A preparation method for micron-scale ultra-thin metal sheets used for conductive adhesive fillers

A micron-scale, metal flake technology, applied in metal processing equipment, metal material coating technology, transportation and packaging, etc., can solve the problem of unable to meet the large demand of flake silver powder, uncontrollable shape of nano silver powder, and wide particle size distribution range and other issues, to achieve the effect of low production cost, good uniformity, and controllable thickness and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

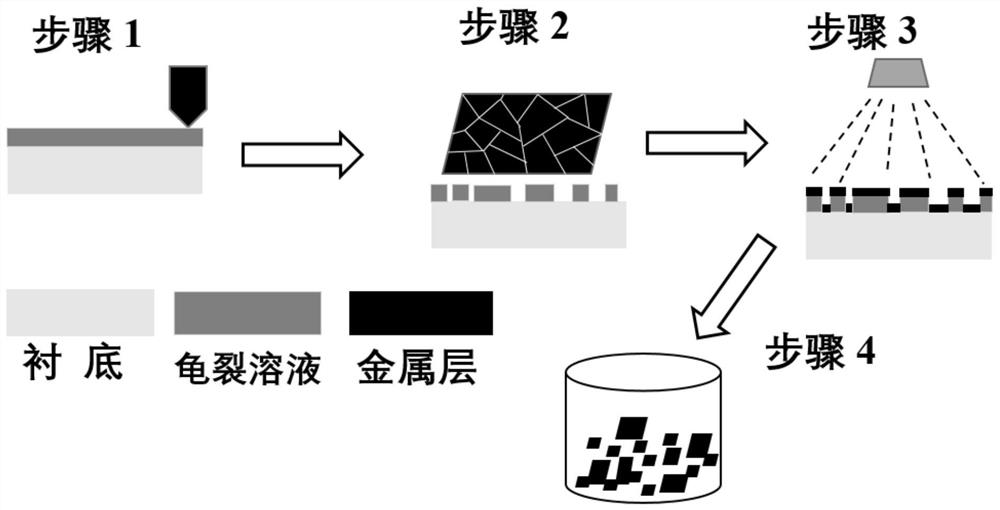

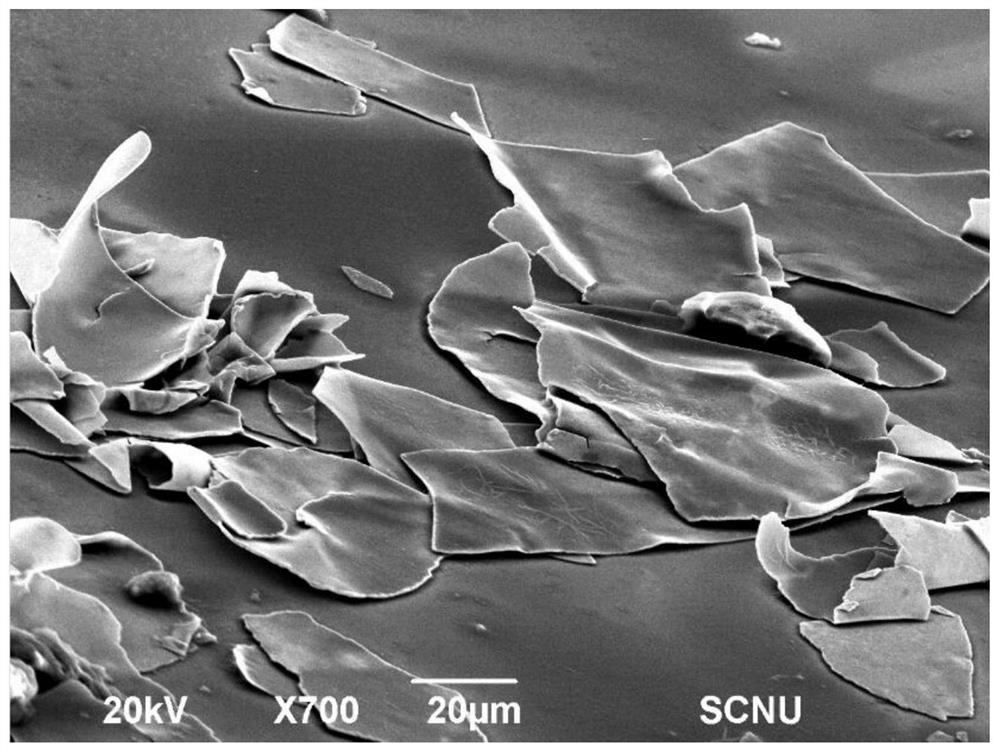

[0039] Such as figure 2 Shown is the preparation method for micron-sized ultra-thin metal sheets used for conductive adhesive fillers. The cracking material is protein powder, and the substrate is selected as flexible PET. figure 2 (1) Coating of cracking solution; (2) Natural cracking of the template; (3) Magnetron sputtering of metallic silver; (4) Separation and cleaning of metallic silver microchips.

[0040] Specific steps are as follows:

[0041] (1) Coating of cracking fluid

[0042]Mix protein powder with water and stir to make a cracking solution, in which the mass ratio of protein powder to water is 1:1. The coiled PET flexible substrate was pre-cleaned with ultrasonic waves, dried with nitrogen gas, and loaded on a coating machine for use. Turn on the coating machine, and the PET coil is cleaned by atmospheric plasma sputtering and coated with cracking liquid ( figure 2 shown in step 1). The coil speed is set to 1m / s, and the thickness of the coated cracking...

Embodiment 2

[0051] The present embodiment provides another preparation method for micron-scale ultra-thin metal sheets used for conductive adhesive fillers, the cracking material is nail polish CA600, and the substrate is selected as flexible PEN, wherein (1) coating of cracking liquid; 2) Natural cracking of the template; (3) Magnetron sputtering metal copper and silver; (4) Separating and cleaning the micron-sized copper-silver alloy metal sheet, the specific steps are as follows:

[0052] (1) Coating of cracking fluid

[0053] First, put the nail polish CA600 as cracking solution into a beaker and set it aside. Then the coiled PEN flexible substrate is cleaned by ultrasonic heating, and then dried by nitrogen gas. After drying, plasma cleaning is carried out. After cleaning, it is flatly spread on the coating machine. Install the coating cutter head, and use deionized water to adjust the uniformity of the cutter head. After the uniformity is adjusted, replace it with the cracking solu...

Embodiment 3

[0061] This embodiment provides a kind of preparation method that is used for the micron-scale ultra-thin metal sheet of conductive adhesive filler, and its cracking material is natural egg white aqueous solution, and substrate is selected as rigid glass, wherein (1) coating of cracking liquid; (2) ) natural cracking of the template; (3) magnetron sputtering metal copper; (4) separation and cleaning of micron-sized copper metal sheets, the specific steps are as follows:

[0062] (1) Coating of cracking fluid

[0063] Mix egg white with water, stir, and make a cracking liquid, in which the volume ratio of egg white to water is 2:1~3:1, put it into a beaker, and set it aside. The rigid glass substrate is cleaned by ultrasonic heating, and then dried by nitrogen gas. After drying, plasma cleaning is performed. After cleaning, it is tiled and fixed on the operating table.

[0064] The egg white aqueous solution was drop-coated on one end of the glass, and then scraped with a 40 μ...

PUM

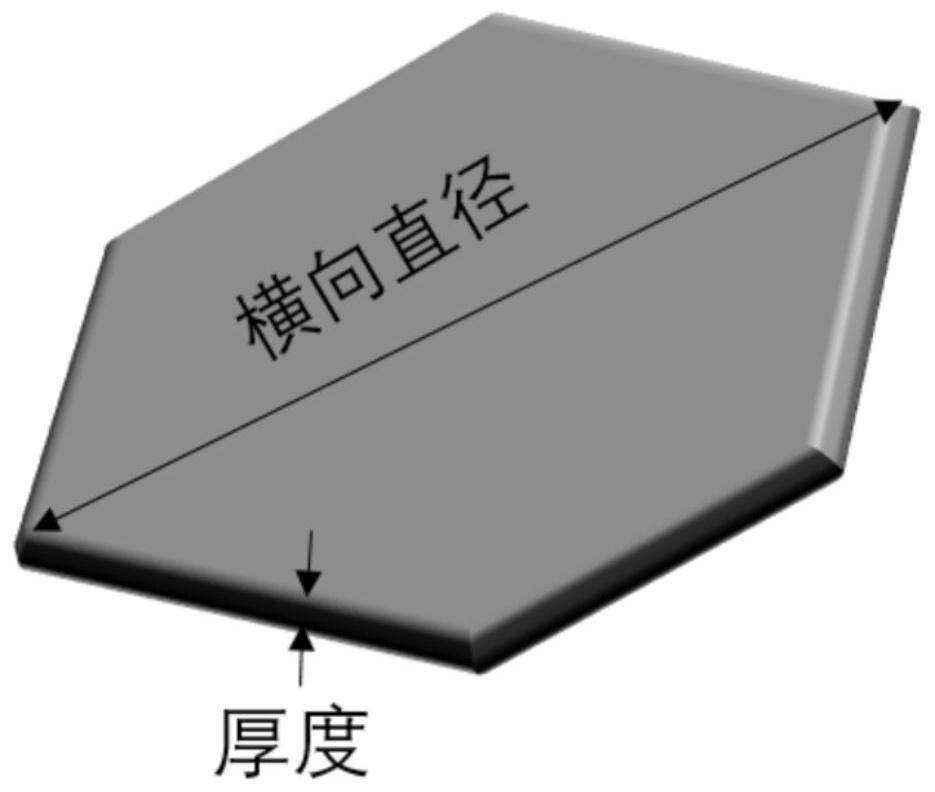

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com