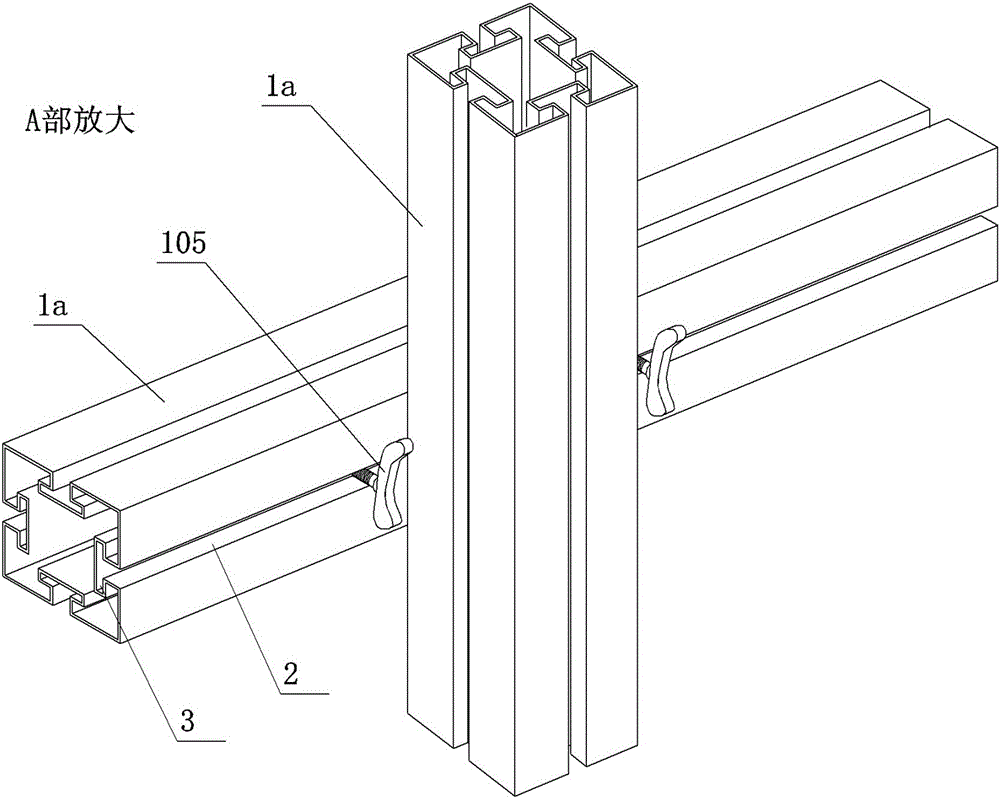

[0046] Embodiment 1: A kind of internally connected scaffold fastener, see Figure 2-Figure 4 , the two ends of a gap connection plate are respectively vertically connected with inner sleeve plates. The symmetrical outer side of each inner sleeve is respectively inwardly provided with cutouts, which divide the edge of the inner sleeve into two parts, the inner board and the outer board; the cutouts of the two inner sleeves are perpendicular to each other. Screw holes are provided on the inner plate and adjusting bolts are installed, and the end faces of the adjusting bolts are in contact with the inner surface of the outer plate.

[0047] Wherein, the inner sleeve plates located at both ends of the gap connecting plate are respectively rectangular inner sleeve plates, and the length directions of the two rectangular inner sleeve plates are perpendicular to each other.

Embodiment 2

[0048] Embodiment 2: another kind of internally connected scaffold fastener, see Figure 6 , On the basis of Embodiment 1, an anti-reversal mechanism is provided on the adjusting bolt. In the anti-reverse mechanism, a vertical connecting rod is vertically fixed at the end of the adjusting bolt, and a locking swing rod is hinged at the end of the vertical connecting rod.

Embodiment 3

[0049] Embodiment 3: Yet another internally connected scaffold fastener, characterized in that it includes a gap connecting plate, the two ends of the gap connecting plate are respectively vertically connected with inner sleeve plates, and the symmetrical outer side of each inner sleeve plate is welded with Shrapnel: The directions of the shrapnel of the two inner sleeves are perpendicular to each other, screw holes are arranged on the inner sleeves and adjusting bolts are installed, and the end faces of the adjusting bolts are in contact with the inner surface of the shrapnel.

[0050] An anti-reverse mechanism is arranged on the adjusting bolt. The anti-reverse mechanism is that a cam is hinged at the end of the adjusting bolt, and the cam is connected with a cam handle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com