Three-layer composite self-lubricating plate and manufacture method thereof

A self-lubricating and layer-combining technology, which is applied in the direction of engine lubrication, chemical instruments and methods, and layered products, can solve problems such as unstable bonding strength of the surface anti-friction layer, difficult processing technology, and large deformation of the plate, achieving The effect of easy control of thickness and dimension, high bonding strength and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

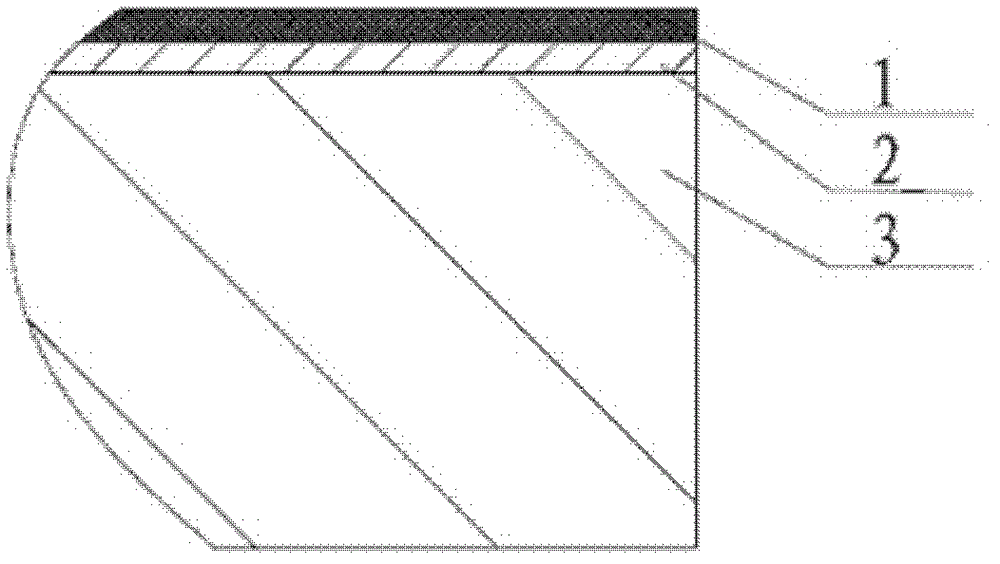

[0040] see figure 1 , The three-layer composite self-lubricating sheet of this embodiment is based on the SPCC cold-rolled steel plate as the substrate 3, the copper alloy layer 2 as the middle layer, and the friction-reducing and wear-resistant spraying layer 1 as the surface layer. The copper alloy layer 2 can be copper alloy with high wear resistance such as tin bronze or brass, such as CuSn5Pb5Zn5, HPb59-1, H62 and the like.

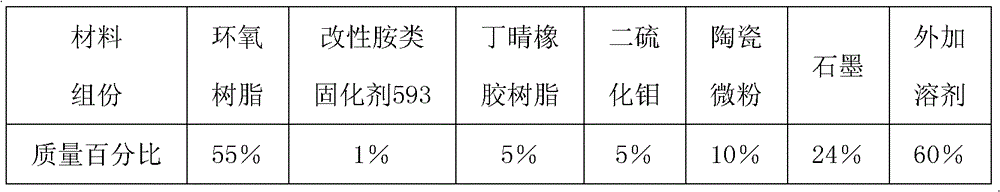

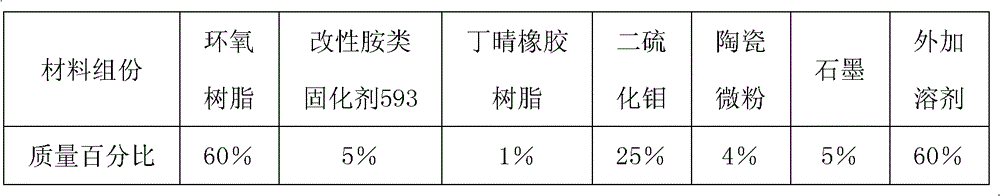

[0041] In the present embodiment, the three-layer composite self-lubricating plate, the composition of the friction-reducing and wear-resistant spraying layer 1 is as follows in mass percentage:

[0042] Molybdenum disulfide 5-25%, graphite 5-15%, alumina powder 0-1.0%, polytetrafluoroethylene powder 0-10%, curing agent 1-10%, toughening agent 1-5%, and the balance is epoxy resin;

[0043] The curing agent is an aliphatic amine curing agent, or an imidazole latent curing agent;

[0044] The toughening agent is polyamide resin or nitrile rubber res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com