Device and method for controlling thickness and flatness of concrete floor

A control device and thickness control technology, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems that the surface flatness cannot be effectively guaranteed, the thickness of the concrete floor is difficult to control, and the thickness of the floor is uneven. , to achieve the effect of reducing manual labor, reducing common floor leakage, and making it convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

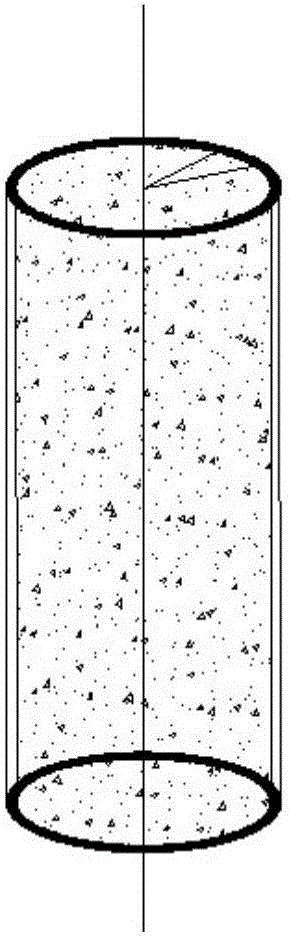

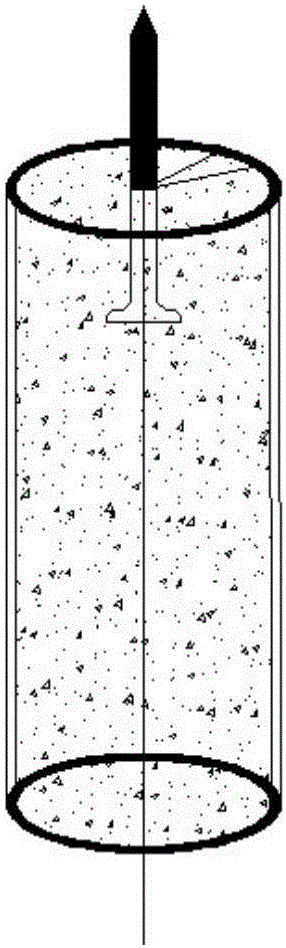

[0022] Such as Figure 1 to Figure 4 As shown, a concrete floor thickness and flatness control device mainly uses PVC plastic pipes as the device mold ( figure 1 ), a concrete cylinder is formed by pouring concrete in a mold, one end of the concrete cylinder is inserted with iron nails, and the nail head is exposed outside the concrete cylinder, and the height of the concrete cylinder is the thickness of the concrete floor to be poured. The diameter of the concrete cylinder is Ф50mm~Ф75mm. The tail of the iron nail is inserted into the concrete cylinder, and the exposed length of the iron nail head is 20-30 mm.

[0023] Such as Figure 5 As shown, in the control of the thickness and flatness of the impermeable concrete floor slab, two expansion water-stop rings are added to the outside of the concrete cylinder to achieve the effect of concrete water-stopping. The expansion waterstop ring is a 2cm×2cm micro expansion rubber waterstop ring.

[0024] The manufacturing method of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com